Smelly-removing white carbon powder with high whiteness and method for producing the same and use thereof

A manufacturing method and technology of white carbon, which is applied in the field of white carbon powder manufacturing, can solve the problems that the content of bamboo charcoal powder cannot be reduced, the space for improving whiteness is limited, color difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

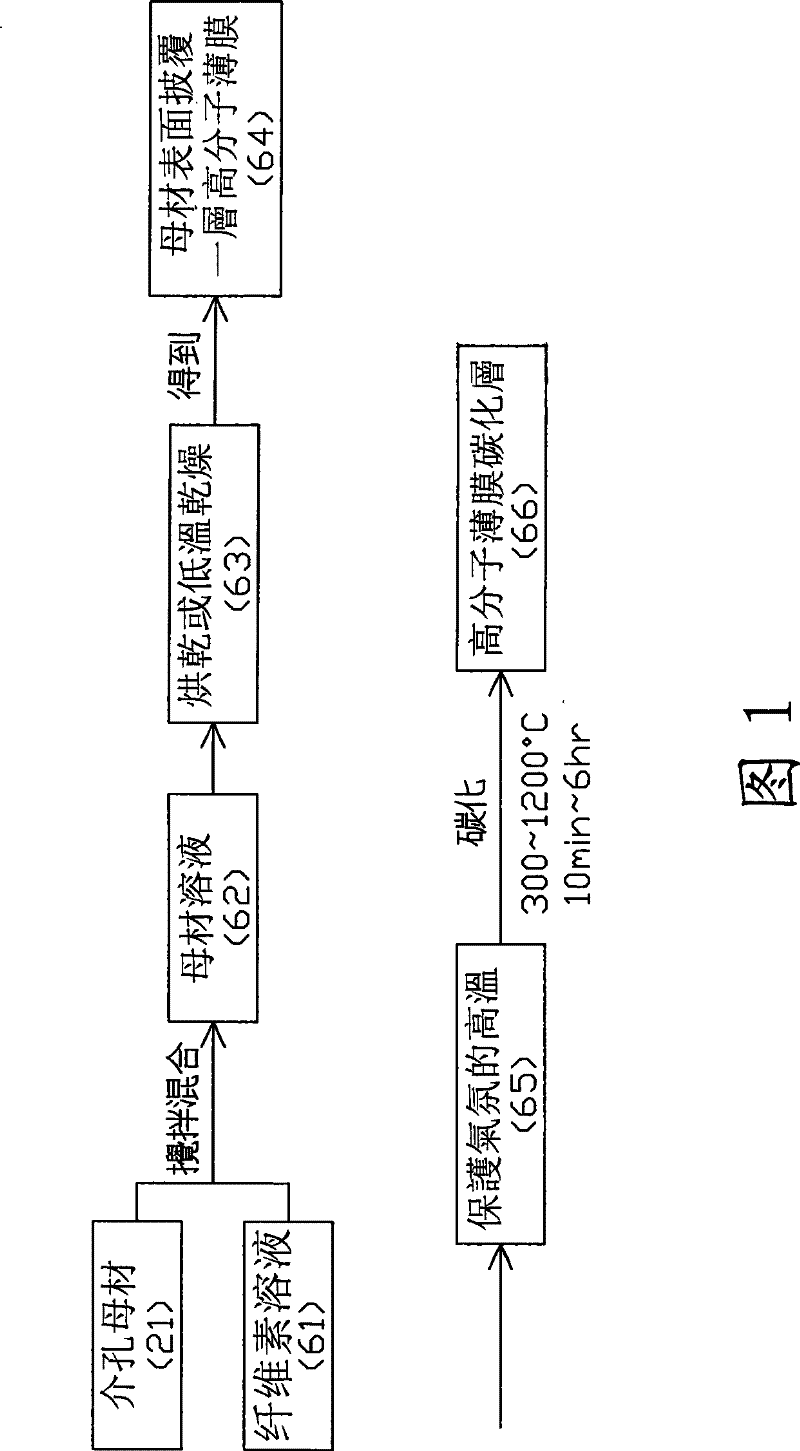

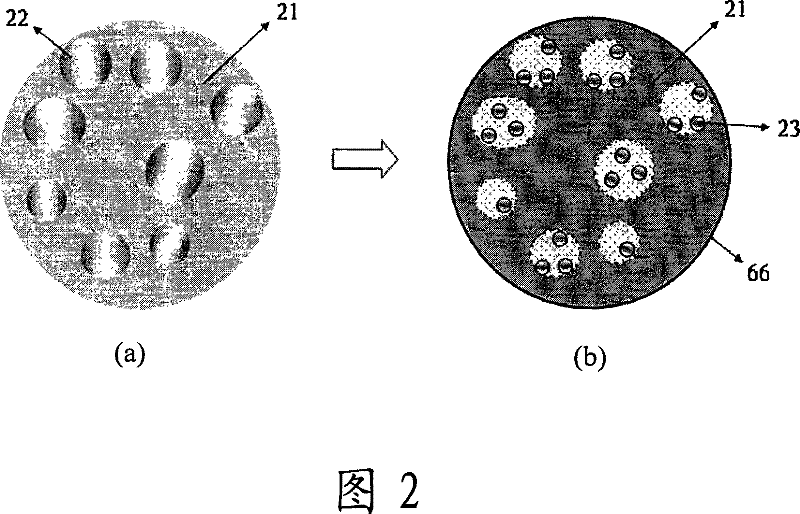

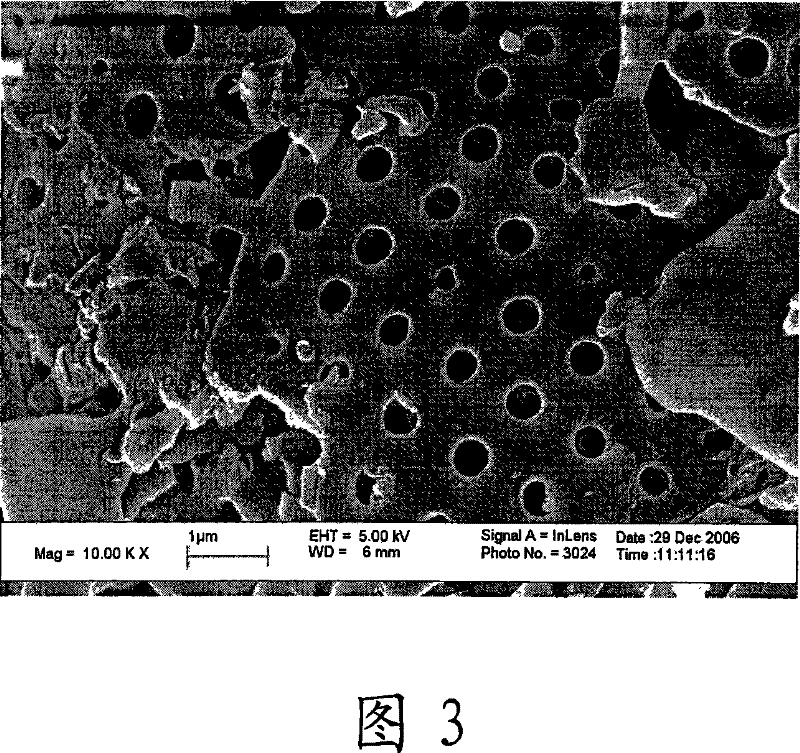

[0038] see figure 1 As shown, the present invention provides a kind of manufacturing method of deodorizing white carbon powder and fiber, and it is to use the high-porosity mesoporous material powder with high whiteness as mesoporous base material 21, then described mesoporous base material 21 and the cellulose solution 61 are uniformly stirred and mixed to form the base material solution 62 (natural cellulose and methyl cellulose can be dissolved in water, the cellulose powder can be dissolved in the water by adding the cellulose powder and stirring, and the cellulose can be dissolved in the water by proper heating It can also accelerate the dissolution rate. Only cellulose with high carbon content needs to use oily solvent, adding high carbon content cellulose to oily solvent, heating and stirring can produce dissolution effect.) Please refer to figure 2 (a), image 3 As shown, the original whiteness of the mesoporous base material 21 is 50-95, and the powder particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com