Titanium-based nano-composite metal oxide catalyst and preparation method thereof

A nano-composite and oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of narrow active temperature window, poor selectivity, low activity, etc. problem, to achieve the effect of fast combustion process, low cost and low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

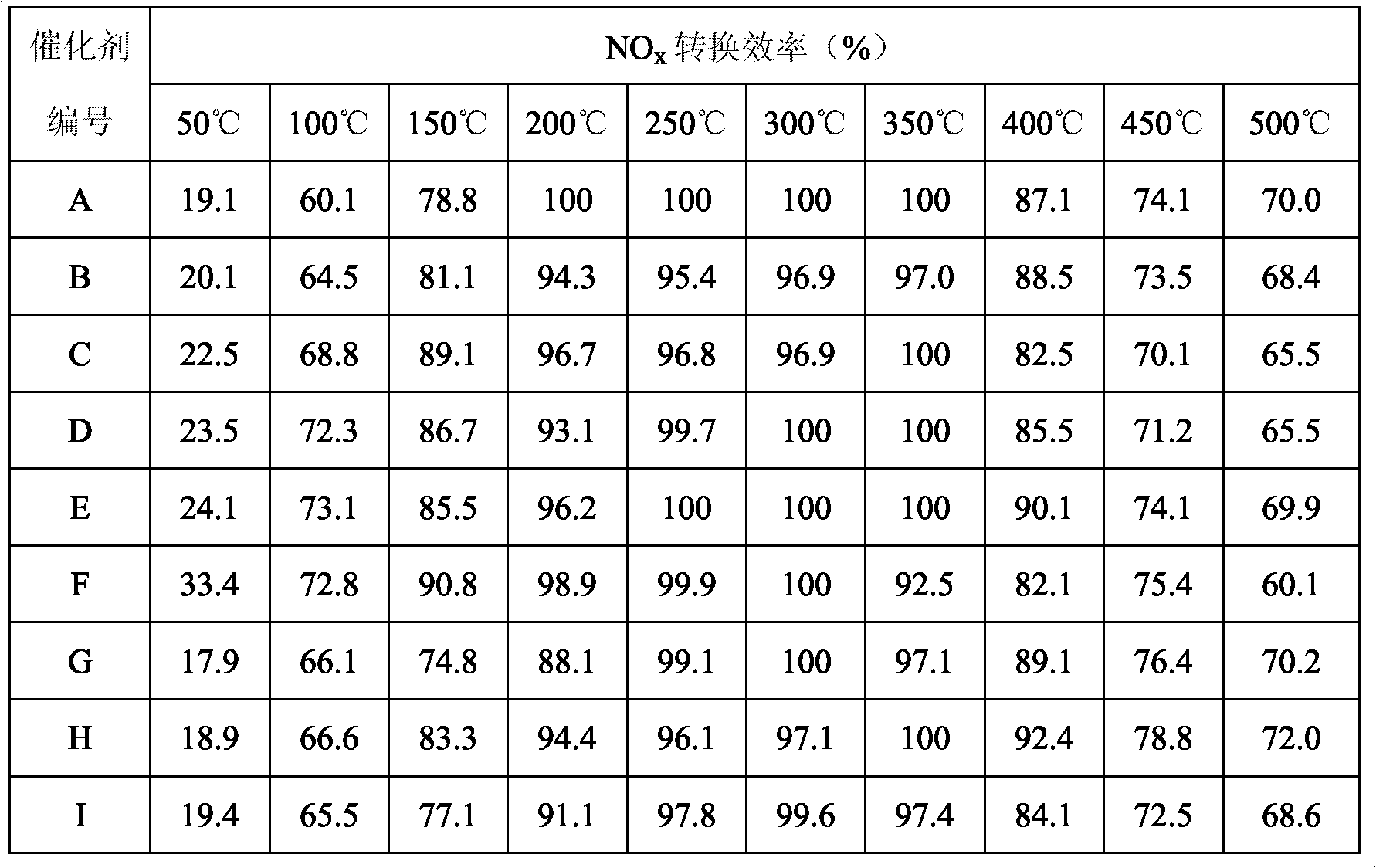

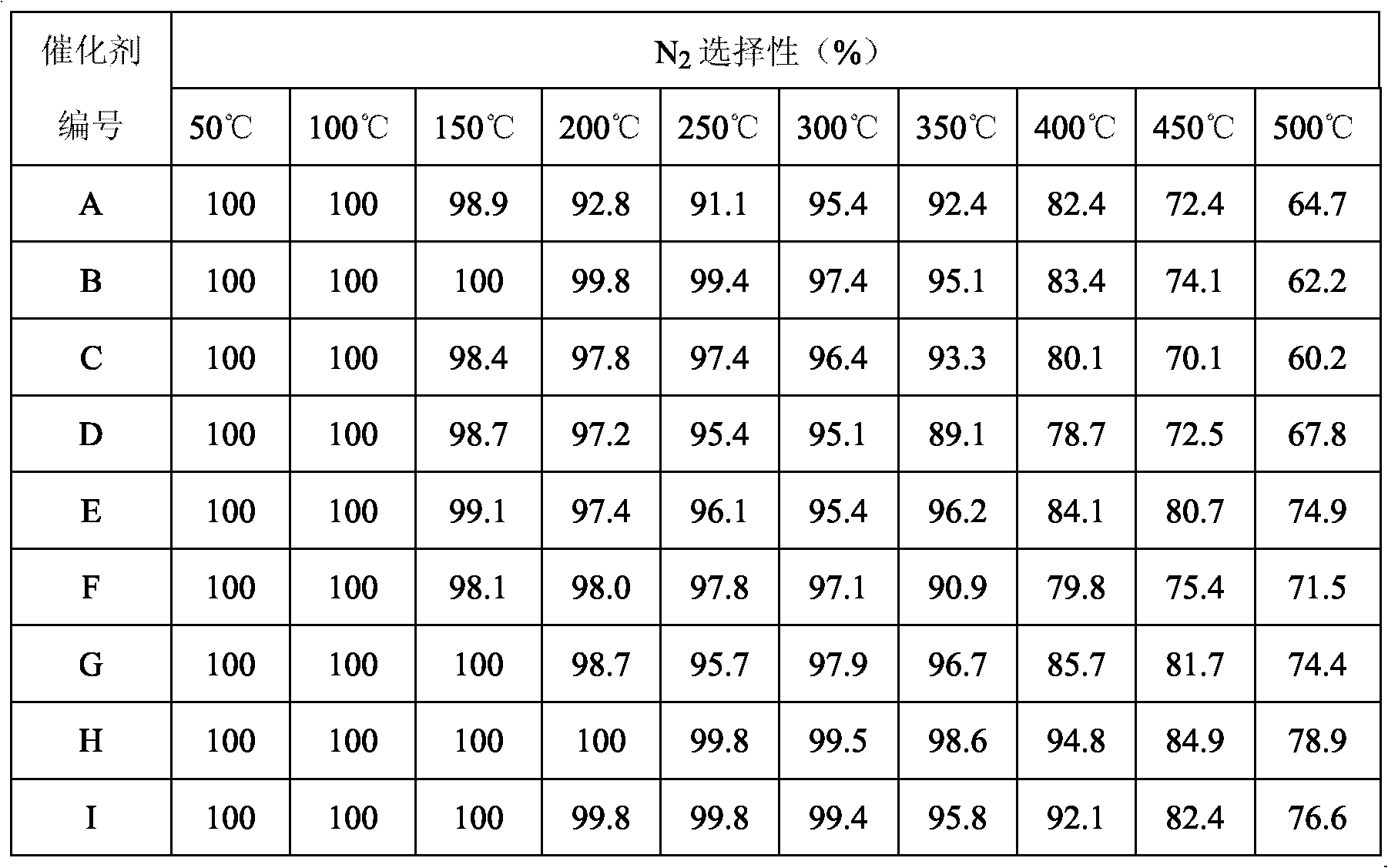

Examples

Embodiment 1

[0045] (1)TiO(NO 3 ) 2 Precursor preparation

[0046] According to the active ingredient VO x with carrier TiO 2 The molar ratio is 0.05:0.95, that is, the molecular formula of the synthesized catalyst is Ti 0.95 V 0.05 o 2-δ ,TiO 2 The loading capacity of the solution is 2g, and the calculated amount of tetra-n-butyl titanate is 8.526g. Weigh the corresponding mass of tetra-n-butyl titanate and stir continuously at room temperature. Under constant stirring, add 30ml of absolute ethanol gradually Add it dropwise to tetra-n-butyl titanate to carry out the alcoholysis of tetra-n-butyl titanate. After fully stirring, a light yellow solution is generated. After dripping the absolute ethanol, slowly add 40ml of deionized water for hydrolysis to obtain milky white TiO (OH) 2 solution, under constant stirring, drop into 27ml concentration again and be the nitric acid of 68% (volume ratio), continue to stir until mixed solution becomes transparent, clear solution after drippin...

Embodiment 2

[0055] (1)TiO(NO 3 ) 2 Precursor preparation

