Phosphate-free detergent and production method thereof

A production method and technology for washing powder, which are applied in the field of daily chemical industry, can solve the problems of high cost of phosphorus-free washing powder, slow magnesium ion exchange rate, low magnesium ion efficiency, etc. Fast dissolving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Take 160 parts of sodium dodecylbenzenesulfonate, 200 parts of light sodium carbonate, 100 parts of anhydrous sodium metasilicate, 20 parts of disodium edetate, 2 parts of fluorescent whitening agent, and Put 157 parts of starch powder in a ribbon mixer and mix and stir for 2-3 minutes to obtain semi-finished product A1.

[0014] (2) Take another 330 parts of fatty alcohol polyoxyethylene ether AEO-330 and 940 parts of fatty alcohol polyoxyethylene ether AEO-940 and heat it to a molten state, add 1 portion of lemon essence into the molten substance, and stir evenly to obtain a mixture B1 .

[0015] (3) Under the condition of stirring, add 40 parts of acrylic acid-maleic acid copolymer sodium salt, 250 parts of alkyl modified dicarboxylate polymer and mixture B1 to the semi-finished product A1, and stir until all the liquid ingredients All of them are absorbed into dry powder and granules, and this washing powder is obtained.

Embodiment 2

[0017] (1) Take 150 parts of sodium dodecylbenzenesulfonate, 210 parts of light sodium carbonate, 110 parts of anhydrous sodium metasilicate, 25 parts of disodium edetate, 3 parts of fluorescent whitening agent, and 165 parts of starch powder were placed in a ribbon mixer and mixed for 2-3 minutes to obtain semi-finished product A2.

[0018] (2) Take another fatty alcohol polyoxyethylene ether AEO-325 parts and fatty alcohol polyoxyethylene ether AEO-935 parts and heat it to a molten state, add 2 parts of lemon essence into the molten substance, and stir evenly to obtain a mixture B2 .

[0019] (3) Add 35 parts of acrylic acid-maleic acid copolymer sodium salt, 240 parts of alkyl-modified dicarboxylate polymer and mixture B2 to the semi-finished product A2 under stirring conditions, and stir until all liquid components All of them are absorbed into dry powder and granules, and this washing powder is obtained.

Embodiment 3

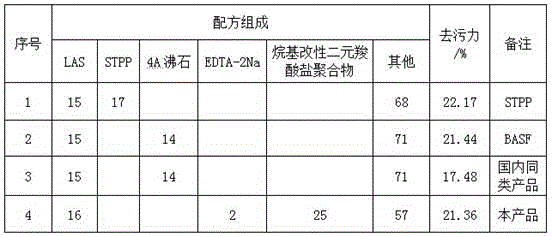

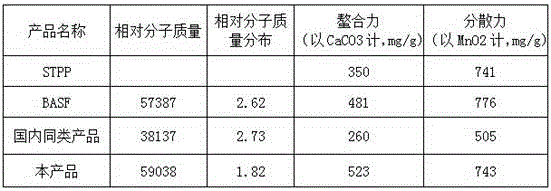

[0021] The present invention replaces STPP and 4A zeolite with the comparison of the decontamination ability of similar products at home and abroad, taking the standard washing powder as the benchmark, and the decontamination effect is shown in Table 1.

[0022]

[0023] Table 1

[0024] As shown in the experimental results in Table 1, after the present invention cancels the 4A zeolite system, the decontamination ability of the new phosphorus substitute additive has a very good performance. The decontamination ability remained basically the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com