Functionalized carbon nanotube loaded palladium nano-catalyst and preparation and application thereof

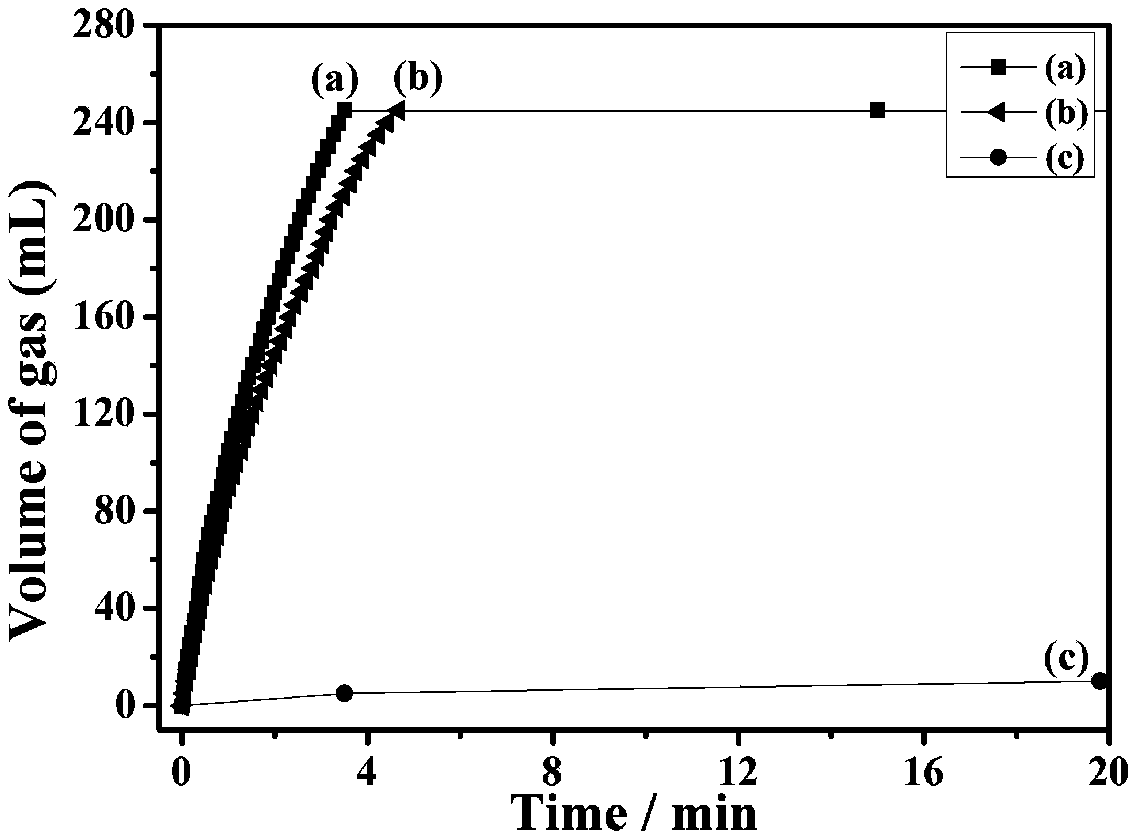

A carbon nanotube and catalyst technology, which is applied in the field of preparation of palladium nanocatalysts, can solve problems such as catalyst poisoning and deactivation, and achieve the effects of suppressing agglomeration, easy operation and good hydrogen selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. a preparation method of functionalized carbon nanotube supported palladium nano-catalyst, specifically comprising the following steps:

[0028] Add 0.1mmol of Na 2 PdCl 4 Dissolve in APTS+CNTS aqueous solution, stir evenly; 100mg of NaBH 4 Dissolve in 1 mL of distilled water, add the solution to the above mixed solution at 25°C, stir evenly with magnetic force, and stir until completely reduced; centrifuge and wash with water to prepare the Pd / F-CNTS catalyst.

