Non-powder treating agent for gloves made of latex

A latex glove and treatment agent technology, which is applied in the field of chemicals, can solve the problems of poor surface adhesion, low quality, and influence on coating quality of latex gloves, so as to improve coating quality and production efficiency, good slipperiness and Anti-blocking, good coating quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

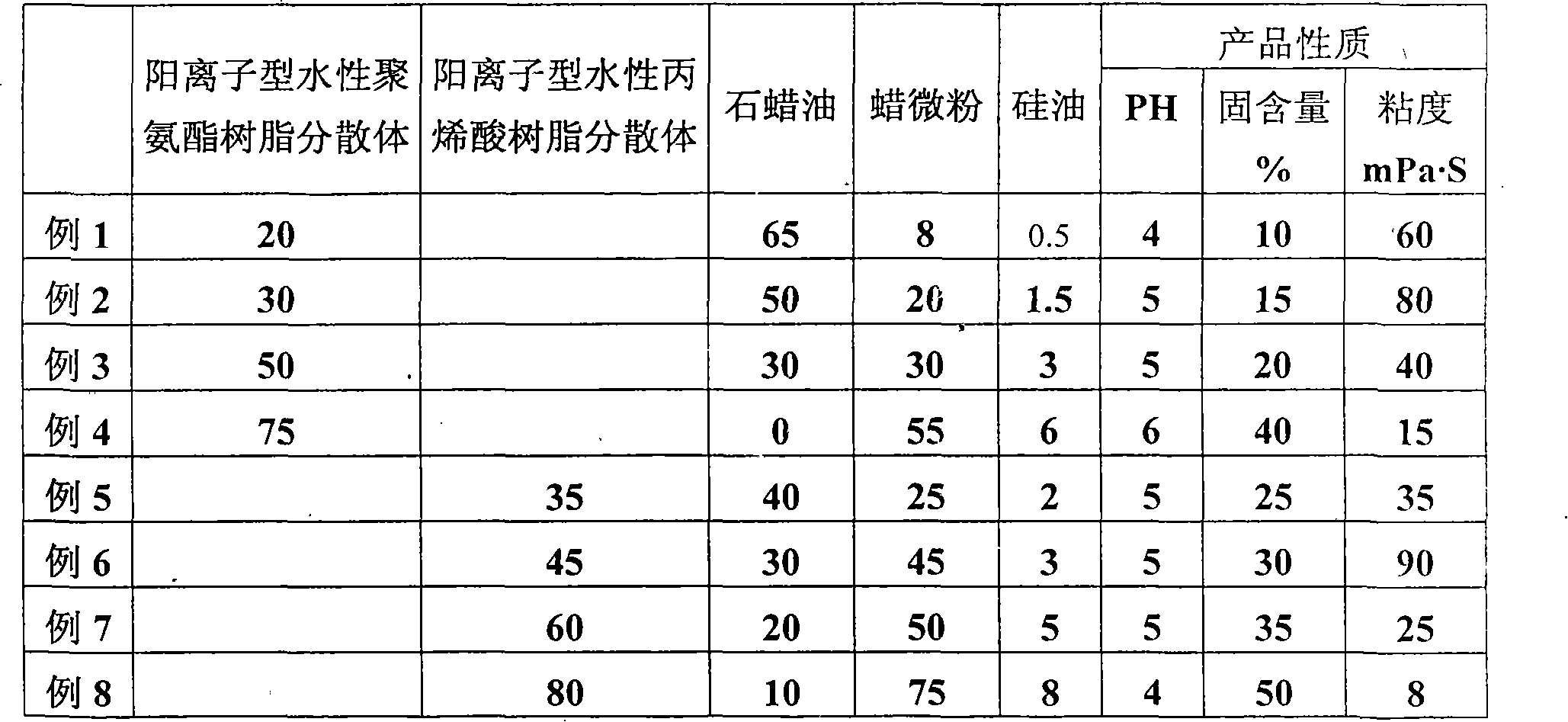

[0009] Product properties: PH4~6, solid content 15~35%, viscosity 10~40mPa·S;

[0010] The preferred ratio is 30-65 parts of cationic water-based resin, 20-50 parts of paraffin oil, 20-55 parts of wax micropowder, and 2-8 parts of silicone oil;

[0011] Cationic water-based resins are preferably cationic water-based polyurethane resins and cationic water-based acrylic resins;

[0012] Paraffin oil, wax micropowder and silicone oil are preferably cationic or nonionic, and have good compatibility with cationic water-based resins and match each other.

[0013] Batch production is adopted, and the raw materials used in batches are mixed in proportion and fully stirred evenly.

[0014] Components contained in each embodiment, the ratio of parts and product properties are as shown in Table 1, totally 8 examples:

[0015] Table I

[0016]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com