Wide-temperature vanadium-free denitration catalyst as well as preparation method and application thereof

A denitrification catalyst and reaction technology, applied in the field of flue gas purification, can solve the problems of harmful products, narrow active temperature range, unstable denitrification efficiency, etc., achieve strong water and sulfur resistance, wide active temperature range, and benefit The effect of recycling and regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the present invention uses metal precursors and HY molecular sieve as the main active component as raw materials, and adopts the ultrasonic ion exchange method to form a wide temperature vanadium-free denitration catalyst on the surface of the HY molecular sieve substrate. In this application, the following steps are included:

[0035] A method for preparing a wide-temperature vanadium-free denitration catalyst, characterized in that the method comprises the following steps:

[0036] Step 1. Dissolving the chromium-containing precursor, the iron-containing precursor and the copper-containing precursor in deionized water, and stirring in a water bath at 20-30°C for 30-60 minutes to obtain a mixed solution;

[0037] Step 2. Add the pretreated HY molecular sieve to the mixed solution obtained in step 1, and heat it in a water bath to 70-80°C under stirring conditions to obtain a viscous mixture;

[0038] Among them, the pretreated HY molecular sie...

Embodiment 1

[0044] Take 1.5gCr(NO 3 ) 2 9H 2 O, 7.5g FeSO 4 ·7H 2 Pour O into a 100ml beaker, add 40ml deionized water to dissolve; then weigh 0.75g Cu(NO 3 ) 2 ·3H 2 O was added to a beaker and stirred in a water bath at 20°C for 30 minutes; then 15 g of pretreated HY molecular sieves were added to the beaker and stirred for 60 minutes; heated in a water bath at 80°C while stirring and evaporating until a viscous mixture was obtained; 24h; then drying at 190°C for 12h; calcining at 450°C for 5h (the heating rate is controlled at 5-8°C / h), and natural cooling to obtain the finished catalyst.