[0029] 2. Sample testing

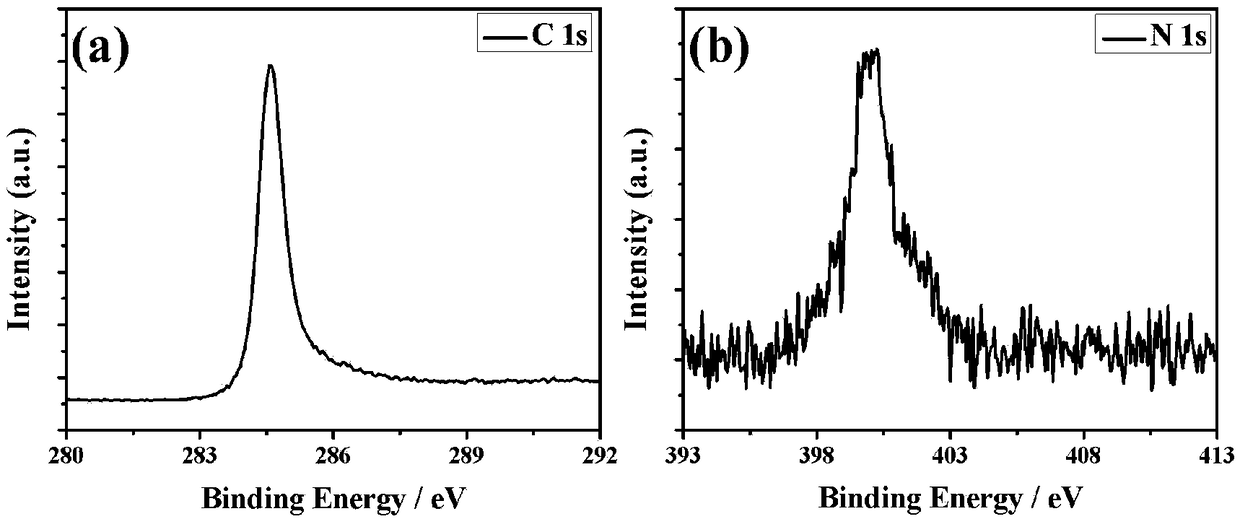

[0030] (1) vacuum-drying the Pd / F-CNTS catalyst prepared above; figure 2 , X-ray photoelectron spectroscopy (XPS) results showed that this method successfully synthesized Pd / F-CNTS, and the value of N / C on the surface of the sample was 14.43%;

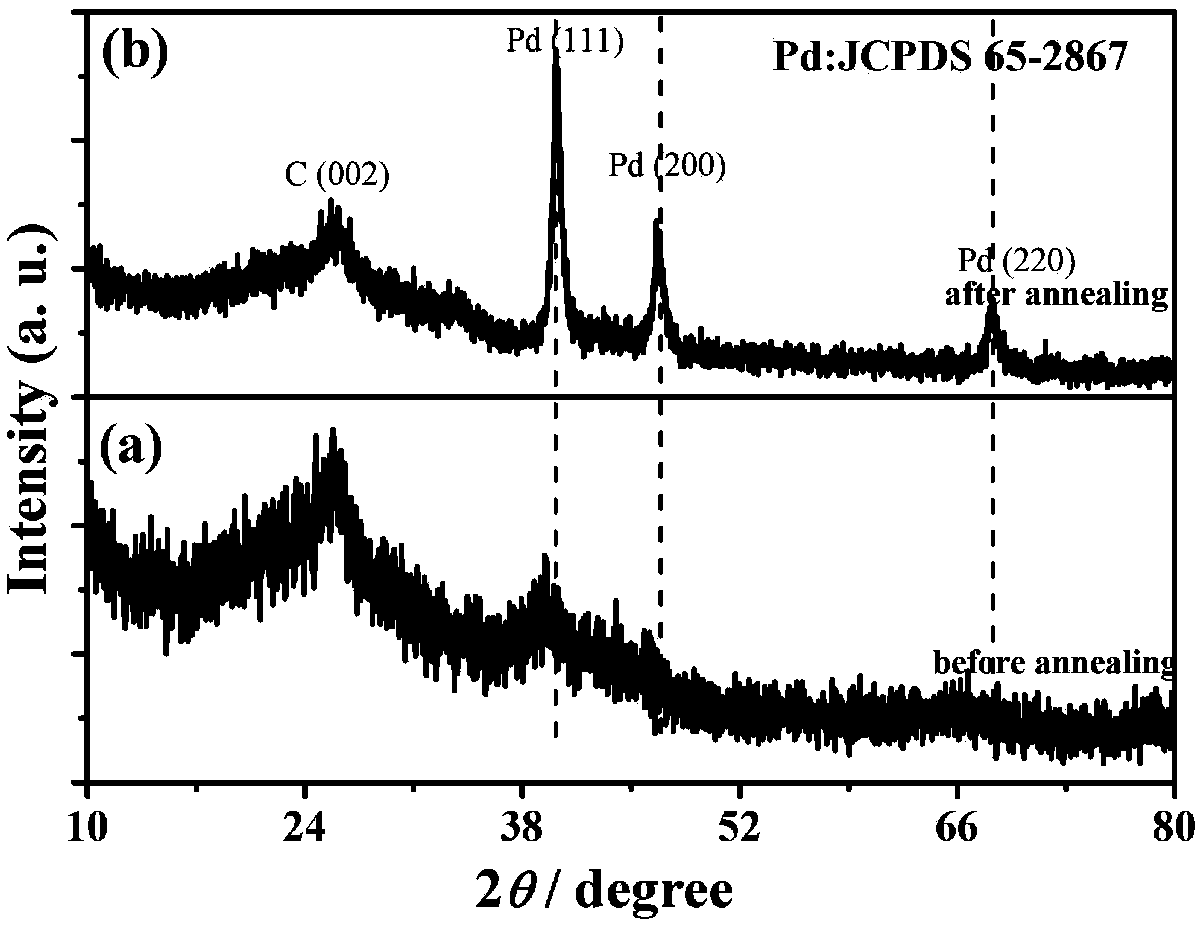

[0031] (2) The Pd / F-CNTS catalyst prepared above was vacuum-dried and annealed for 3 h at 873 K in an Ar atmosphere. refer to figure 1 , X-ray powder diffraction (XRD) results showed that this experimental method successfully synthesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com