Alkali recovery device of jean mercerizing process weak alkali liquor

A recovery device and light alkali technology, applied in mercerizing, textile material processing, textile processing machine accessories, etc., can solve the problems of increasing difficulty and processing cost, high cost of acid neutralization, and inability to comprehensively utilize, etc., to achieve environmental protection and safe production Efficiency, high steam-water ratio and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

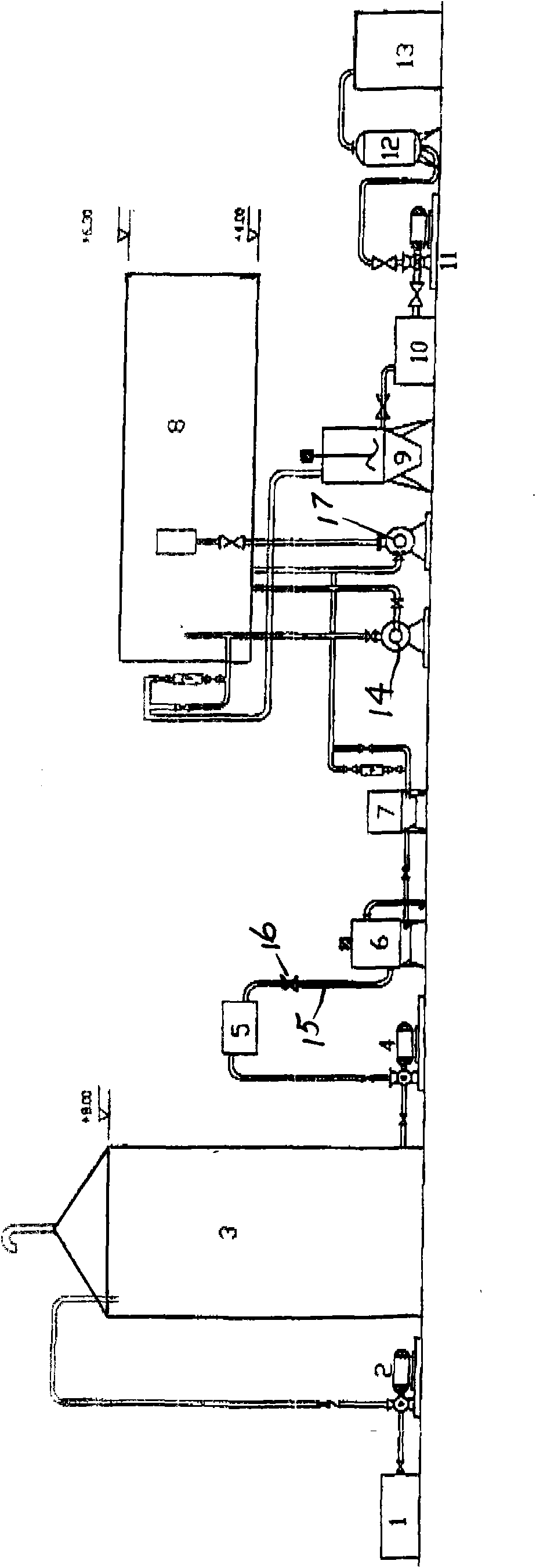

[0050] The second specific implementation mode, as attached figure 1 shown.

[0051] An alkali recovery device for light lye in the denim wiring light process. When the expander evaporator 8 is arranged on a high-level platform, the outlet of the sand filter 7 is connected to the expansion evaporator 8 through a light lye circulation pump 17 . When the expansion evaporator 8 is arranged on a higher platform than the stirring decolorizer 9, the outlet of the expansion evaporator 8 is directly connected to the inlet pipeline of the stirring decolorizer 9. Other than that, the others are the same as one of the specific embodiments.

