Imidazole latent curing agent containing triazinetrione ring structure and preparation method thereof

A technology of latent curing agent and triazinetrione ring, which is applied in the field of epoxy resin latent curing agent and its preparation, can solve the problems of poor compatibility, short pot life at room temperature, limited application, etc., and achieve good compatibility , Long storage period, overcome the effect of short application period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

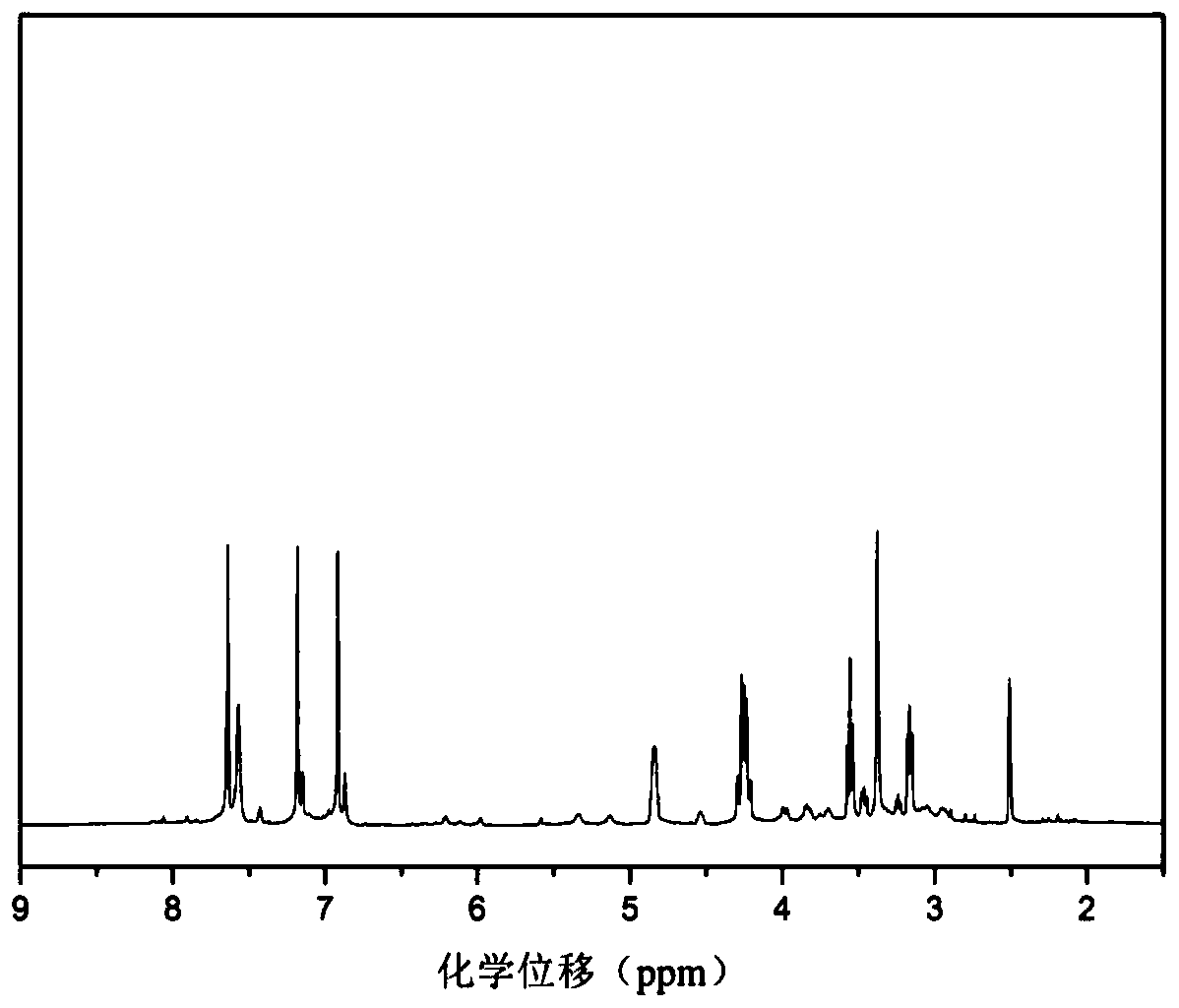

Embodiment 1

[0031] The imidazole latent curing agent containing triazinetrione ring structure has the following molecular structural formula:

[0032] Among them, R 1 and R 2 Both are hydrogen.

[0033] The preparation method of the above-mentioned imidazole latent curing agent containing triazinetrione ring structure, the specific steps are as follows:

[0034] Mix 20.4g of imidazole and 300ml of N,N-dimethylformamide in the reaction flask evenly, and then gradually add 29.7g of triglycidyl isocyanurate to the reaction flask under stirring at 90°C; triglycidyl isocyanurate After the glyceride was added, the reaction was stirred at 110° C. for 4 hours; after the reaction, the solvent was removed by rotary evaporation to obtain an imidazole latent curing agent (code: A) containing a triazinetrione ring structure.

