Catalyst for preparing methyl glycolate through hydrogenation of dimethyl oxalate and synthesis method and application of catalyst

A technology of dimethyl oxalate and methyl glycolate, which is applied in the preparation of carboxylate, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problem that the preparation cost of silver-based catalysts is high, which is unsuitable for industrial device application and the price of catalysts. Expensive, stability is yet to be investigated and other issues, to achieve the effect of improving activity and stability, high selectivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

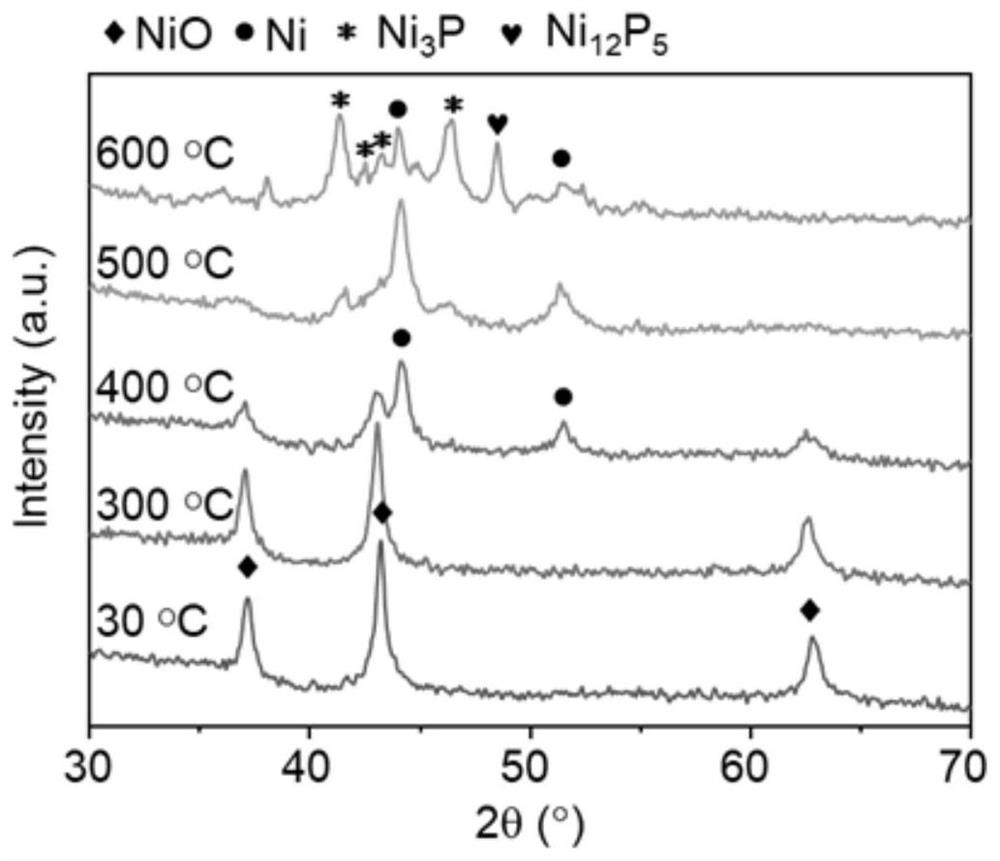

[0049] Weigh 7.6g of nickel nitrate hexahydrate and dissolve it in 75mL of deionized water, then take 10.0g of aluminum sesquioxide and put it in the above solution, add dropwise with 0.3mol / L sodium carbonate solution until the pH of the above solution is 12, at 80°C Stir for 5 hours, filter and wash with deionized water until the pH of the filtrate is about 7, dry at 100°C for 5 hours, and roast at 500°C for 5 hours. Weigh 2.0 g of sodium dihydrogen phosphate and dissolve it in 12 mL of deionized water, soak and age the calcined sample at room temperature for 24 h, dry at 100°C for 5 h, and calcinate at 500°C for 5 h to obtain the catalyst.

[0050] The above-mentioned catalyst is packed in a continuous fixed-bed reactor for reduction and activation treatment. The reduction temperature rises from room temperature to 600°C at 2°C / min, the reduction pressure is 0.2MPa, and the hydrogen volume space velocity is 150h -1 , the reduction time is 6h. The temperature is lowered to...

Embodiment 2

[0052] Weigh 7.6g of nickel nitrate hexahydrate and dissolve it in 75mL of deionized water, then take 10.0g of activated carbon and place it in the above solution, add dropwise 0.3mol / L sodium carbonate solution until the pH of the above solution is 12, stir at 80°C for 5h, After filtering, wash with deionized water until the pH of the filtrate is about 7, dry at 100°C for 5 hours, and roast at 500°C for 5 hours. Weigh 2.0 g of sodium dihydrogen phosphate and dissolve it in 12 mL of deionized water, soak and age the calcined sample at room temperature for 24 h, dry at 100°C for 5 h, and calcinate at 500°C for 5 h to obtain the catalyst.

[0053]The above-mentioned catalyst is packed in a continuous fixed-bed reactor for reduction and activation treatment. The reduction temperature rises from room temperature to 600°C at 2°C / min, the reduction pressure is 0.2MPa, and the hydrogen volume space velocity is 150h -1 , the reduction time is 6h. The temperature is lowered to 200°C,...

Embodiment 3

[0055] Weigh 7.6g of nickel nitrate hexahydrate and dissolve it in 75mL of deionized water, then take 10.0g of silicon dioxide and place it in the above solution, add dropwise 0.3mol / L sodium carbonate solution until the pH of the above solution is 12, and stir at 80°C After filtering for 5 hours, wash with deionized water until the pH of the filtrate is about 7, dry at 100°C for 5 hours, and roast at 500°C for 5 hours. Weigh 2.0 g of sodium dihydrogen phosphate and dissolve it in 12 mL of deionized water, soak and age the calcined sample at room temperature for 24 h, dry at 100°C for 5 h, and calcinate at 500°C for 5 h to obtain the catalyst.

[0056] The above-mentioned catalyst is packed in a continuous fixed-bed reactor for reduction and activation treatment. The reduction temperature rises from room temperature to 600°C at 2°C / min, the reduction pressure is 0.2MPa, and the hydrogen volume space velocity is 150h -1 , the reduction time is 6h. The temperature is lowered t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com