All-cotton fabric imitated tencel treating process

A treatment process and cotton fabric technology, applied in the field of textile printing and dyeing, can solve the problems of mass population not consuming Tencel, high price and high cost of Tencel, and achieve the effect of cool hand feeling, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

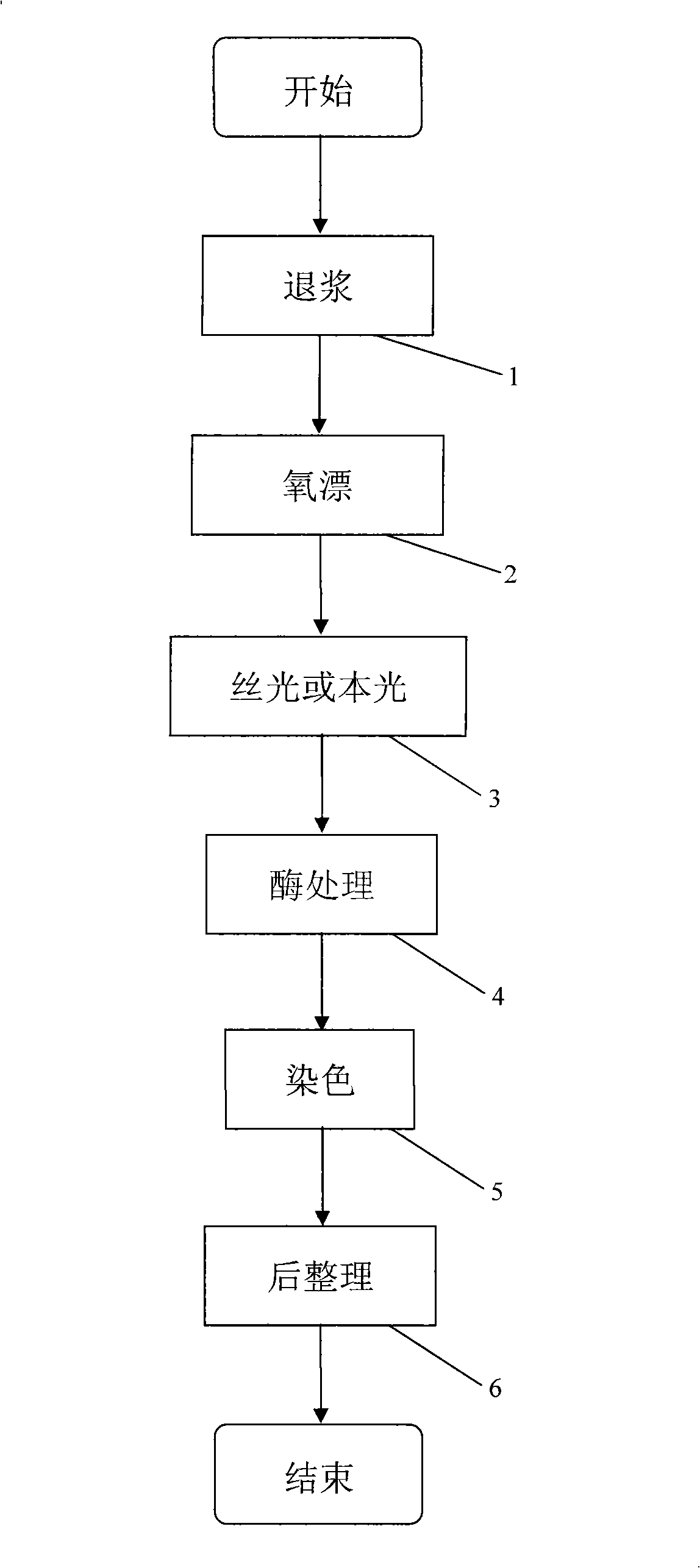

[0023] Such as figure 1 As shown, the cotton fabric imitation tencel treatment process includes the following steps in turn:

[0024] Desizing 1: The weight of the cloth is a, and 7658 amylase is used to desizing the cloth with alkali.

[0025] Oxygen bleaching 2: Put the desized fabric into the hydrogen peroxide mixed solution, and add Na 2 CO 3 , adjust the pH value between 10 and 10.5. The hydrogen peroxide mixed solution contains 4-4.5 g / l hydrogen peroxide, 2.8-3.2 g / l stabilizer, and 2.8-3.2 g / l chelating dispersant. The hydrogen peroxide mixed solution preferably contains 4.2g / l of hydrogen peroxide, 3g / l of stabilizing agent, and 3g / l of chelating dispersant.

[0026] Mercerized or original light 3: Use 220-240g / l liquid alkali, soak the alkali for 25-30s, then apply cloth clips to expand the width, then pass through the liquid alkali recovery tank, wash with four compartments of 85°C hot water and a Rinse with cold water and dry to ensure that the pH value of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com