Hydrotalcite loaded nickel catalyst as well as preparation method and application thereof

A catalyst and nickel-supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of catalyst stability and achieve good activity and stability, high specific surface area, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

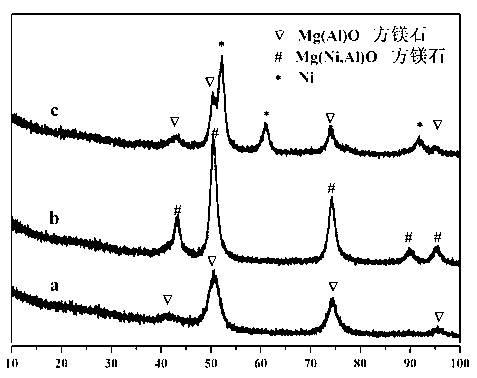

Embodiment 1

[0027] Example 1: The prepared MgAl-LDH was ground into powder and placed in a muffle furnace at 400°C for 4 h to obtain Mg(Al)O; 0.743 g Ni(NO 3 ) 2 6H 2 O was added to the Erlenmeyer flask to make a 25 mL solution, and then 0.85 g Mg(Al)O powder was added, then the temperature was controlled in a water bath at 80 °C, and magnetically stirred for 2 h. The resulting precipitate was filtered, dried at 110 °C for 12 h, and calcined at 800 °C for 4 h to obtain the catalyst.

Embodiment 2

[0028] Example 2: The preparation method is the same as in Example 1, except that the calcination temperature of MgAl-LDH is changed to 500°C.

Embodiment 3

[0029] Example 3: The preparation method is the same as in Example 1, except that the calcination temperature of MgAl-LDH is changed to 600°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com