SCR catalyst for diesel exhaust purification and preparation method of SCR catalyst

An SCR catalyst and exhaust gas purification technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low temperature activity drop, activity drop, etc., and achieve high hydrothermal stability and wide active temperature window. , The effect of good resistance to hydrothermal aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Configure 1000mL neodymium nitrate solution, Nd in the solution 4+ The concentration is 0.2mol / L, heated to 70°C, 50g SAPO-34 molecular sieve powder is added while maintaining strong stirring, and ion exchange is carried out in a constant temperature reactor at 70°C, and the exchange time is 10h. The obtained slurry was filtered with filter cloth and washed with deionized water for three times. The obtained molecular sieve sludge was dried at a drying temperature of 105℃, air atmosphere, and the drying time was 24h. The dried molecular sieve sludge was twisted and finely passed through 100 mesh. screen. The powder obtained is recorded as Nd-SAPO-34.

[0048] Configure 500mL copper nitrate solution, Cu in the solution 2+ The concentration is 0.6mol / L, heated to 70°C, add 50g of Nd-SAPO-34 molecular sieve powder while maintaining vigorous stirring, and perform ion exchange in a constant temperature reactor at 70°C. The exchange time is 2h. The obtained slurry was filtered w...

Embodiment 2

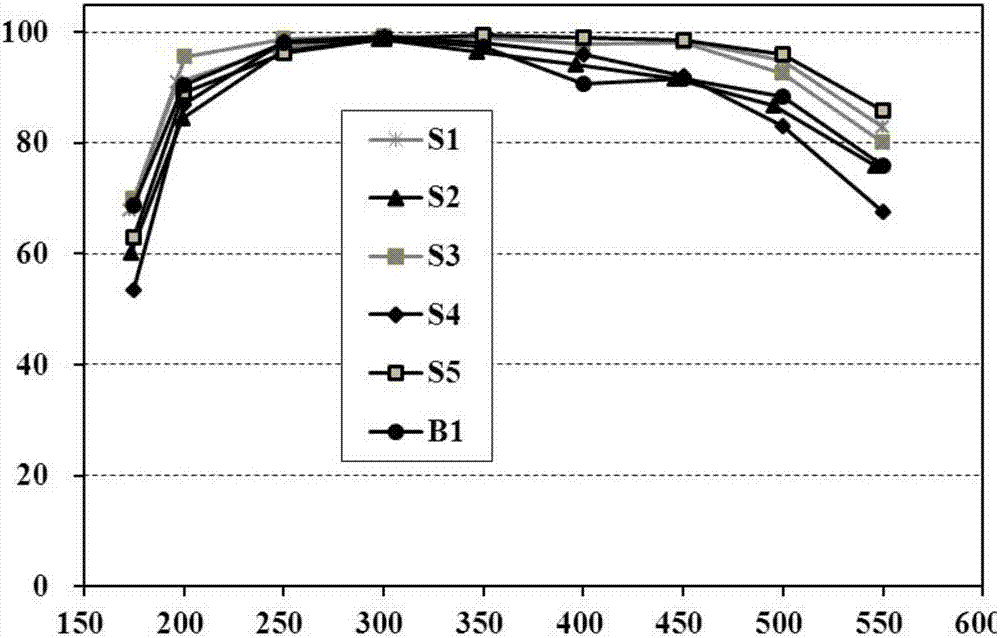

[0058] Prepare 1000mL of 0.1mol / L praseodymium nitrate solution, add 50g SAPO-34 molecular sieve powder and carry out ion exchange for 12h in a constant temperature reactor at 70°C. The obtained slurry is filtered, washed, and dried to obtain Pr-SAPO-34. Configure 500mL copper nitrate solution with a concentration of 0.6mol / L, add 50g Pr-SAPO-34 molecular sieve powder and carry out ion exchange for 3h in a constant temperature reactor at 70°C. The obtained slurry is filtered, washed, and dried. Repeat this ion exchange operation twice. The obtained molecular sieve powder is calcined in an air atmosphere. Other catalyst preparation processes and test conditions are the same as in Example 1. The resulting sample is referred to as S2.

Embodiment 3

[0060] Configure 1000mL of 0.2mol / L yttrium nitrate solution, add 50g SAPO-34 molecular sieve powder and carry out ion exchange in a constant temperature reactor at 70°C for 10h. The obtained slurry is filtered, washed, and dried to obtain Y-SAPO-34. Configure 500mL copper nitrate solution with a concentration of 0.2mol / L, add 50g Y-SAPO-34 molecular sieve powder and carry out ion exchange in a constant temperature reactor at 70°C for 3h. The obtained slurry is filtered, washed, and dried. Repeat this ion exchange operation four times. The obtained molecular sieve powder is calcined in an air atmosphere. Then the slurry is prepared, coated on the cordierite ceramic carrier, and then dried and calcined to obtain the monolithic SCR catalyst. The other operations are the same as in Example 1. The resulting sample is referred to as S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com