polymer composition

A technology of composition and polymer, which is applied in the field of polymer composition and can solve problems such as unavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

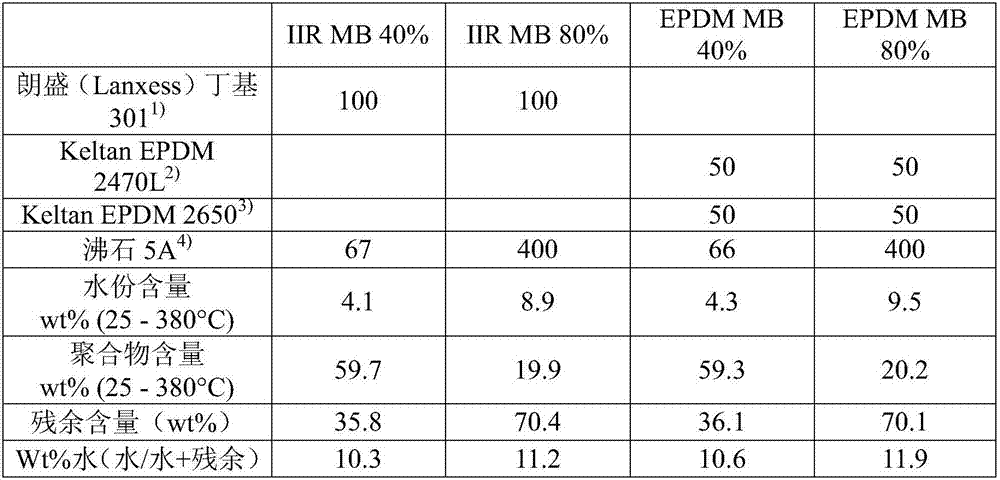

[0075] In order to improve the preparation of rubber compositions, it is desirable that the metal halide is further complexed with a complexing agent such as water, alcohol and ether. Such complexed metal halides have improved solubility and dispersibility in rubber compositions. A preferred example is tin dichloride dihydrate. The preferred amount of metal halide as activator package iii) is from 0.25 to 5.0 parts, preferably 0.5 to 2 parts, per 100 parts of elastomeric polymer i).

[0076] In another preferred embodiment of the invention, the activator package iii) comprises a halogenated organic compound.

[0077] Suitable halogenated organic compounds are those from which the hydrogen halide is split off in the presence of the metal compound.

[0078] Halogenated organic compounds include, for example, polymers or copolymers of vinyl chloride and / or vinylidene chloride and other polymerizable compounds, halogen-containing plastics, such as polychloroprene; halogenated, s...

example

[0112] general program

[0113] The zeolite / polymer masterbatch compositions of the examples were prepared using an internal mixer (Shaw K1 Mark IV Intermix) having a capacity of 3 liters with intermeshing rotating blades and an onset temperature of 25°C. Zeolite 5A was weighed and the zeolite / polymer masterbatch mixed for no more than 10 minutes thereafter. The elastomeric polymer is first introduced into the mixer and allowed to comminute for a period of 30 seconds using a rotor speed of 45 rpm before adding the zeolite 5A powder (which is an aluminosilicate powder with a particle size below 50 μm), at a rate of less than A moisture content of 1.5 wt% was supplied. Mixing was carried out maintaining the same rotational speed until a batch temperature of 140°C was achieved for the 40wt% masterbatch, taking 8 minutes of total mixing time, and 155°C for the 80wt% masterbatch, taking a total mixing time of 13 minutes, at which point the batches were Once removed from the inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com