CO selective methanation catalyst and preparation method thereof

A methanation catalyst and selective technology, which is applied in the field of CO selective methanation catalyst and its preparation, can solve the problems that the reaction temperature is deeply affected by the gas space velocity, the catalyst reaction temperature is low, and the content of precious metals is high, so as to achieve catalyst utilization. High, catalytic activity and stability improvement, the effect of low amount of precious metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

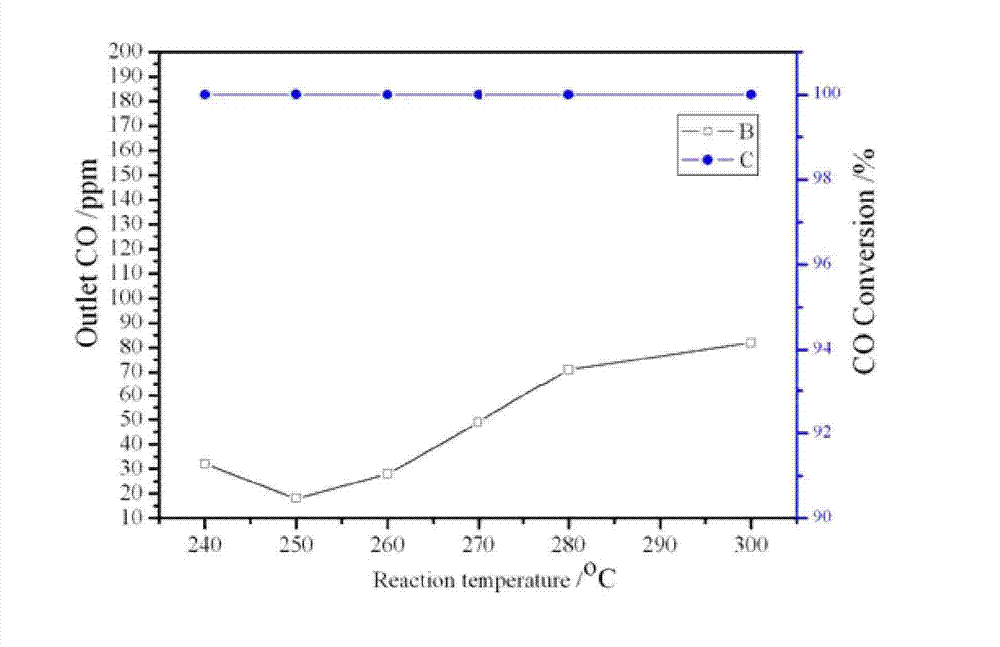

[0032] The catalyst evaluation method of Example 1 is as follows: the catalyst powder is pressed into tablets, then sieved, and catalyst particles of suitable size are selected and filled in a fixed-bed quartz reactor to evaluate the activity of the catalyst, wherein the reactor is a quartz tube reactor. , the inner diameter is φ16mm, the height is 700mm, and the percentage composition of dry gas in the reaction atmosphere is: H 2 75%, CO 2 18%, CO2%, air 5%, the water in the atmosphere is injected by the water pump, accounting for 10% of the total gas volume, the volume air velocity is 10000h -1 , which were evaluated under the simulated reformed gas atmosphere.

[0033]The catalyst evaluation method of Examples 2-6 is as follows: the catalyst is prepared into a monolithic catalyst and loaded into a fixed-bed quartz reactor to evaluate the activity of the catalyst, and the evaluation device and conditions are the same as above.

[0034] Example 1

[0035] A CO selective me...

