Synthesis method of cocoamidopropyl-2-hydroxyl-3-sulfopropyl betaine

A technology of sulfopropyl beet and cocamidopropyl, which is applied in the field of synthesis of zwitterionic surfactants in organic chemistry, to achieve the effects of reducing irritation, good calcium soap dispersion, and good hard water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

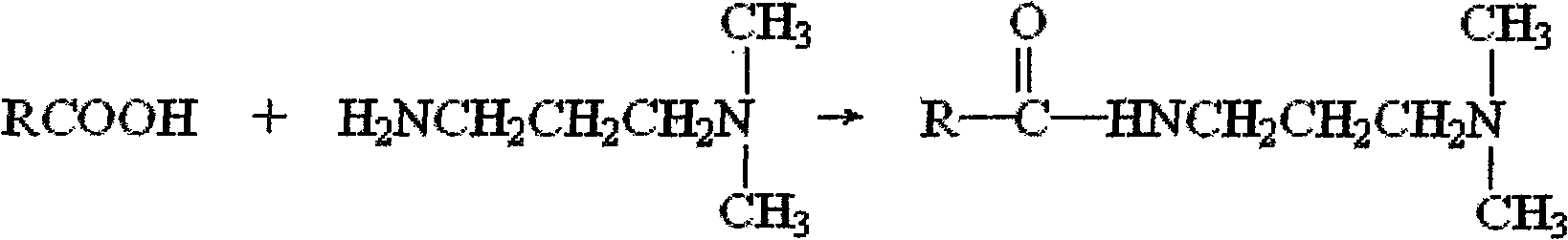

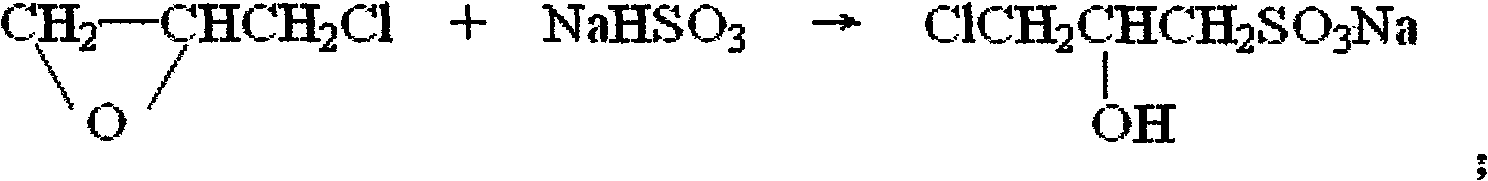

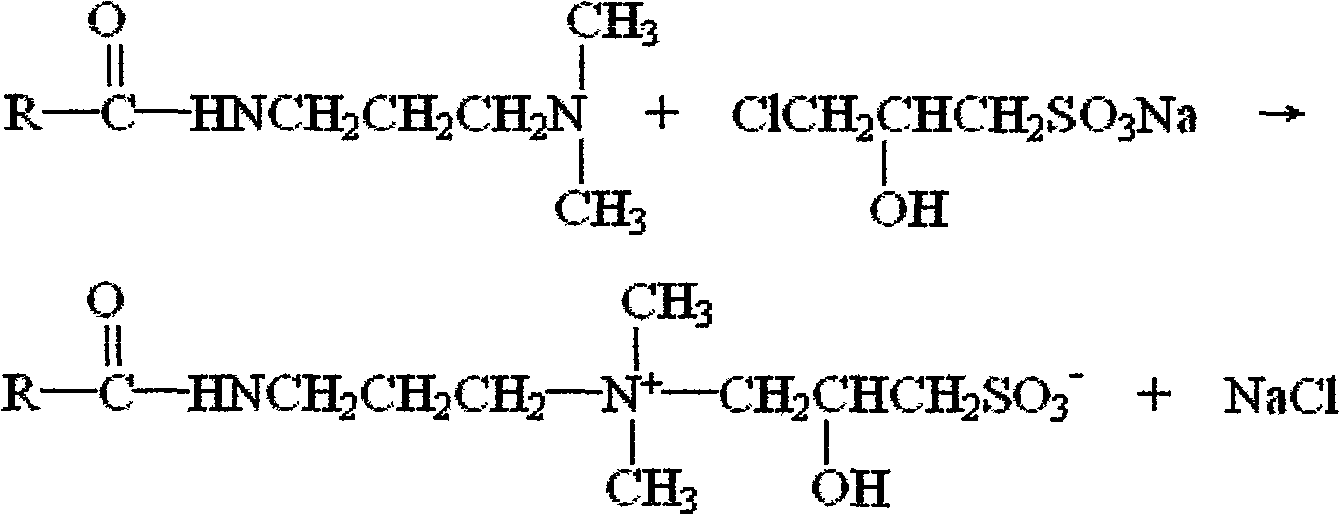

Method used

Image

Examples

Embodiment 1

[0025] Step 1 of this example: add 500kg of coconut oil fatty acid (purchased from Shandong Boxing China Resources Oleochemical Co., Ltd.) Complete the heat preservation reaction for 4.0h. Then, the reaction was carried out at a pressure of 20 Pa and a temperature of 200° C. for 4.0 hours to obtain the intermediate cocamide.

[0026] Step 2: Add 222kg of epichlorohydrin into the reaction kettle, stir and heat to 85-90°C, start to add 250kg of anhydrous sodium bisulfite in batches, and keep warm for 8.0 hours to obtain the intermediate chlorohydroxypropyl sulfonic acid sodium.

[0027] Step 3: Add 667kg of intermediate cocamide into the reaction kettle, heat to 85-90°C, add 11kg of potassium hydroxide, start to add 434kg of intermediate sodium chlorhydroxypropyl sulfonate in batches, and keep warm for 8.0 hours after adding. The target product cocamidopropyl-2-hydroxyl-3-sulfopropyl betaine was obtained with a molecular weight of 429.

Embodiment 2

[0029] Step 1 of this embodiment: add 500kg coconut oil fatty acid (purchased from Shandong Boxing China Resources Oleochemical Co., Ltd.) in the reaction kettle, stir and heat to 60~62 ℃, start to drop 295kgN, N-dimethylpropylenediamine, After adding, keep warm and react for 2.0h. Then, the reaction was carried out at a pressure of 100 Pa and a temperature of 160° C. for 3.0 hours to obtain the intermediate cocamide.