[0056] According to the active ingredient VO x with carrier TiO 2 The molar ratio is 0.1:0.9, that is, the synthesized catalyst molecular formula is Ti 0.9 V 0.1 o 2-δ ,TiO 2 The loading capacity of the solution is 2g, and the calculated amount of tetra-n-butyl titanate is 8.526g. Weigh the corresponding mass of tetra-n-butyl titanate and stir continuously at room temperature. Under constant stirring, add 30ml of absolute ethanol gradually Add it dropwise to tetra-n-butyl titanate to carry out the alcoholysis of tetra-n-butyl titanate. After fully stirring, a light yellow solution is generated. After dripping the absolute ethanol, slowly add 40ml of deionized water for hydrolysis to obtain milky white TiO (OH) 2 Solution, add 27ml concentration under constant stirring and be the nitric acid of 68% (volume ratio), continue to stir until mixed solution becomes transparent, clear solution after dripping, obtain TiO(NO 3 ) 2...

Embodiment 3

[0065] (1)TiO(NO 3 ) 2 Precursor preparation

[0066] According to the active ingredient VO x with carrier TiO 2 The molar ratio is 0.15:0.85, that is, the synthesized catalyst molecular formula is Ti 0.85 V 0.15 o 2-δ ,TiO 2The loading capacity of the solution is 2g, and the calculated amount of tetra-n-butyl titanate is 8.526g. Weigh the corresponding mass of tetra-n-butyl titanate and stir continuously at room temperature. Under constant stirring, add 30ml of absolute ethanol gradually Add it dropwise to tetra-n-butyl titanate to carry out the alcoholysis of tetra-n-butyl titanate. After fully stirring, a light yellow solution is generated. After dripping the absolute ethanol, slowly add 40ml of deionized water for hydrolysis to obtain milky white TiO (OH) 2 Solution, add 27ml concentration under constant stirring and be the nitric acid of 68% (volume ratio), continue to stir until mixed solution becomes transparent, clear solution after dripping, obtain TiO(NO 3 )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com