Surface deposition honeycomb flue gas denitration catalyst and preparation method thereof

一种脱硝催化剂、表面沉积的技术,应用在催化剂活化/制备、化学仪器和方法、物理/化学过程催化剂等方向,能够解决价格昂贵、无法保证催化剂活性组分与活性载体结合、催化活性低等问题,达到利用率高、拓宽使用温度与应用范围、催化活性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

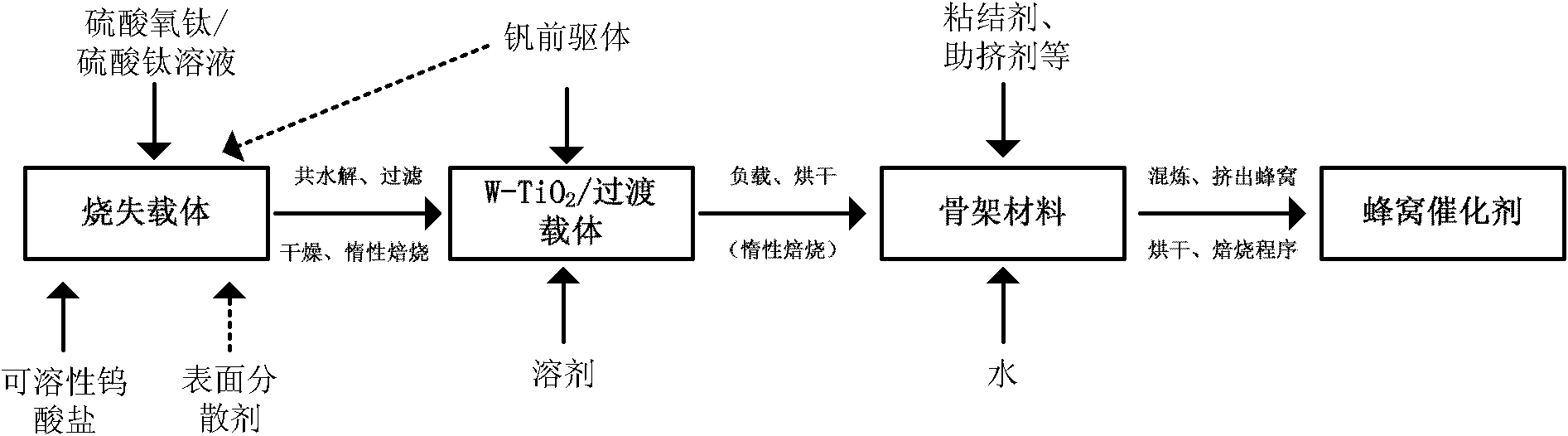

Method used

Image

Examples

Embodiment 1

[0058] 1. Preparation of composite carrier

[0059] 100g titanyl sulfate is dissolved in 150ml water, and its concentration is 4.1mol / L, adds Tween 20 surfactant 5g, and its mass concentration is 2%, urea 25g, adds 50g gac (surface area: 450m 2 / g, particle size 50-100μm), stir at 50°C for 2h, metatitanic acid nucleates once in the Martian carbon channels and surfaces, the mass ratio of titanium dioxide to the carrier obtained is 1:1, raise the temperature to 90°C, and continue stirring for 1h , gradually add an aqueous solution containing 7.5g of ammonium tungstate dropwise within 1 hour, filter and wash the reaction slurry to neutrality, dry at 100°C for 8 hours, and dry under N 2 In the atmosphere, the temperature was raised to 500° C. at a heating rate of 5° C. / min, and calcined for 5 hours to obtain 100 g of a composite carrier containing nano-titanium tungsten powder. XRD Characterization of TiO in Complex Support 2 It is anatase type, the diffraction peak intensity at...

Embodiment 2

[0065] 1. Preparation of composite carrier

[0066] 16g titanyl sulfate is dissolved in 1000ml water, and its concentration is 0.1mol / L, adds polyethylene glycol 2000 surfactant 10g, and its mass concentration is 1%, urea 50g, after stirring and dissolving at 50 ℃, add 80g gac to react 1h (nano Carbon black: 200m 2 / g, average particle size 2μm), metatitanic acid nucleates once in the pores and surface of activated carbon, the mass ratio of obtained titanium dioxide to carrier is 1:10, raise the temperature to 150°C and gradually add 1.5g sodium tungstate The aqueous solution continued to stir and react for 10h, and the treatment steps after slurry filtration were the same as those in step 1 of Example 1. XRD Characterization of TiO in Complex Support 2 It is anatase type, the diffraction peak intensity at the 26° position is 1600, TEM characterizes TiO 2 The particle size is 5-10nm. XRF Characterization of TiO in Composite Support 2 Content is 10wt%, carbon is 89wt%, WO ...

Embodiment 3

[0072] 1. Preparation of composite carrier

[0073] Dissolve 800g of titanyl sulfate in 1000ml of water, the concentration is 5mol / L, add 100g of span 80 surfactant, its mass concentration is 5%, 50g of urea, 50g of ammonium tungstate, 7.2g of vanadyl sulfate, stir and dissolve at 30°C Add 100g polystyrene microspheres (surface area: 200m 2 / g, particle size 2μm), reacted at 150°C for 10h (pressurized), and the treatment steps after slurry filtration were the same as those in step 1 of Example 1. V 2 o 5 The loading amount is TiO 2 1wt% of WO 3 The loading amount is TiO 2 10wt%, XRD characterization of TiO in the complex carrier 2 It is anatase type, the diffraction peak intensity at the 26° position is 1600, TEM characterizes TiO 2 The particle size is 5-10nm. XRF Characterization of TiO in Composite Support 2 Content is 80wt%, carbon is 11.2wt%, WO 3 8wt%, V 2 o 5 0.8wt.%.

[0074] 2. Preparation of honeycomb catalyst

[0075] 6.5kg of composite catalyst prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com