Low-foam laundry detergent composite facilitating rinsing

A technology for compositions and laundry detergents, applied in the directions of detergent compositions, soap detergent compositions, surface-active non-soap compounds and cleaning compositions, etc., can solve the problems of difficult rinsing, excessive foam and the like, and achieve easy rinsing, Low total foam and quick wash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

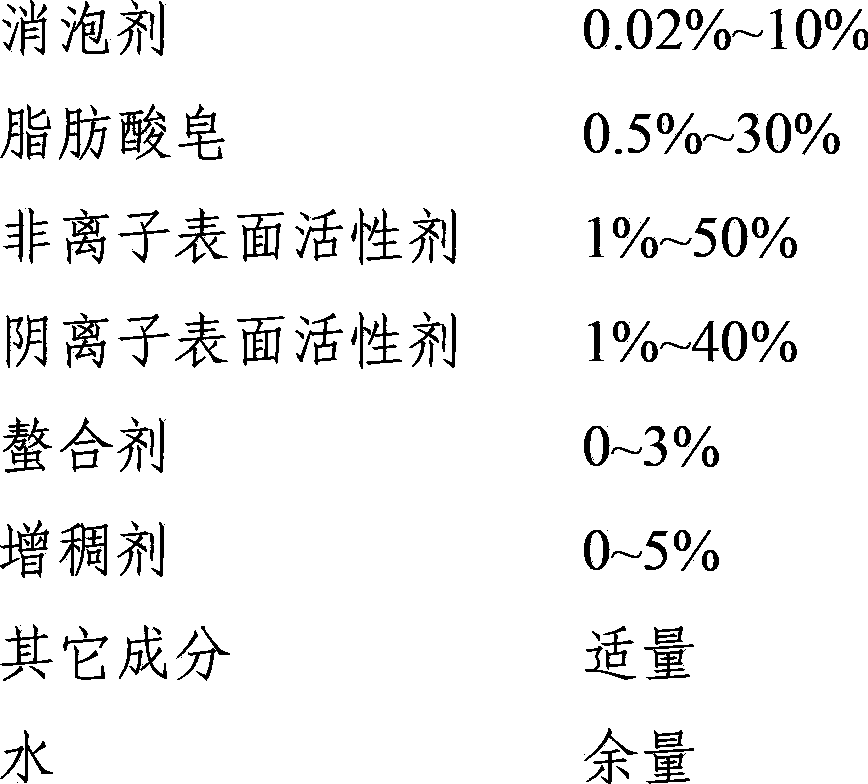

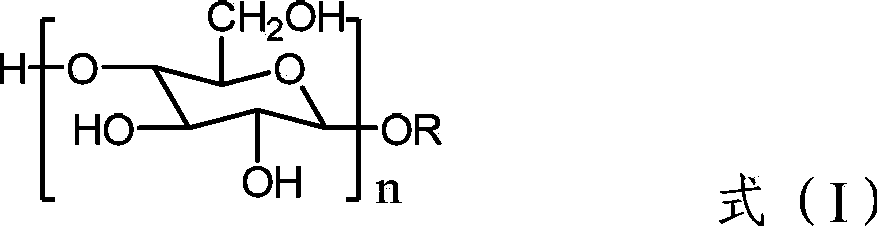

[0038] Embodiment one low-foaming easy-rinsing laundry detergent composition

[0039] The formulation of the laundry detergent composition is shown in Table 1.

[0040] Table 1 laundry detergent composition formula

[0041] serial number

[0042] Preparation method: Add KOH to an appropriate amount of deionized water, heat to about 60°C, add coconut oil fatty acid while stirring to completely neutralize, then add AES, MES, AEO7, APG and 6501 surfactants in sequence, and stir until Dissolve completely and the system is uniform, cool down to about 50°C, add EDTA-2Na, sodium citrate and whitening agent, stir and dissolve until the system is uniform, cool down to about 40°C, add simethicone defoamer (Y-14865) After stirring and dispersing evenly, add preservatives, pigments, flavors, etc. in turn. Stir until the system is uniform, and finally add deionized water, adjust the pH to 8.0~9.0 with KOH, adjust the viscosity to an appropriate range with NaCl, and stir evenly....

Embodiment 2

[0043] Embodiment two low-foaming laundry detergent compositions that are easy to rinse

[0044] The formulation of the laundry detergent composition is shown in Table 2.

[0045] Table 2 laundry detergent composition formula

[0046] serial number

[0047] The preparation method is the same as that described in Example 1.

