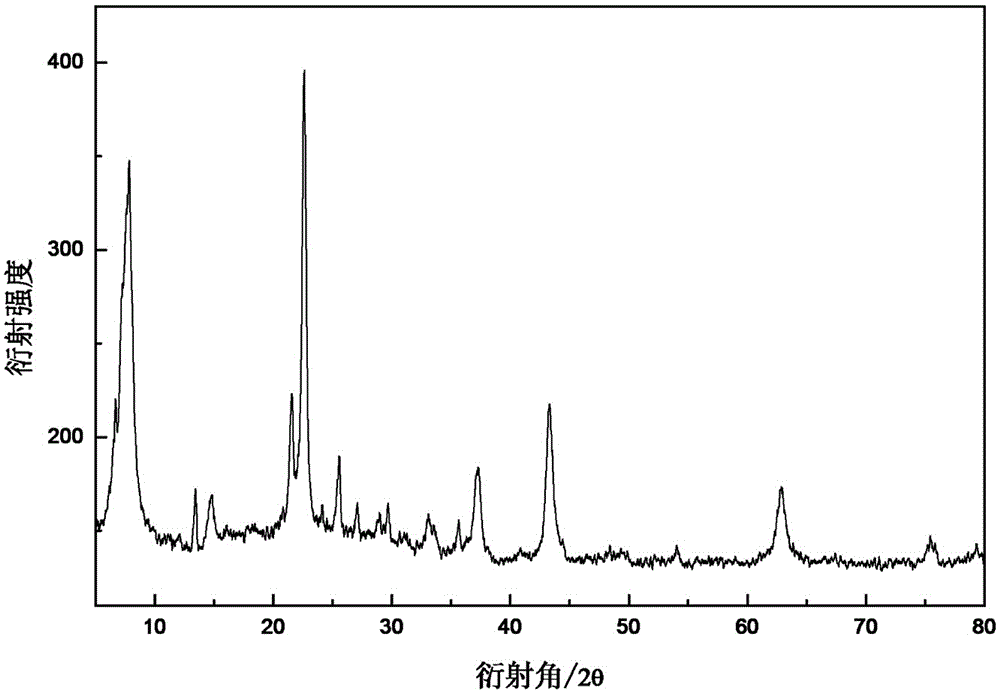

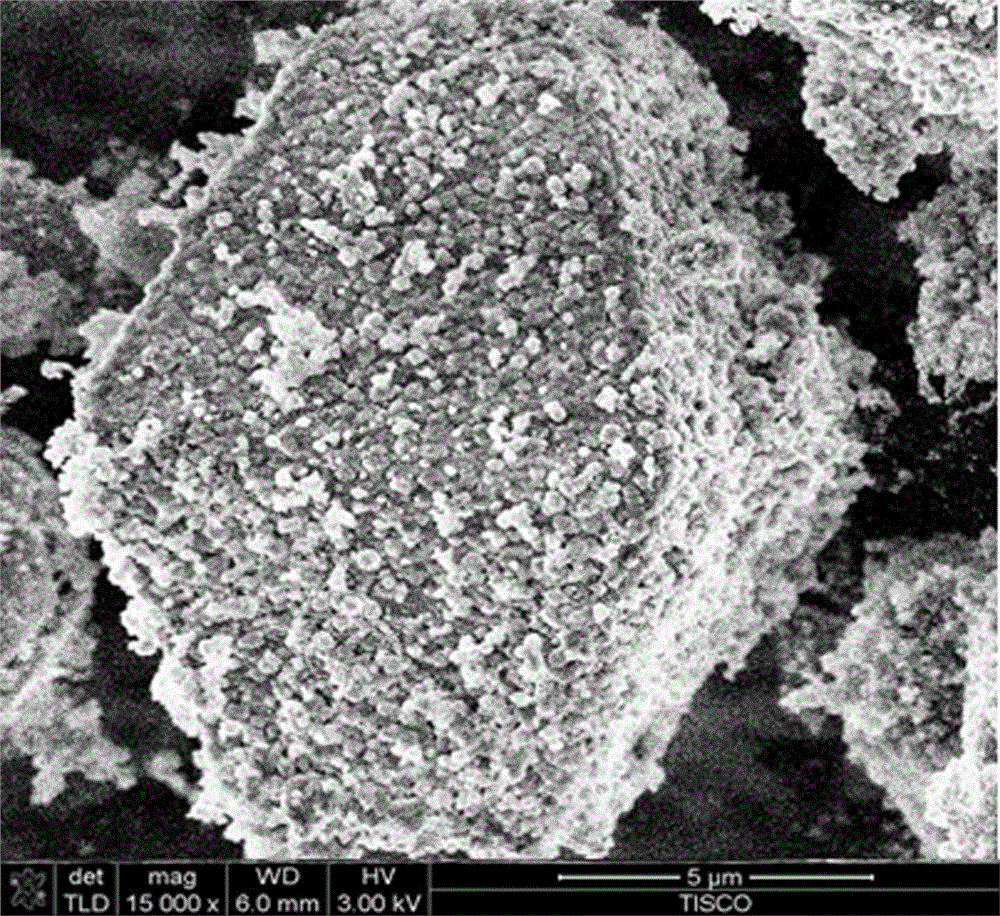

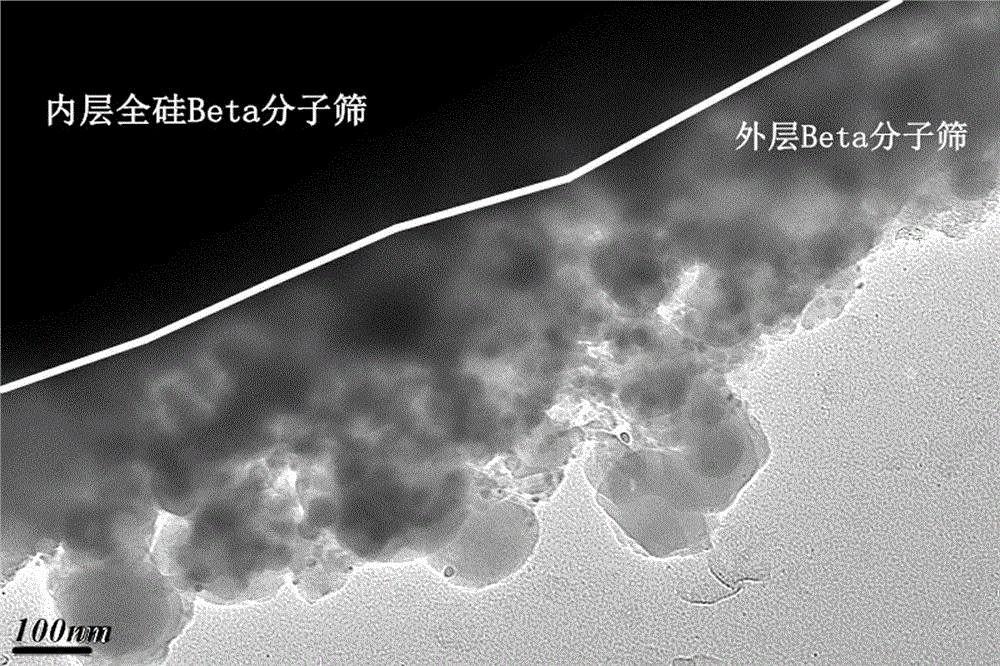

Core-shell structured Beta molecular sieve and preparation method thereof

A core-shell structure and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as weak ethanol conversion ability, limited catalytic performance, poor selectivity, etc., to achieve efficient utilization and high ethanol Conversion, hydrogen selectivity, and effect of selectivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take 2 mL of deionized water, 37.2 mL of tetraethylammonium hydroxide, and 21.95 mL of silica sol into a polytetrafluoroethylene container, heat to 40°C and stir for 3 hours to form a transparent mixed solution, and add hydrogen dropwise at a rate of 0.1 mL / min Fluoric acid 2.88mL, stirred for 1h, formed a white colloidal mixed solution.

[0030] Put the polytetrafluoroethylene container containing the white colloidal mixed solution into a stainless steel reaction kettle, seal it, place it in a constant temperature box, and heat it to 140°C for static crystallization for 168 hours; take out the reaction kettle and place it in a quenching tank at 10°C The deionized water was rapidly cooled to 20°C; the crystallized gel solution was centrifuged at 8000r / min for 20min, the solid precipitate was retained, placed in a vacuum drying oven, and dried at 100°C for 12h to obtain a white solid product.

[0031] Put the vacuum-dried white solid product in a roasting furnace and roa...

Embodiment 2

[0046] Take 2 mL of deionized water, 37.2 mL of tetraethylammonium hydroxide, and 21.95 mL of silica sol into a polytetrafluoroethylene container, heat to 40°C and stir for 3 hours to form a transparent mixed solution, and add hydrogen dropwise at a rate of 0.1 mL / min Fluoric acid 2.88mL, stirred for 1h, formed a white colloidal mixed solution.

