Cleaning agent for washing machine slot

A washing machine tank and cleaning agent technology, applied in the field of cleaning agents, can solve the problem that the detergency ability needs to be improved, and achieve the effects of avoiding secondary pollution, good synergy and strong detergency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

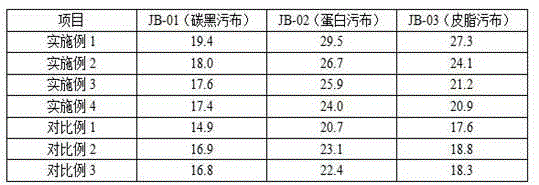

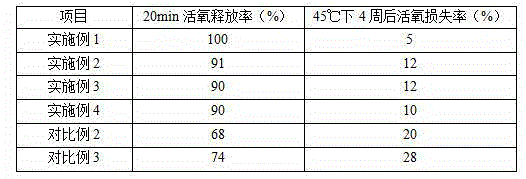

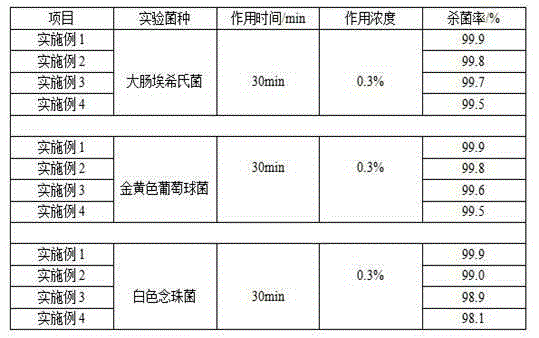

Examples

Embodiment 1

[0024] Embodiment 1, washing machine tank cleaner of the present invention

[0025] Formula: sodium carbonate 620g, sodium percarbonate 250g, tetraacetylethylenediamine 20g, binary compound enzyme 2g (the weight ratio of lipase and protease is 1:2), α-alkenyl sulfonate 8g, calcium carbonate 50g, Sodium silicate 50g.

[0026] Preparation: Mix sodium carbonate, sodium percarbonate, tetraacetylethylenediamine, binary compound enzyme, α-alkenyl sulfonate, calcium carbonate and sodium silicate and stir evenly.

Embodiment 2

[0027] Embodiment 2, washing machine tank cleaner of the present invention

[0028] Formula: 620g sodium carbonate, 250g sodium percarbonate, 20g tetraacetylethylenediamine, 2g binary compound enzyme (the weight ratio of lipase and protease is 1:2), 8g linear alkylbenzene sulfonate, 50g calcium carbonate , Sodium silicate 50g.

[0029] Preparation: Mix sodium carbonate, sodium percarbonate, tetraacetylethylenediamine, binary compound enzyme, linear alkylbenzene sulfonate, calcium carbonate and sodium silicate and stir evenly.

Embodiment 3

[0030] Embodiment 3, washing machine tank cleaner of the present invention

[0031] Formula: 550g of sodium carbonate, 300g of sodium percarbonate, 60g of tetraacetylethylenediamine, 5g of binary compound enzyme (the weight ratio of lipase and protease is 1:2), 15g of α-alkenyl sulfonate, 20g of calcium carbonate, Sodium silicate 50g.

[0032] Preparation: Mix sodium carbonate, sodium percarbonate, tetraacetylethylenediamine, binary compound enzyme, α-alkenyl sulfonate, calcium carbonate and sodium silicate and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com