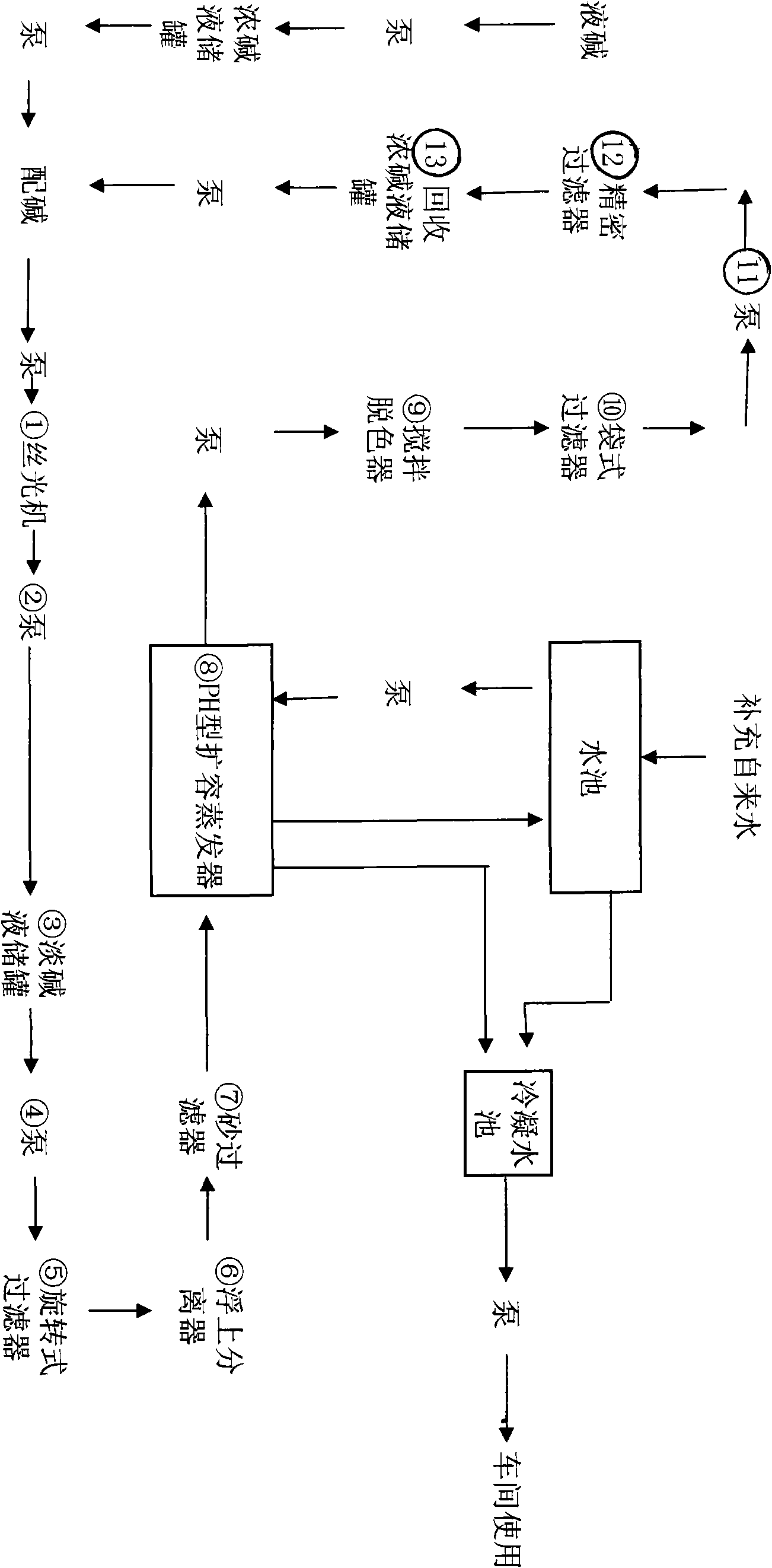

[0052] See attached figure 2 , the brief description of technological process of the present invention is:

[0053] 1. The mercerizing machine 1 produces waste lye, which is sent to the light lye storage tank 3 through the pump 2 for storage. The light lye storage tank 3 is equipped with a sewage overflow pipe, and the storage capacity is about 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com