Embodiment 3

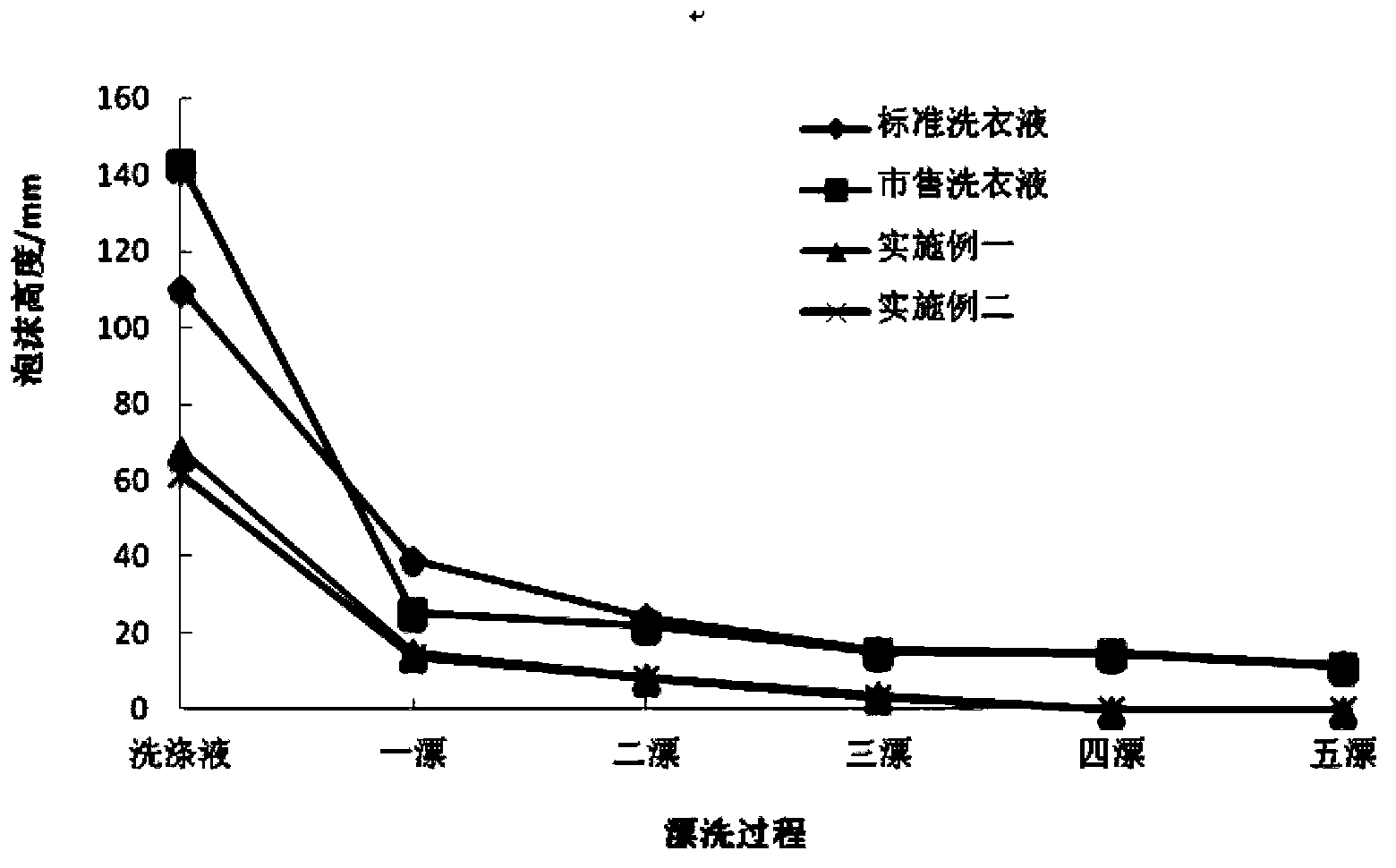

[0048] Example 3 Evaluation Test of the Low-foaming and Easy-rinsing Performance of the Laundry Liquid Composition of the Present Invention (Roche Foam Method)

[0049] 1 Reagents and materials

[0050] 1.1 New pure cotton knitted T-shirt (hereinafter referred to as: T-shirt);

[0051] 1.2 Magnesium chloride (MgCl 2 ·6H 2 O), anhydrous calcium chloride, analytically pure;

[0052] 1.3 standard laundry detergent, embodiment one and embodiment two laundry detergents and commercially available laundry detergents.

[0053] Refer to Table 3 for the formula, raw material specifications and preparation requirements of the standard laundry detergent.

[0054] Table 3 Standard Laundry Liquid Formula and Raw Material Specifications

[0055]

[0056] Preparation method: add various ingredients in a certain amount of water in turn, stir and dissolve (heating if necessary), adjust the pH to 8.5~9.0 with sodium hydroxide, and make up the water.

[0057] 2 Instruments and equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com