Multifunctional environment catalytic material for tail gas purification and preparation method and application thereof

A technology for exhaust gas purification and catalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve strong application and promotion value, high mechanical strength, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

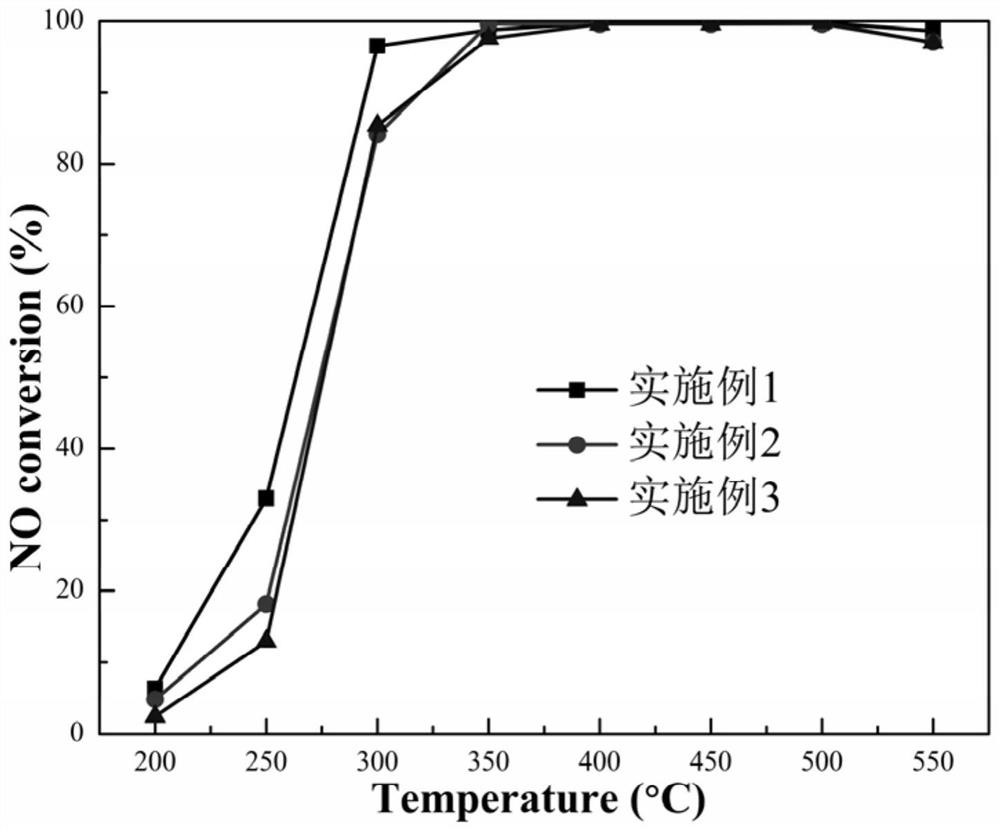

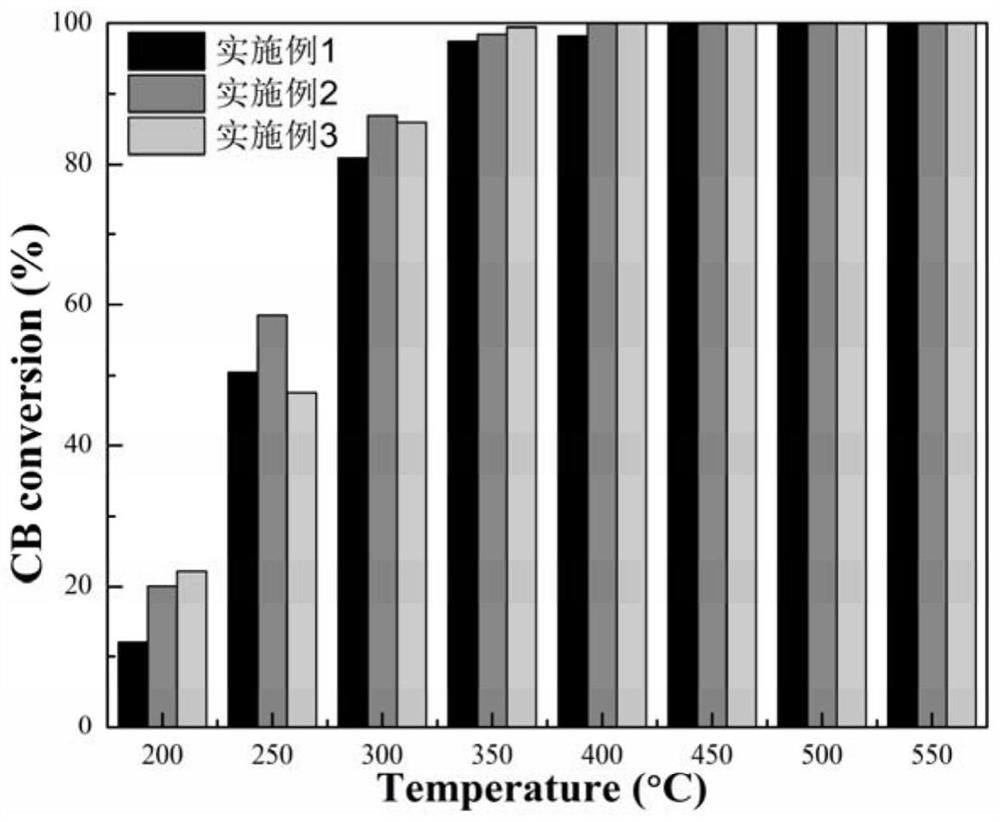

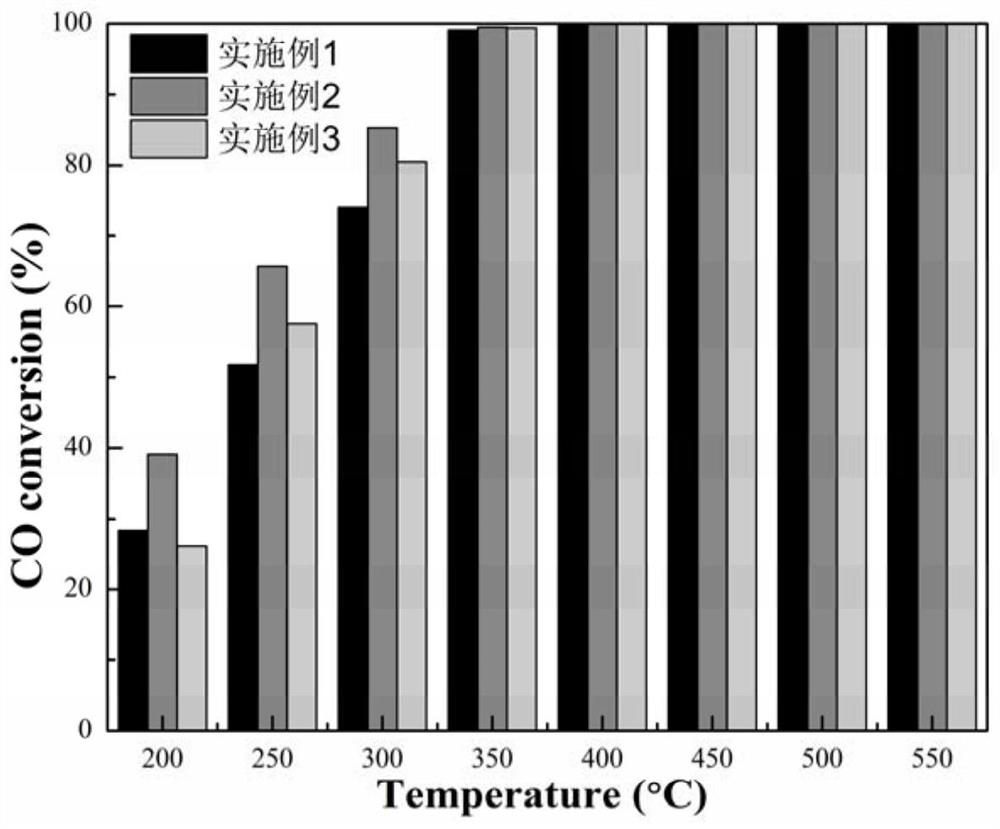

Embodiment 1

[0039] (1) carrier preparation

[0040] Weigh 100g of titanium dioxide and 10g of polyvinyl alcohol, add 500g of deionized water and stir evenly, stale for 12 hours, extrude into a strip-shaped carrier, dry in an oven at 80°C for 12h, and then roast in a muffle furnace at 500°C for 2h to obtain long strip carrier;

[0041] (2) Active component precursor solution preparation

[0042] Take by weighing 1.261g cerium nitrate hexahydrate, 2.058g manganese nitrate solution (50wt.%) and 1.519g copper nitrate trihydrate, add 48.380g deionized water and stir until the solution is clear and transparent, continue to add 9.676g glucose and at a temperature of Stirring and reacting at 80°C until the solution is clear and transparent and the viscosity reaches 2000-4000cP to prepare the active component precursor solution;

[0043] (3) Active component loading

[0044] Immerse the catalyst carrier prepared in step (1) in the cerium-manganese-copper composite oxide precursor solution prepa...

Embodiment 2

[0054] (1) carrier preparation

[0055] Weigh 100g of titanium dioxide and 10g of polyvinyl alcohol, add 500g of deionized water and stir evenly, stale for 12 hours, extrude into a strip-shaped carrier, dry in an oven at 80°C for 12h, and then bake in a muffle furnace at 700°C for 4h to obtain long strip carrier;

