Monolithic SCR (Selective Catalytic Reduction) honeycomb catalyst for processing diesel exhaust and preparation method of catalyst

A honeycomb catalyst and exhaust gas treatment technology, applied in physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problems of poor low temperature and high temperature activity, simple components, easy deactivation, etc., and achieve high temperature stability. Good, simple preparation, wide active temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

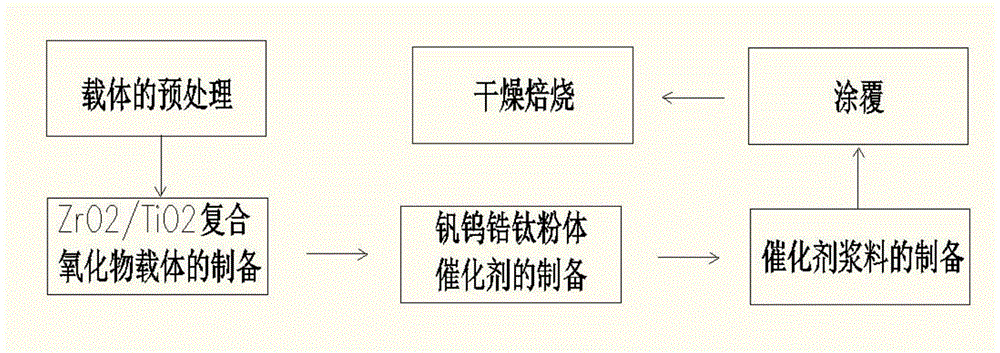

Method used

Image

Examples

Embodiment 1

[0027] a. Rinse a 350-mesh honeycomb ceramic carrier of 300mm*300mm*150mm with deionized water, and then dry it at 105°C for 5 hours for later use.

[0028] b. Weigh 2307g titanyl sulfate and dissolve it in water, stir continuously to dissolve it completely, and filter the solution to remove insoluble impurities therein, weigh 436g zirconium nitrate and dissolve it in water, mix titanyl sulfate solution and zirconium nitrate solution evenly The zirconium-titanium mixed solution was prepared, and the zirconium-titanium mixed solution and ammonia water were added into a reactor containing a small amount of water in parallel flow, and the pH value of the reaction solution was controlled to be 10 by adjusting the drip rate of ammonia water to obtain a white precipitate. The precipitate was suction-filtered, washed, detected with Ba(NO3)2, then dried at 105° C. for 12 hours, and calcined at 500° C. for 3 hours to obtain ZrO2 / TiO2 composite oxide carrier powder.

[0029] c. Weigh 50...

Embodiment 2

[0033] Embodiment 2: carry out according to the operating procedure of embodiment 1, adjust ferric nitrate to be 193.1g, cerium nitrate is 0g, lanthanum nitrate is 33.3g, binding agent is 71.6g, and glacial acetic acid is 50.1g, control catalyst slurry in step 4 The solid content of the material is 47.5%, the viscosity is 545Pa.S, and the pH value is 3.5. The dosage of other components, the preparation operation and the activity test method are the same as in Example 1. After testing, the NO conversion rate has reached more than 85%, and the highest is 100%. %.

Embodiment 3

[0034]Embodiment 3: Carry out according to the operation procedure of embodiment 1, adjust ammonium tungstate to be 117.9g, iron nitrate to be 193.1g, cerium nitrate to be 0g, praseodymium nitrate to be 33.1g, binding agent to be 35.8g, glacial acetic acid to be 50.1g , in step 4, the solid content of the catalyst slurry is controlled to be 50.5%, the viscosity is 415Pa.S, the pH value is 3.5, and the activity test reaction temperature is 180-530°C. The amount of other components, preparation operations and activity test methods are the same as those in Example 1 same. After testing, the conversion rate of NO has reached more than 90%, and the highest is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com