[0030] Step 2: Add 222kg of epichlorohydrin into the reaction kettle, stir and heat to 60-65°C, start to add 287kg of anhydrous sodium bisulfite in batches, and keep warm for 5.0 hours to obtain the intermediate chlorohydroxypropyl sulfonic acid sodium.

[0031] Step 3: Add 667kg of intermediate cocamide into the reaction kettle, heat to 80-85°C, add 46kg of potassium hydroxide, start to add 447kg of intermediate sodium chlorhydroxypropyl sulfonate in batches, and keep warm for 4.0 hours after adding. The target product cocamidopropyl-2-hydroxyl-3-sulfopropyl...

Embodiment 3

[0033] Step 1 of this example: add 500kg of coconut oil fatty acid (purchased from Shandong Boxing China Resources Oleochemical Co., Ltd.) into the reaction kettle, stir and heat to 105-110°C, and start to add 390kg of N,N-dimethylpropylenediamine dropwise , After adding the heat preservation reaction for 1.0h. Then, the pressure was 200Pa, the temperature was 140°C and the temperature was kept for 1.0h to obtain the intermediate cocamide.

[0034] Step 2: Add 222kg of epichlorohydrin into the reaction kettle, stir and heat to 40-45°C, start to add 324kg of anhydrous sodium bisulfite in batches, and keep warm for 3.0 hours to obtain the intermediate chlorohydroxypropyl sulfonic acid sodium.

[0035] Step 3: Add 667kg of intermediate cocoamide into the reaction kettle, heat to 60-65°C, add 113kg of sodium hydroxide, start to add 467kg of intermediate sodium chlorhydroxypropyl sulfonate in batches, and keep warm for 2.0 hours after adding. The target product cocamidopropyl-2-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com