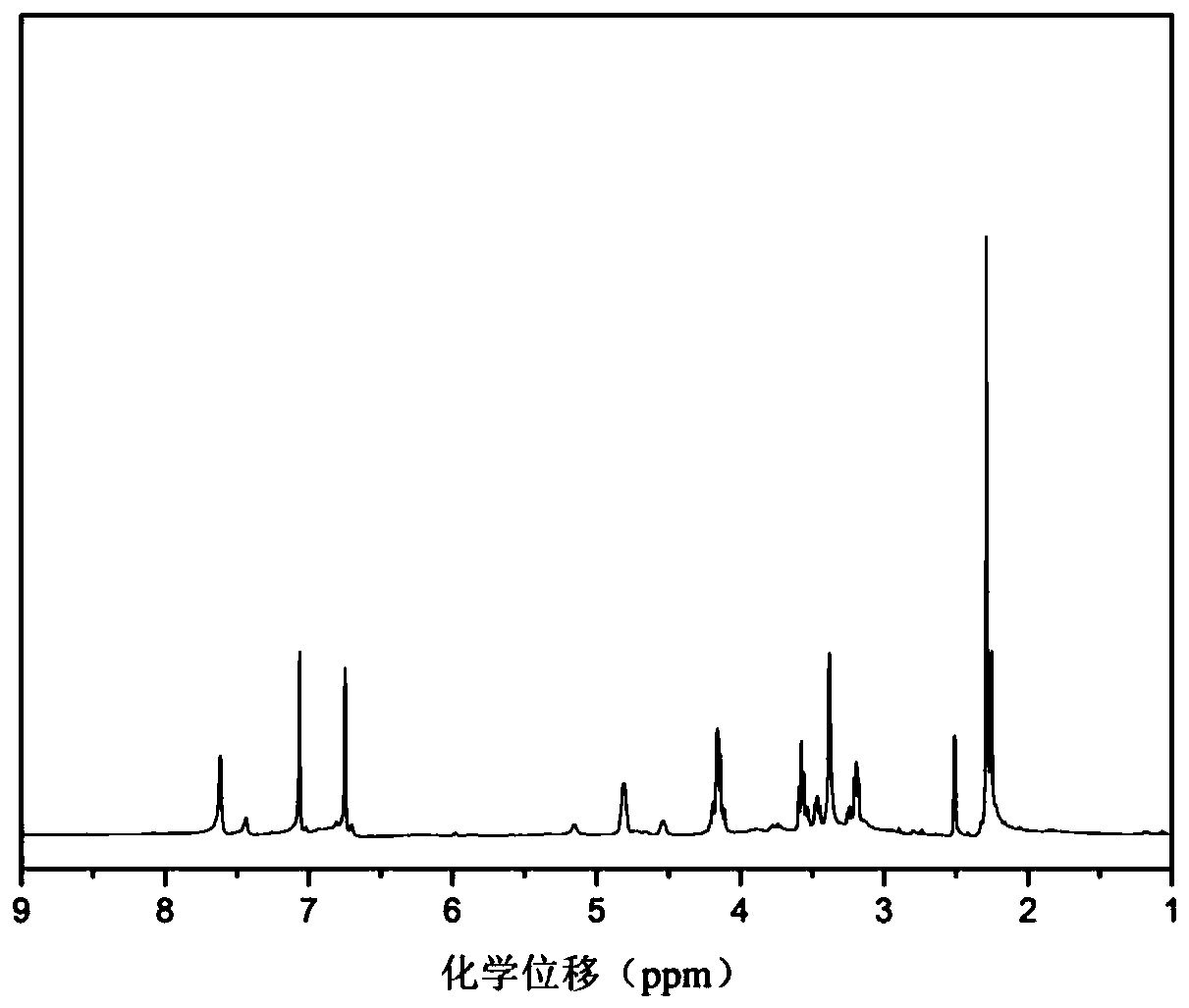

Embodiment 2

[0036] The imidazole latent curing agent containing triazinetrione ring structure has the following molecular structural formula:

[0037] Among them, R 1 for methyl and R 2 for hydrogen.

[0038] The preparation method of the above-mentioned imidazole latent curing agent containing triazinetrione ring structure, concrete steps are as follows: 24.6g2-methylimidazole and 300mlN,N-dimethylformamide are mixed in reaction bottle, then in 120 29.7g of triglycidyl isocyanurate was gradually added to the reaction flask under the condition of stirring; after the addition of TGIC, the reaction was stirred at 130°C for 5h; after the reaction, the solvent was removed by rotary evaporation to obtain Ring structure imidazole latent curing agent (code: B).