Embodiment 2

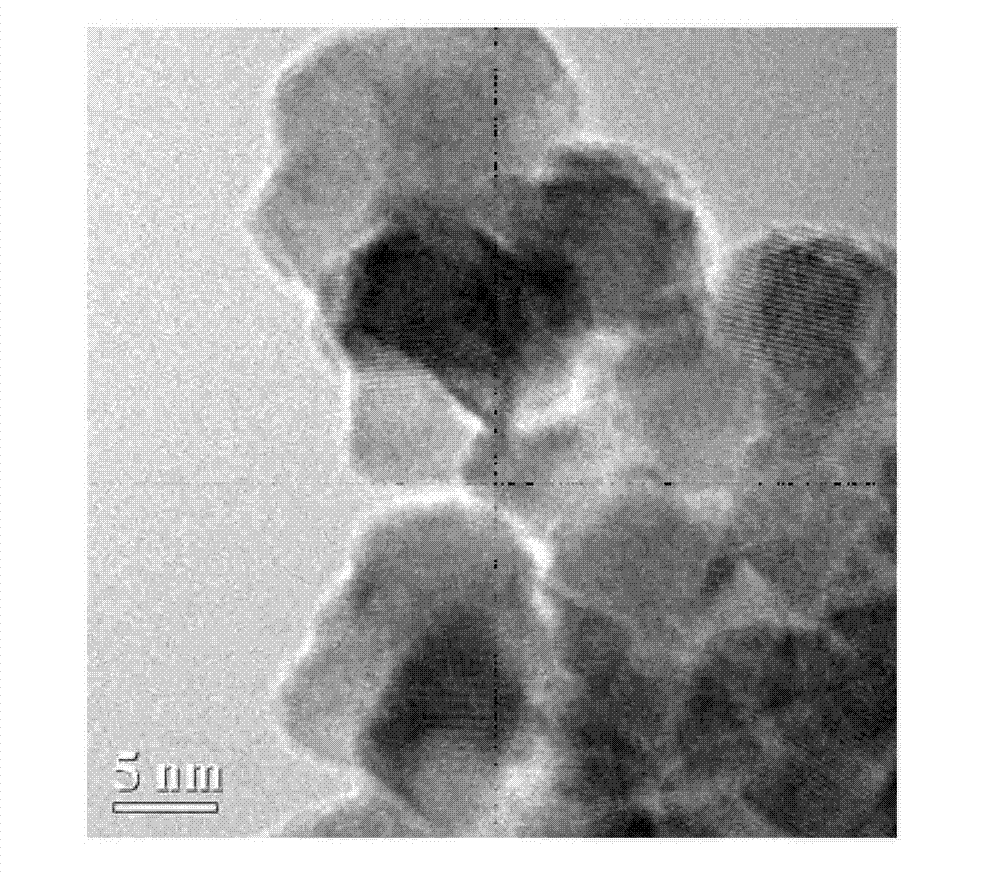

[0039] A CO selective methanation catalyst, comprising an active component Ru, and a nano-cerium-zirconium composite oxide carrier, wherein the molar ratio of Ce and Zr is 1:3; the content of Ru accounts for 0.2wt% of the catalyst; characterized by TEM ,like figure 1 As shown, the particle diameter of the nano-cerium zirconium composite oxide carrier is 5-20 nm, mostly 5-10 nm. The preparation method is as follows:

[0040] (1) Dissolve the nitrate of Ce:Zr with a molar ratio of 1:3 in deionized water, and configure it into a solution with a concentration of 0.2mol / L; dilute the industrial ammonia water with a concentration of 25% by 1.5 times as a precipitant, in continuous Under stirring, the above-mentioned salt solution was added dropwise to the above-mentioned precipitating agent at a rate of 5 ml / min, and the pH was controlled to 13. After the precipitation was complete, it was aged at room temperature for 6 h, washed with deionized water for 6 times, and replaced with ...

Embodiment 3

[0044] A CO selective methanation catalyst, comprising an active component Ru, and a nano-cerium-zirconium composite oxide carrier, wherein the molar ratio of Ce and Zr is 1:6; the content of Ru accounts for 2wt% of the catalyst; like figure 1 As shown, the particle diameter of the nano-cerium zirconium composite oxide carrier is 5-20 nm, mostly 5-10 nm. The preparation method is as follows:

[0045] (1) Dissolve the nitrate of Ce:Zr with a molar ratio of 1:6 in deionized water, and configure it into a solution with a concentration of 0.2mol / L; dilute the industrial ammonia water with a concentration of 25% by 1.5 times as a precipitating agent. Under stirring, the above-mentioned salt solution was added dropwise to the above-mentioned precipitating agent at a rate of 5 ml / min, and the pH was controlled to 11. After the precipitation was complete, it was aged at room temperature for 6 h, washed with deionized water for 6 times, and replaced with anhydrous ethanol to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com