[0047] Put the polytetrafluoroethylene container containing the white colloidal mixed solution into a stainless steel reaction kettle, seal it, place it in a constant temperature box, and heat it to 140°C for static crystallization for 168 hours; take out the reaction kettle and place it in a quenching tank at 10°C The deionized water was rapidly cooled to 20°C; the crystallized gel solution was centrifuged at 8000r / min for 20min, the solid precipitate was retained, placed in a vacuum drying oven, and dried at 100°C for 12h to obtain a white solid.

[0048] Put the vacuum-dried white solid product in a roasting furnace and roast at 55...

Embodiment 3

[0060] Take 3.1mL of deionized water, 40.2mL of tetraethylammonium hydroxide, and 23.3mL of silica sol into a polytetrafluoroethylene container, heat to 40°C and stir for 3 hours to form a transparent mixed solution, and add dropwise at a rate of 0.1mL / min Hydrofluoric acid 2.88mL, stirred for 1h, formed a white colloidal mixed solution.

[0061] Put the polytetrafluoroethylene container containing the white colloidal mixed solution into a stainless steel reaction kettle, seal it, place it in a constant temperature box and heat it to 160°C, and statically crystallize it for 200h; take out the reaction kettle and place it in a quenching tank at 10°C The deionized water was rapidly cooled to 20°C; the crystallized gel solution was centrifuged at 8000r / min for 20min, the solid precipitate was retained, placed in a vacuum drying oven, and dried at 100°C for 12h to obtain a white solid.

[0062] The vacuum-dried white solid product was placed in a roasting furnace, and roasted at 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com