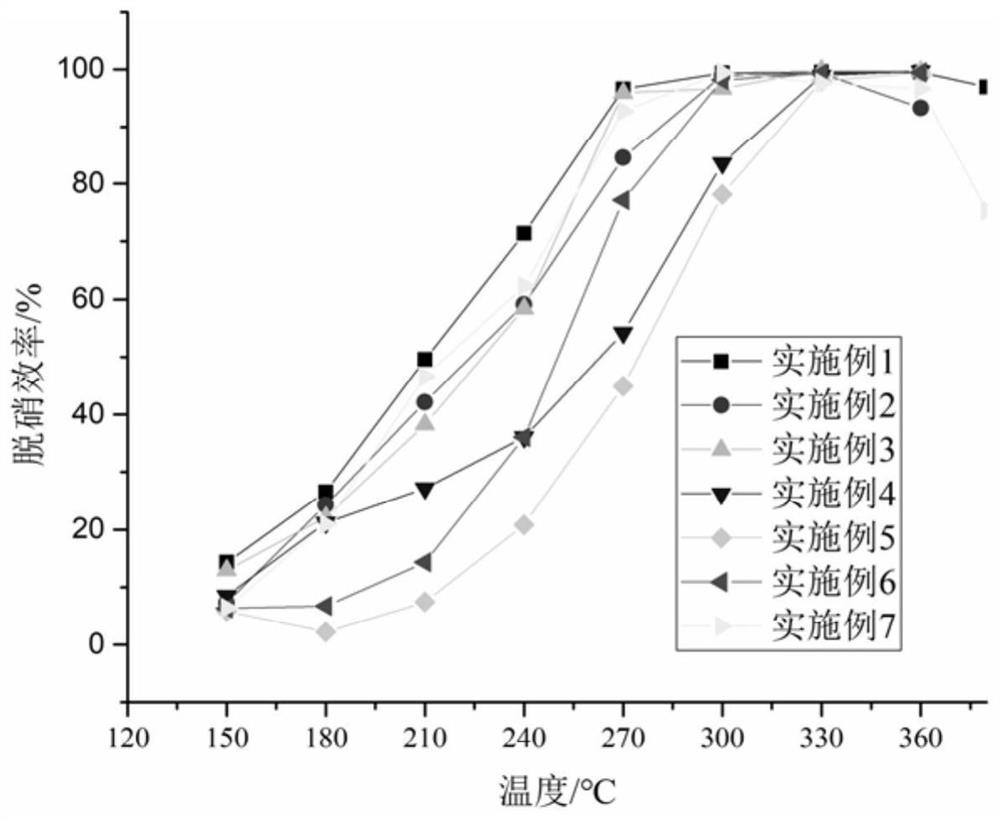

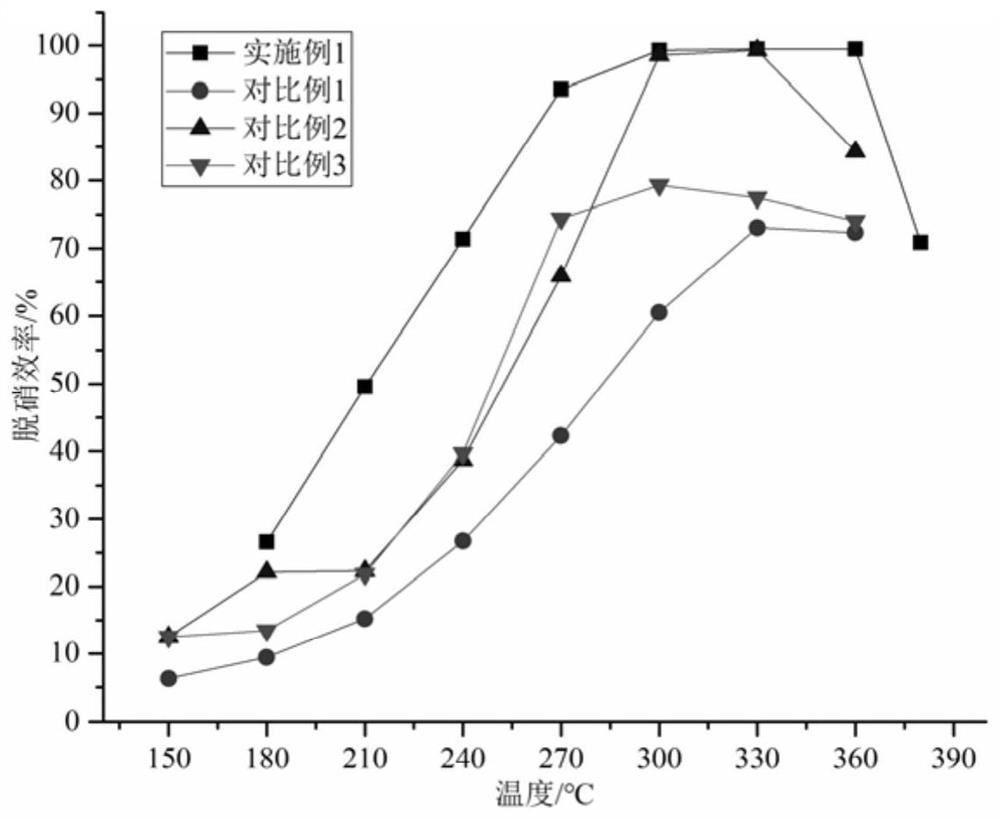

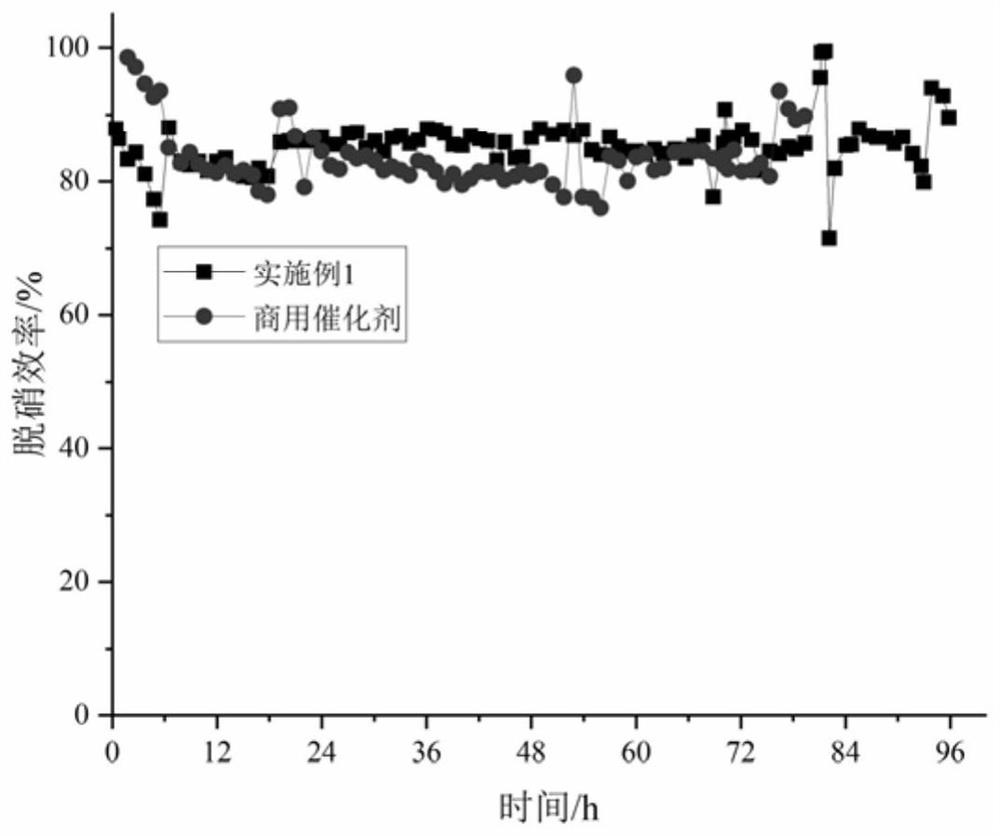

[0045] Using the wide temperature vanadium-free denitration catalyst prepared in Example 1, carry out NH 3 -SCR denitrification reaction experiment to test the influence of reaction temperature changes on denitrification efficiency.

[0046]The specific reaction conditions of the denitration reaction experiment are: the volume concentration of oxygen is 40000ppm, the volume concentration of ...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is: the added Cr(NO 3 ) 2 9H 2 The quality of O is 1.0g, and other preparation steps and preparation conditions are the same as in Example 1.

[0053] Then NH was carried out with the prepared catalyst 3 - SCR denitrification reaction experiment, checking the influence of reaction temperature change on the denitrification efficiency, the specific reaction conditions of the denitrification reaction experiment are the same as in Example 1.

[0054] like figure 1 As shown, the catalyst prepared in this example has a higher denitrification efficiency in the range of 250-360°C, and the denitrification efficiency of the catalyst can reach more than 80% at 270°C-360°C. It shows that the activity range of the catalyst prepared in this example is relatively wide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com