[0056] (2) Active component precursor solution preparation

[0057] Take by weighing 6.307g cerium nitrate hexahydrate, 6.175g manganese nitrate solution (50wt.%) and 3.037g copper nitrate trihydrate, add 155.190g deionized water and stir until the solution is clear and transparent, continue to add 31.038g glucose and at a temperature of Stirring and reacting at 80°C until the solution is clear and transparent and the viscosity reaches 2000-4000cP to prepare the active component precursor solution;

[0058] (3) Active component loading

[0059] Immerse the catalyst carrier prepared in step (1) in the cerium-manganese-copper composite oxide precursor solution prep...

Embodiment 3

[0069] (1) carrier preparation

[0070] Weigh 100g of titanium dioxide and 10g of polyvinyl alcohol, add 500g of deionized water and stir evenly, stale for 12 hours, extrude into a strip-shaped carrier, dry in an oven at 80°C for 12h, and then bake in a muffle furnace at 700°C for 2h to obtain long strip carrier;

[0071] (2) Active component precursor solution preparation

[0072] Take by weighing 6.307g cerium nitrate hexahydrate, 6.175g manganese nitrate solution (50wt.%) and 3.037g copper nitrate trihydrate, add 155.190g deionized water and stir until the solution is clear and transparent, continue to add 31.038g glucose and at a temperature of Stirring and reacting at 80°C until the solution is clear and transparent and the viscosity reaches 2000-4000cP to prepare the active component precursor solution;

[0073] (3) Active component loading

[0074] Immerse the catalyst carrier prepared in step (1) in the cerium-manganese-copper composite oxide precursor solution prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com