Hydrogen production device through reforming methane by using collaborative drive rotation sliding arc discharge plasma

A technology of discharge plasma and hydrogen production device, which is applied in the directions of hydrogen, inorganic chemistry, non-metallic elements, etc., can solve the problems of short residence time of reactants, limited treatment effect, elongated arc and arc, etc., and achieves reduced energy consumption and simple device. , the effect of high hydrogen selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Referring to the accompanying drawings, the present invention will be described in detail below.

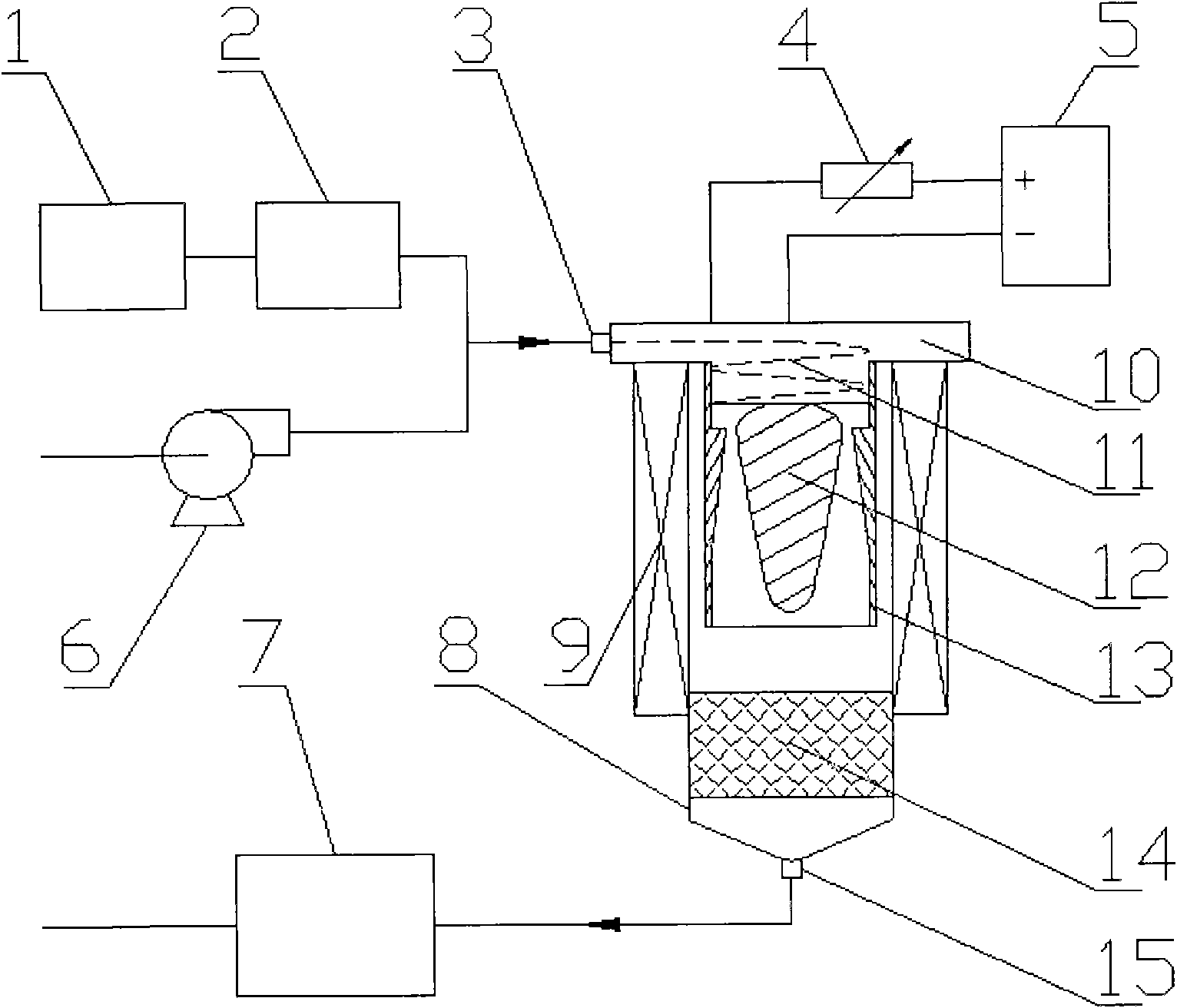

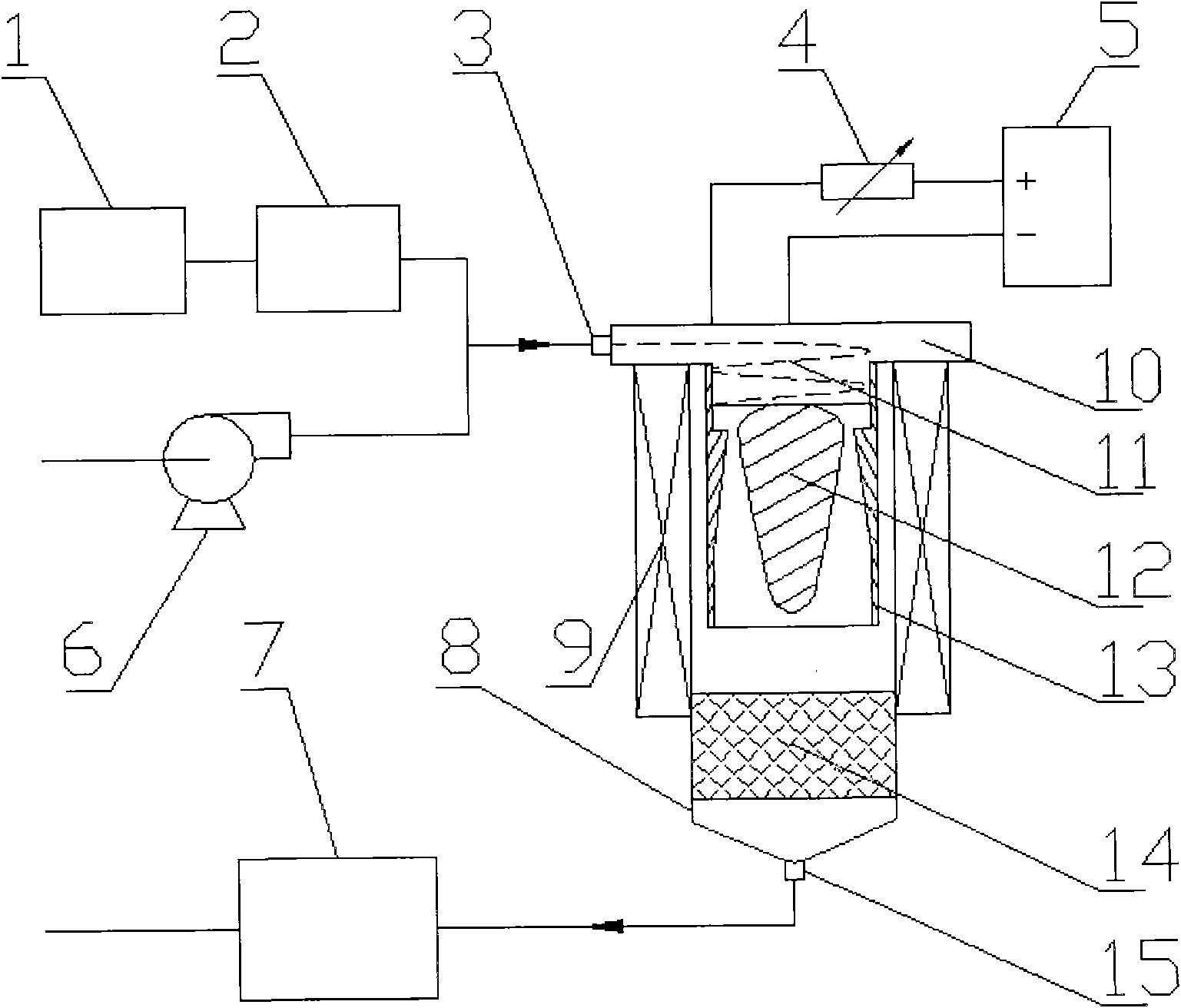

[0023] The synergistically driven rotary sliding arc discharge plasma reforming methane hydrogen production device in this embodiment includes a reactor with a reaction cover 8 and an insulating base 10, the electrodes of which are arranged on the insulating base 10 and connected to the high-voltage direct current power supply 5, and react There is a reactor outlet 15 on the cover 8; one end of the mixed gas pipeline is connected to the air inlet 3 on the outside of the insulating base, and the other end is connected to the air pump 6 and the methane gas source 1; the electrodes include conical inner electrodes 12 and a tubular outer electrode 13, wherein the inner electrode 12 is set at the center of the insulating base 10, and the outer electrode 13 is arranged around the inner electrode 12. The inner side of the outer electrode 13 has a wedge-shaped structure to assist t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com