Composite smoke SCR (selective catalytic reduction) denitrification catalyst and preparation method thereof

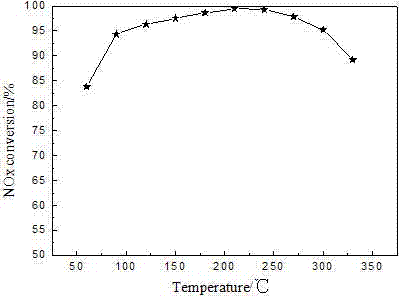

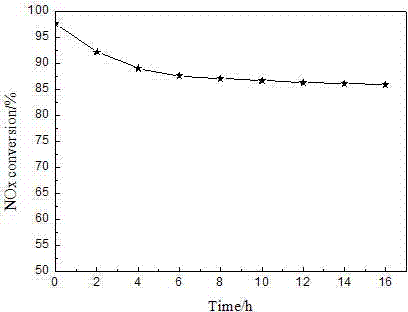

A composite catalyst and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult to achieve industrial production, difficult to deal with deactivated catalysts, and high catalyst preparation costs, and reach the active temperature. The effect of wide window, strong resistance to SO2 and H2O poisoning, and high SCR denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare flue gas SCR denitrification composite catalyst according to the method of the present invention, the preparation method is:

[0031] (1) Place the honeycomb ceramic carrier in an ultrasonic oscillator, pour in deionized water for ultrasonic cleaning, and then dry it. Continue to immerse the above dedusted carrier in 5% nitric acid solution and boil for 8 hours. After cooling, clean the surface layer of the carrier and the residual acid in the pores with deionized water, and then dry it for later use.

[0032] (2) Weigh the precursors of catalyst active components: manganese acetate, molybdenum nitrate and nickel nitrate according to the molar ratio of Mn / Mo / Ni 1:0.1:0.2, mix and dissolve them in 15ml of deionized water, and stir well A certain amount of co-catalyst precursor cerium nitrate is added to the solution to prepare a saturated solution, wherein the molar ratio of Mn element to co-catalyst precursor is 1:0.2.

Embodiment 2

[0049] Prepare flue gas SCR denitrification composite catalyst according to the method of the present invention, the preparation method is:

[0050] (1) Put the molecular sieve carrier into an ultrasonic oscillator, pour in deionized water for ultrasonic cleaning, and then dry it. Continue to immerse the above dedusted carrier in 14% citric acid solution and boil for 9 hours. After cooling, clean the surface layer of the carrier and the residual acid in the pores with deionized water, and then dry it for later use.

[0051] (2) Weigh the catalyst active component precursors: manganese chloride, molybdenum chloride and nickel nitrate according to the molar ratio of Mn / Mo / Ni element 1:0.3:0.1, mix and dissolve them in 20ml of deionized water, stir well After uniformity, add a certain amount of co-catalyst precursor copper nitrate and cerium acetate to the solution to obtain a saturated solution, wherein the molar ratio of Cu / Ce is 2:1, and the molar ratio of Mn element to co-cat...

Embodiment 3

[0057] Prepare flue gas SCR denitrification composite catalyst according to the method of the present invention, the preparation method is:

[0058] (1) Put the activated carbon carrier into an ultrasonic oscillator, pour in deionized water for ultrasonic cleaning, and then dry it. Continue to immerse the above dedusted carrier in 26% carbonic acid solution and boil for 10 hours. After cooling, clean the surface layer of the carrier and the residual acid in the pores with deionized water, and then dry it for later use.

[0059] (2) Weigh the precursors of catalyst active components: manganese nitrate, molybdenum chloride and nickel nitrate according to the molar ratio of Mn / Mo / Ni elements 1:0.4:0.9, mix and dissolve them in 17ml deionized water, and stir well Finally, add a certain amount of co-catalyst precursor chromium chloride and cerium chloride in the solution to obtain a saturated solution, wherein the element molar ratio of Cr / Ce is 1:1, and the molar ratio of Mn eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com