Aqueous anti-rusting paint and preparation method therefor

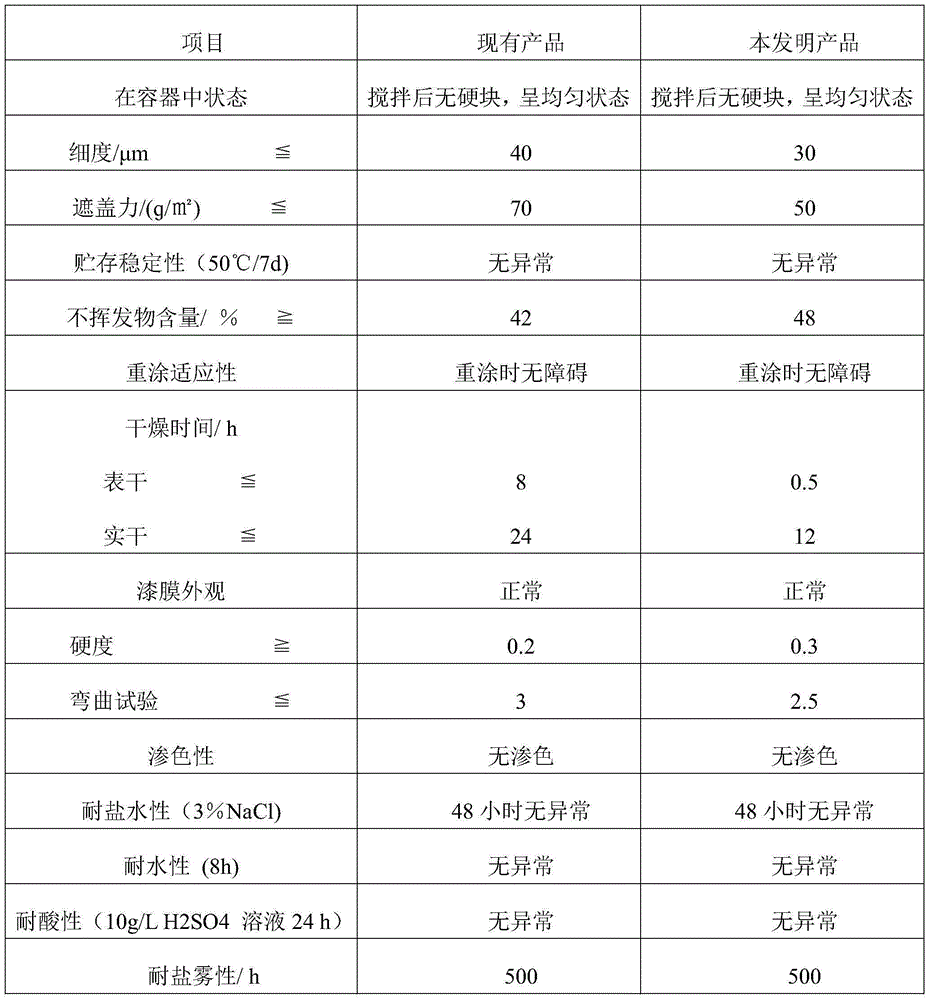

A water-based anti-rust paint and modification technology, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve problems such as complex construction processes, and achieve good thermal stability, good weather resistance, and good hard water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] A water-based antirust paint of the present invention, taking blue as an example, it includes the following raw materials in parts by mass: 650 parts of acrylic modified alkyd resin emulsion, 113 parts of deionized water, 100 parts of pigment and filler, 9 parts of rheological agent 1 part, 4 parts of dispersant, 2 parts of wetting agent, 3 parts of defoamer, 1 part of bactericide, 80 parts of film-forming aid, 20 parts of co-solvent, 5 parts of flash rust agent, 6 parts of multi-functional additive, thickener 6 parts of drug solution.

[0019] The above-mentioned pigments and fillers include 20 parts of R501 titanium dioxide, 10 parts of phthalocyanine blue pigment, 20 parts of precipitated barium sulfate, and 50 parts of aluminum tripolyphosphate;

example 2

[0021] A water-based antirust paint of the present invention, taking yellow as an example, it includes the following raw materials in parts by mass: 650 parts of acrylic modified alkyd resin emulsion, 115 parts of deionized water, 100 parts of pigment and filler, and 9 parts of rheological agent , 4 parts of dispersant, 2 parts of wetting agent, 3 parts of defoamer, 1 part of bactericide, 80 parts of film-forming aid, 20 parts of co-solvent, 5 parts of flash rust agent, 6 parts of multi-functional additive, thickener 4 parts of the solution.

[0022] The above-mentioned pigments and fillers include 20 parts of R501 titanium dioxide, 60 parts of medium chrome yellow powder, and 20 parts of aluminum tripolyphosphate;

example 3

[0024] A water-based antirust paint of the present invention, taking gray as an example, it includes the following raw materials in parts by mass: 650 parts of acrylic modified alkyd resin emulsion, 115 parts of deionized water, 100 parts of pigment and filler, and 9 parts of rheological agent , 4 parts of dispersant, 2 parts of wetting agent, 3 parts of defoamer, 1 part of bactericide, 80 parts of film-forming aid, 20 parts of co-solvent, 5 parts of flash rust agent, 6 parts of multi-functional additive, thickener 8 parts of the solution.

[0025] The above-mentioned pigments and fillers include 25 parts of R501 titanium dioxide, 15 parts of iron black powder, 20 parts of aluminum tripolyphosphate, and 40 parts of precipitated barium sulfate;

[0026] Preferably, the mass-number ratio of thickener to water in the thickener solution is 1:1.

[0027] The preparation process steps of water-based antirust paint are as follows:

[0028] (1) First, add rheological agent, FA365 di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com