Arsenic poisoning resistance and wide active temperature window integrated low-SO2-oxidation-ratio SCR (selective catalytic reduction) denitration catalyst and preparation method thereof

A technology of active temperature window and denitration catalyst, which is applied in the field of catalysts, can solve the problems of wide temperature window of catalysts and no consideration of anti-arsenic poisoning performance, adverse effects of catalyst activity, and no consideration of catalyst anti-arsenic poisoning ability, etc., to achieve anti-arsenic The effect of poisoning active temperature window, optimization of catalyst surface acidity, and reduction of SO2 oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

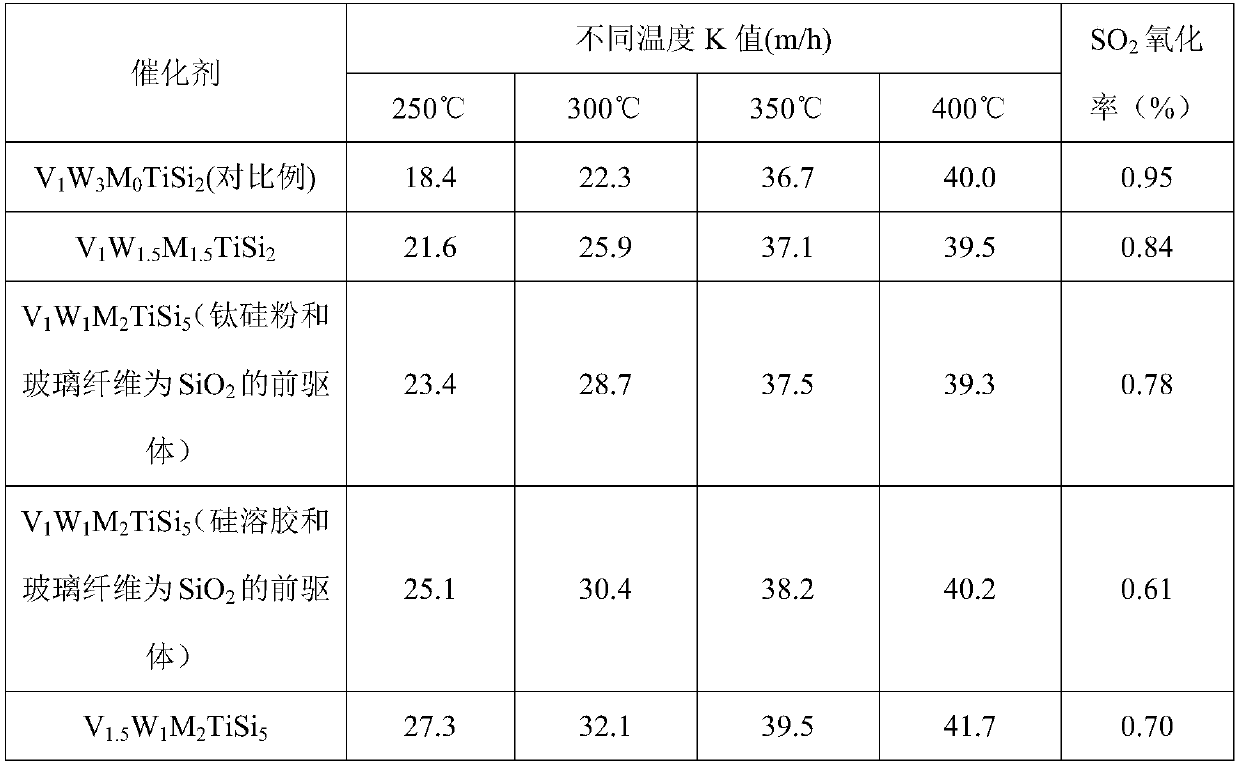

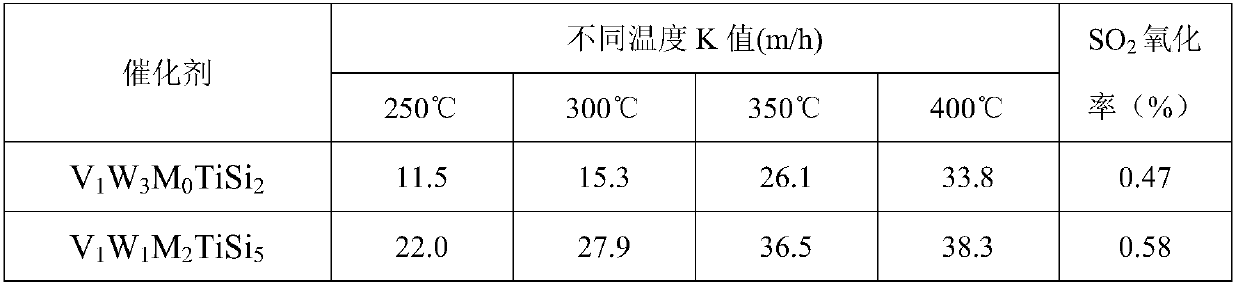

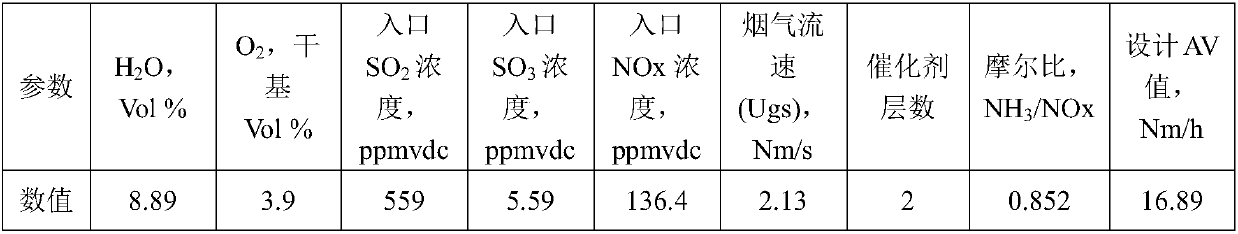

[0033] Table 1 Denitrification performance test data

[0034]

[0035] Note: SO 2 The oxidation rate is a test value at 400°C.

[0036] It can be seen from the above table 1 that the catalyst of the present invention has a wide window temperature range, between 250-400°C, and its catalytic performance is excellent, especially at 250-300°C, it can still maintain a higher catalytic performance than traditional catalysts ; and SO at 400°C 2 The oxidation rate is kept below 0.84%, which is lower than 0.95% of the comparison sample, and SO under the optimal catalyst formulation 2 The oxidation rate is only 0.61%, which meets the requirement of less than 0.75% in the "Guidelines for Best Available Techniques for Pollution Prevention and Control in Thermal Power Plants (Draft for Comment)". Illustrate that catalyst temperature window range of the present invention is wide, and lower SO 2 oxidation rate.

[0037] The content of each material in the specific embodiment refers t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com