Fluorine-containing polyether hydrophilic modifier, preparation method and water-dispersible polyisocyanates curing agent

A technology of hydrophilic modifier and polyisocyanate, which is applied in the field of water-dispersible polyisocyanate curing agent, can solve the problems of short pot life and achieve the effects of prolonging pot life and reducing the chance of contacting and reacting with water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of a fluorine-containing polyether hydrophilic modifier, which is used to make the fluorine-containing polyether hydrophilic modifier according to claim 1, and its specific steps include:

[0040]S1. Synthesis of tertiary amino polyether monoalcohol: use propylene oxide as a monomer and dialkylamine as an initiator, and synthesize a tertiary amino polyether with a hydroxyl group at one end and a tertiary amino group at the other end by anionic ring-opening polymerization Monohydric alcohol; wherein, propylene oxide is a monomer and the molar ratio of dialkylamine is 2:1~30:1, preferably 2:1~20:1, more preferably 5:1~10:1; step S1 The specific process is: S11, using dialkylamine as the initiator and metered propylene oxide in the autoclave for ring-opening polymerization reaction; when the autoclave is aged to normal pressure, reduce the temperature to obtain tertiary amino polyether Monohydric alcohol crude product. Wherein, the high-pressure react...

Embodiment 1

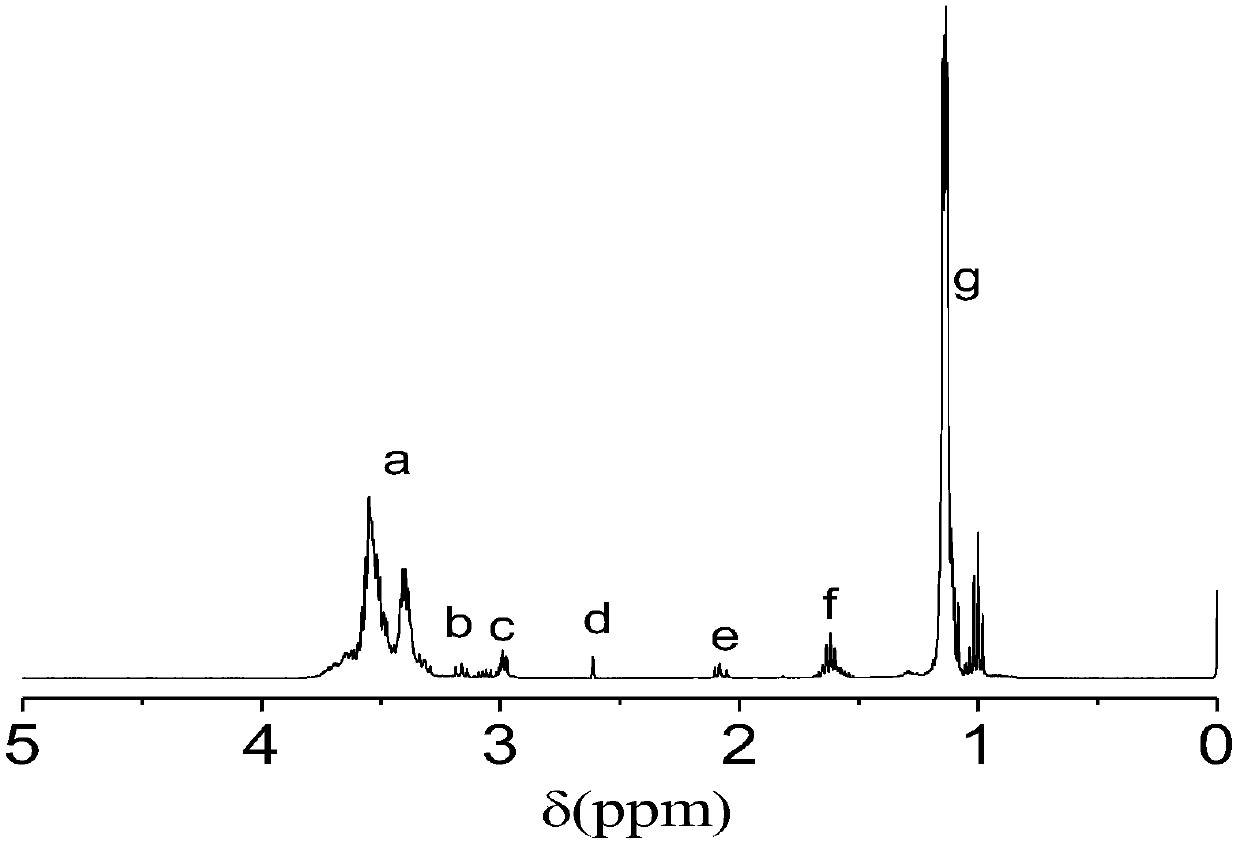

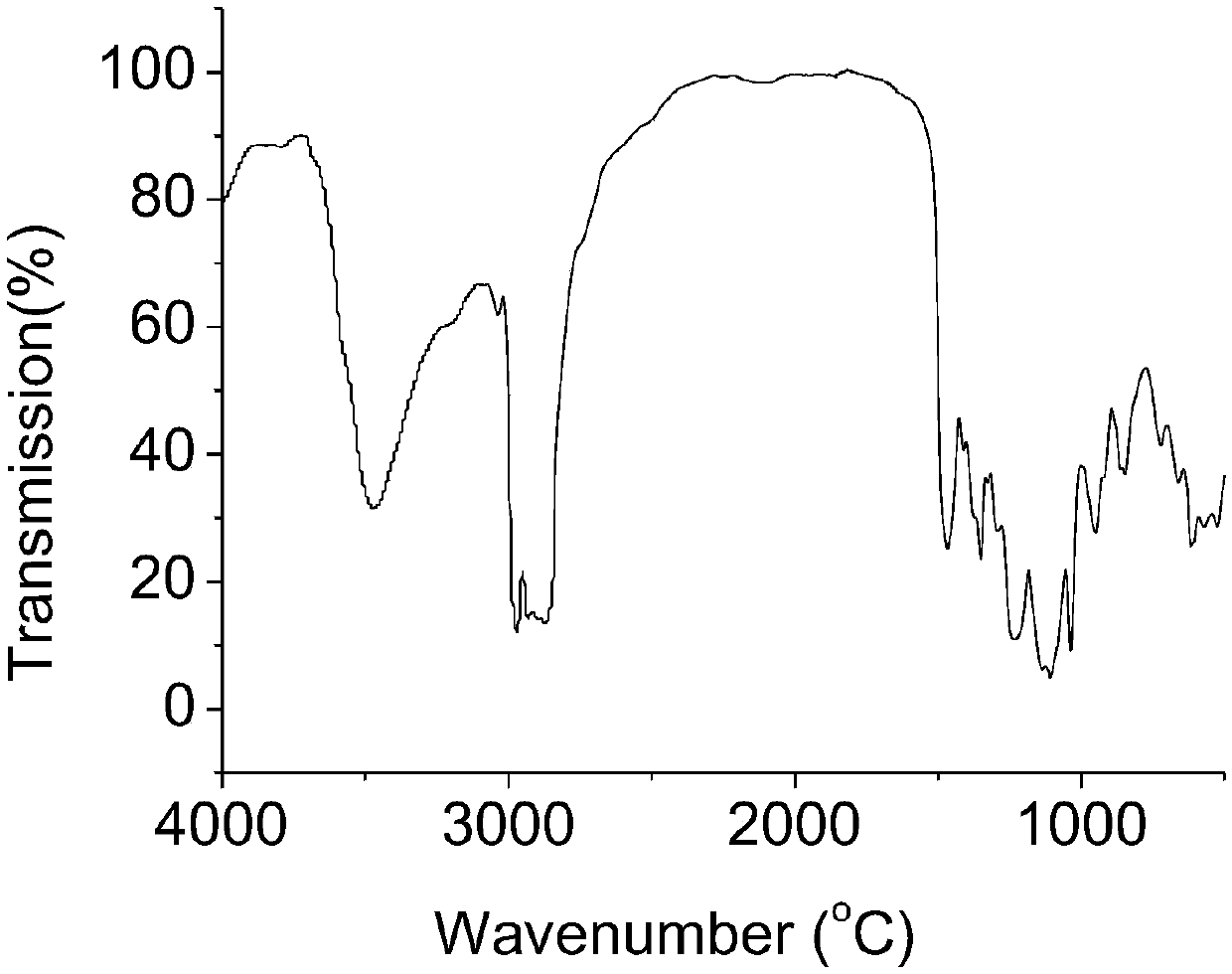

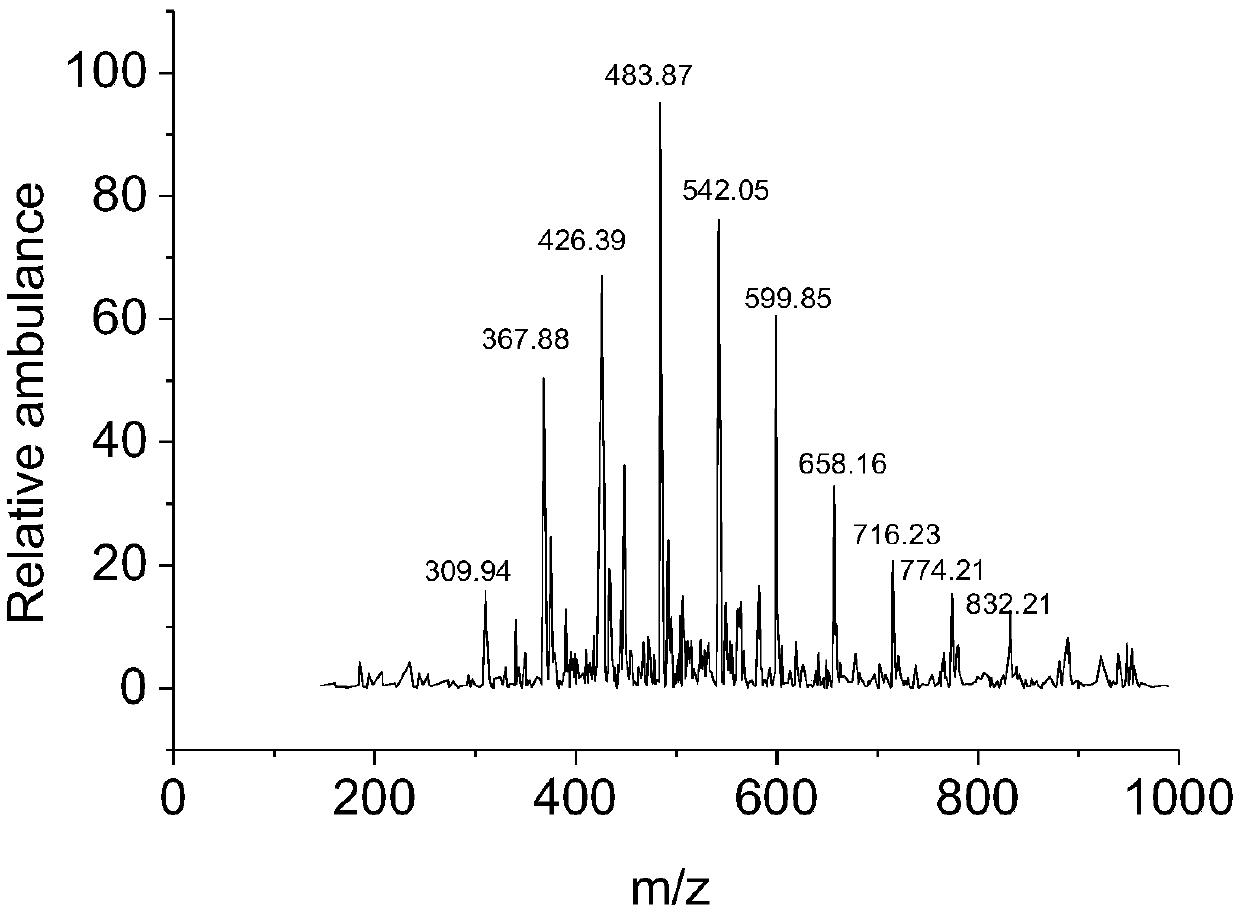

[0047] Such as Figure 1-4 As shown, diethylamine was used as an initiator and KOH was used as a catalyst to catalyze the ring-opening polymerization of propylene oxide. The synthesis was carried out in a clean and dry 1L stirred autoclave. First place 2.8g of KOH catalyst in the autoclave, and then repeatedly vacuumize and fill the autoclave with nitrogen. Then, 111.0 g (~1.52 eq) of chromatographically pure grade (purity ≥ 99.5%) diethylamine was added into the kettle at room temperature as a starting agent to synthesize monofunctional polyether. At room temperature, 3.6 bar nitrogen was introduced. Then, 40 g of propylene oxide was pressed in, and the temperature of the reactor was gradually raised to 125° C. for induction reaction. When the reaction pressure drops suddenly and the temperature rises more than 5 °C, it indicates that the induced reaction is over. 426 g of propylene oxide were gradually added to the autoclave over the next 3 hours and 30 minutes. The mix...

Embodiment 2

[0063] Such as Figure 5 As shown, using polyether A as a raw material, 85g of dry dichloromethane solvent, 40g of polyether A (as an initiator), 1.1g of tetrabutylammonium bromide, 1.2g of boron trifluoride ether (as a catalyst) Add it to a three-necked flask equipped with a stirrer and a thermometer, and start stirring. Use a refrigerator to lower the temperature of the reaction system to about 0°C. After stirring for 20-30 minutes, start to add 72g of 3-(2-perfluorohexylethoxy)-1,2-propylene oxide dropwise, and maintain the temperature of the reaction system at Around 0°C, the dropwise addition time is about 2 hours. After the dropwise addition, keep the temperature constant and continue the reaction for 3h. Then, 200 g of water was added and stirred for 5 min, thereby destroying the catalyst and terminating the polymerization reaction. The water-insoluble oil phase was removed, and then subjected to vacuum distillation to obtain a fluorine-containing polyether monohydri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com