Water dispersible polyisocyanate composition and preparation method thereof

A technology of polyisocyanate and diisocyanate, which is applied in the field of water-dispersible polyisocyanate composition and its preparation, can solve the problems of short pot life and high production cost, achieve short pot life, improve performance, and reduce the chance of releasing CO2 gas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of a water-dispersible polyisocyanate composition, used to prepare the water-dispersible polyisocyanate composition of any one of claims 1-8, which is prepared in this way:

[0032] S1. Synthesis of hydrophilic modified polyisocyanate curing agent: first synthesize fluorine-containing polyether hydrophilic modifier; then heat polyisocyanate to 70-100°C under nitrogen protection; then add fluorine-containing polyether hydrophilic The water modifier is reacted in the presence of the catalyst dibutyltin dilaurate, wherein the mass of the fluorine-containing polyether hydrophilic modifier is 5%-30% of the mass of the polyisocyanate, and the reaction temperature is 80-85 ℃, the reaction time is 2.5-3-4h; then add benzoyl chloride to terminate the reaction, the mass of benzoyl chloride is 0.01-0.1% of the total mass of reactants; stop the reaction to obtain a hydrophilic modified polyisocyanate curing agent.

[0033] In step S1, the synthesis process of t...

Embodiment 1

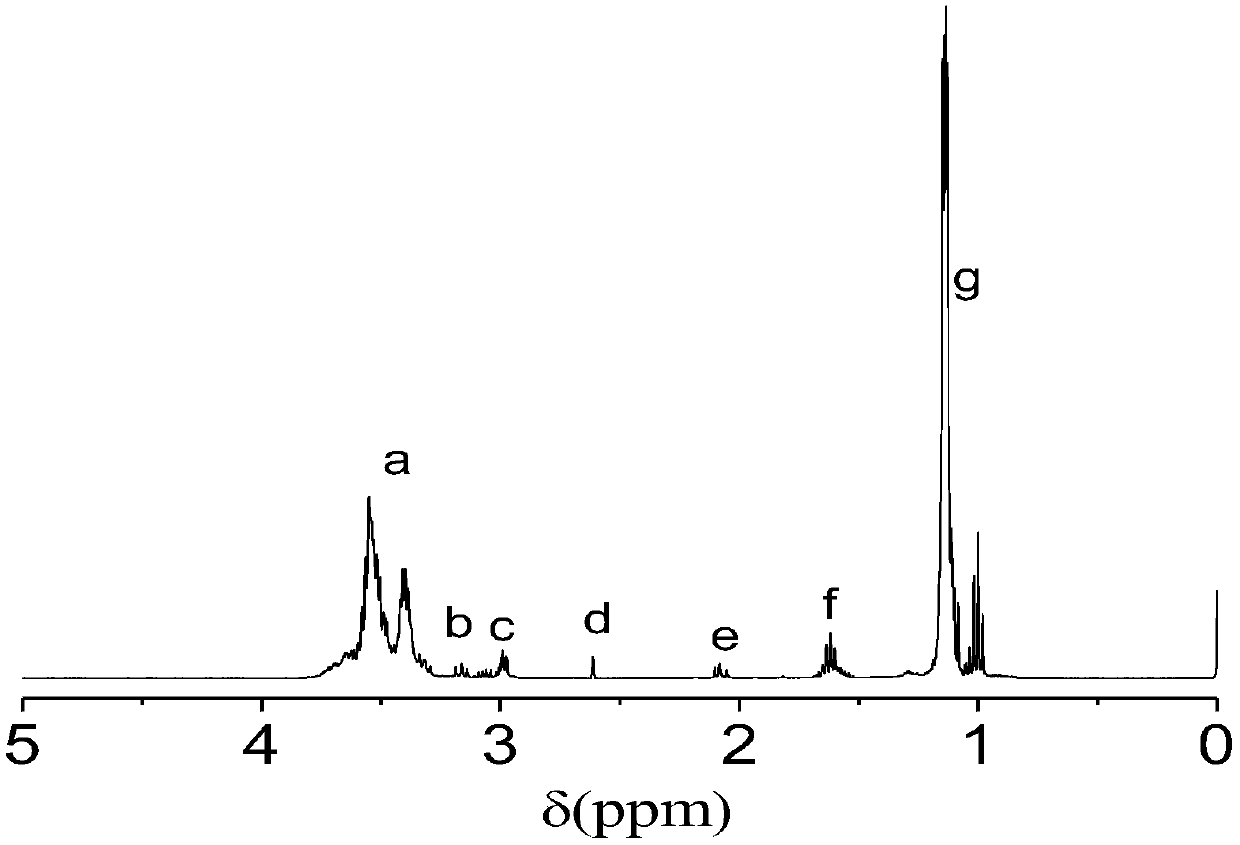

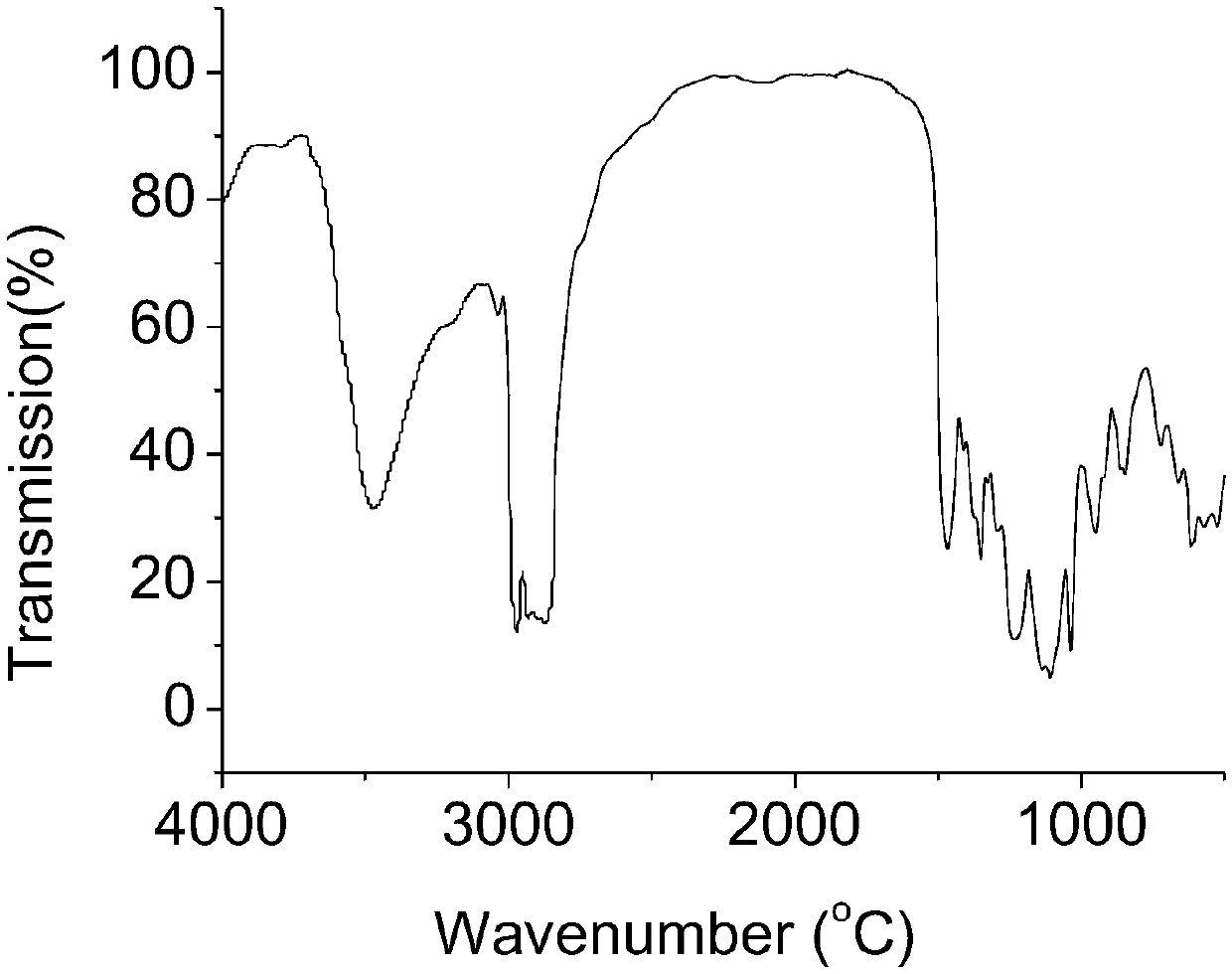

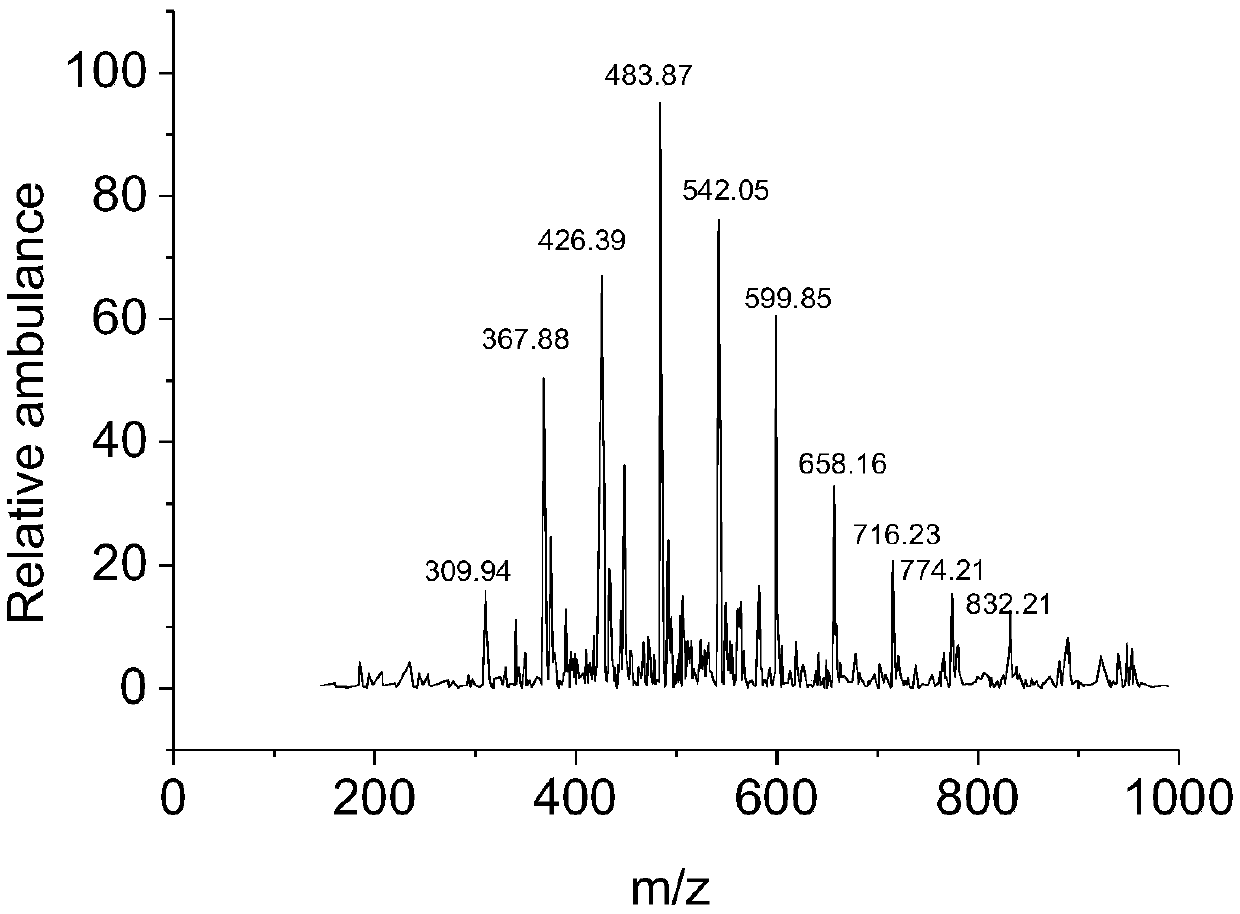

[0041] Such as Figure 1-4 As shown, diethylamine was used as an initiator and KOH was used as a catalyst to catalyze the ring-opening polymerization of propylene oxide. The synthesis was carried out in a clean and dry 1L stirred autoclave. First place 2.8g of KOH catalyst in the autoclave, and then repeatedly vacuumize and fill the autoclave with nitrogen. Then, 111.0 g (~1.52 eq) of chromatographically pure grade (purity ≥ 99.5%) diethylamine was added into the kettle at room temperature as a starting agent to synthesize monofunctional polyether. At room temperature, 3.6 bar nitrogen was introduced. Then, 40 g of propylene oxide was pressed in, and the temperature of the reactor was gradually raised to 125° C. for induction reaction. When the reaction pressure drops suddenly and the temperature rises more than 5 °C, it indicates that the induced reaction is over. 426 g of propylene oxide were gradually added to the autoclave over the next 3 hours and 30 minutes. The mix...

Embodiment 2

[0057] Such as Figure 5 As shown, using polyether A as a raw material, 85g of dry dichloromethane solvent, 40g of polyether A (as an initiator), 1.1g of tetrabutylammonium bromide, 1.2g of boron trifluoride ether (as a catalyst) Add it to a three-necked flask equipped with a stirrer and a thermometer, and start stirring. Use a refrigerator to lower the temperature of the reaction system to about 0°C. After stirring for 20-30 minutes, start to add 72g of 3-(2-perfluorohexylethoxy)-1,2-propylene oxide dropwise, and maintain the temperature of the reaction system at Around 0°C, the dropwise addition time is about 2 hours. After the dropwise addition, keep the temperature constant and continue the reaction for 3h. Then, 200 g of water was added and stirred for 5 min, thereby destroying the catalyst and terminating the polymerization reaction. The water-insoluble oil phase was removed, and then subjected to vacuum distillation to obtain a fluorine-containing polyether monohydri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com