Ramie fiber, air conditioning fiber, tencel fiber and polyester fiber blended thermoregulation fabric and manufacturing method thereof

A technology of air-conditioning fiber and ramie fiber, which is applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of easy wrinkling, poor suspension weight, poor wrinkle resistance, etc. Hair-like effect, anti-ultraviolet and anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

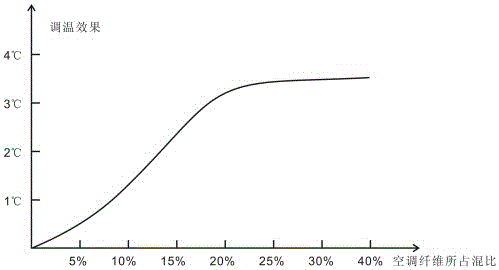

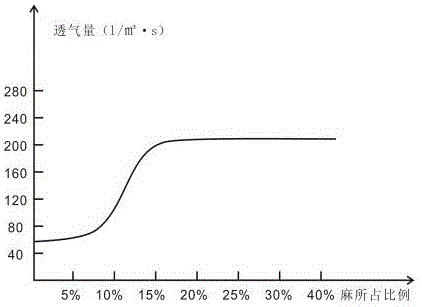

[0038] A blended temperature-regulating fabric of ramie fiber, air-conditioning fiber, tencel, and polyester fiber, the temperature-regulating fabric includes a blended yarn blended with ramie fiber, viscose-based air-conditioning fiber, tencel, and polyester fiber. The fineness of the spinning yarn is 60s, the blended yarns are connected by weaving, and the fabric structure is 2 / 1 twill weave; the components and mass percentages of the temperature-regulating fabric are: including 15% of the mass fraction Ramie fiber, massfraction is the air-conditioning fiber of 25%, massfraction is the tencel of 10%, and massfraction is the polyester fiber of 50%, and its preparation method comprises the steps:

[0039] (1) Soak raw ramie in 3mol / L aqueous hydrochloric acid solution at 35°C for 2 hours, rinse with clean water, then soak in clean water at a bath ratio of 6:1, and use alkaline pectinase (Nuo and Nord Alkaline Pectinase) to enzymatically degumming the raw ramie hemp obtained af...

Embodiment 2

[0054] A kind of ramie fiber and air-conditioning fiber, tencel, polyester fiber blended temperature-regulating fabric, described temperature-regulating fabric comprises blended yarn formed by blending ramie fiber, polyester-based air-conditioning fiber, tencel and polyester fiber, blended The fineness of the yarn is 60s, the blended yarns are connected by weaving, and the fabric structure is 2 / 1 broken twill weave; the components and mass percentages of the temperature-adjusting fabric are: including 10% Ramie fiber, massfraction is the air-conditioning fiber of 25%, massfraction is the tencel of 15%, and massfraction is the polyester fiber of 50%, and its preparation method comprises the steps:

[0055] (1) Soak raw ramie in hydrochloric acid aqueous solution with a concentration of 2mol / L at 40°C for 2 hours, rinse it with clean water, then soak it in clean water at a bath ratio of 6:1, and use alkaline pectinase (Nuo and Nord Alkaline Pectinase) to enzymatically degumming ...

Embodiment 3

[0066] A blended temperature-regulating fabric of ramie fiber, air-conditioning fiber, tencel, and polyester fiber, the temperature-regulating fabric includes a blended yarn blended with ramie fiber, viscose-based air-conditioning fiber, tencel, and polyester fiber. The fineness of spinning is 60s, the blended yarns are connected by weaving, and the fabric structure is 2 / 1 twill weave; the components and mass percentages of the temperature-regulating fabric are: including 20% by mass fraction Ramie fiber, massfraction is the air-conditioning fiber of 20%, massfraction is the tencel of 15%, and massfraction is the polyester fiber of 45%, and its preparation method comprises the steps:

[0067] (1) Soak raw ramie in 3.5mol / L aqueous hydrochloric acid solution at 30°C for 2 hours, rinse with clean water, then soak in clean water at a bath ratio of 6:1, and use alkaline pectinase ( Novo Nordisk Alkaline Pectinase) enzymatically hydrolyzes and degummes the raw ramie hemp obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com