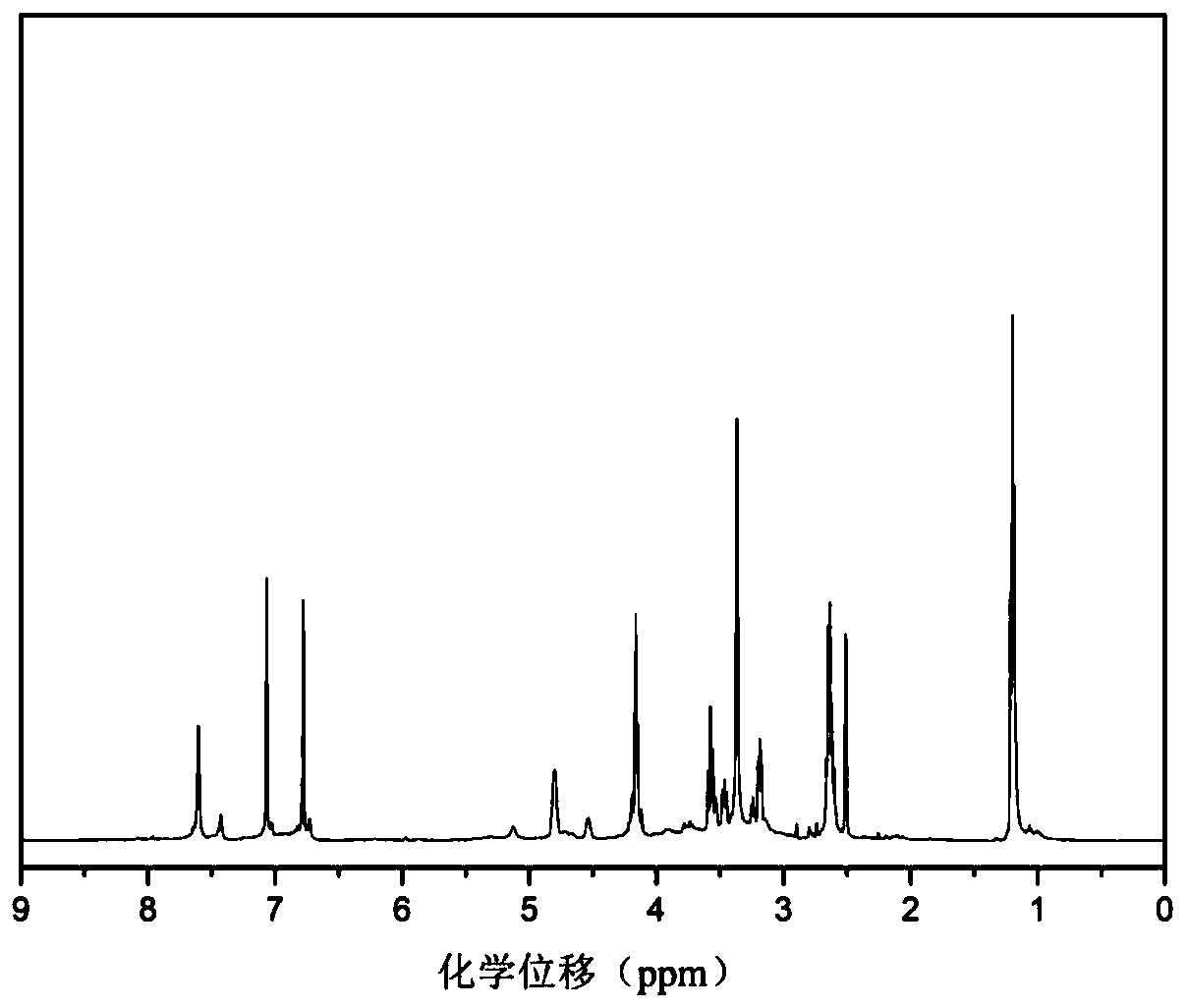

Embodiment 3

[0040] The imidazole latent curing agent containing triazinetrione ring structure has the following molecular structural formula:

[0041] Among them, R 1 for ethyl and R 2 for hydrogen.

[0042] The preparation method of the above-mentioned imidazole latent curing agent containing triazinetrione ring structure, concrete steps are as follows: 28.8g2-ethylimidazole and 300mlN,N-dimethylformamide are mixed in reaction bottle, then in 130 29.7g of triglycidyl isocyanurate was gradually added to the reaction flask under stirring conditions; after TGIC was added, stirred and reacted at 140°C for 5h; after the reaction, the solvent was removed by rotary evaporation to obtain Ring structure imidazole latent curing agent (code: C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com