Method for preparing hexamethylenediamine

A preparation process, the technology of hexamethylenediamine, applied in the direction of reductive alkylation preparation, metal/metal oxide/metal hydroxide catalyst, organic chemistry, etc., can solve the problem of high toxicity of adiponitrile, dependence on imports, high price, etc. problems, achieve the effects of reducing the occurrence of side reactions, low cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

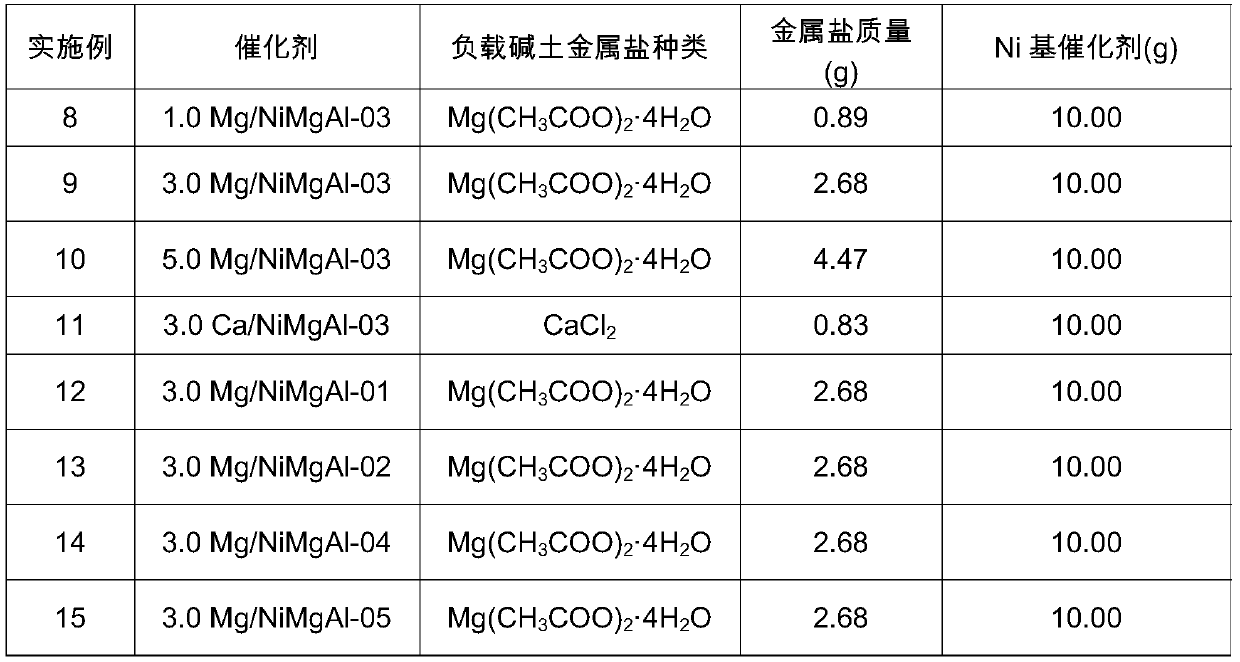

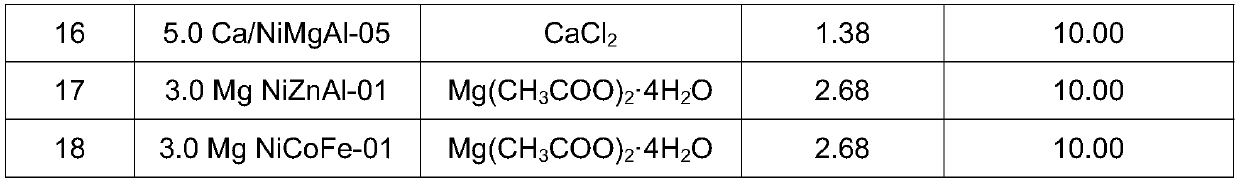

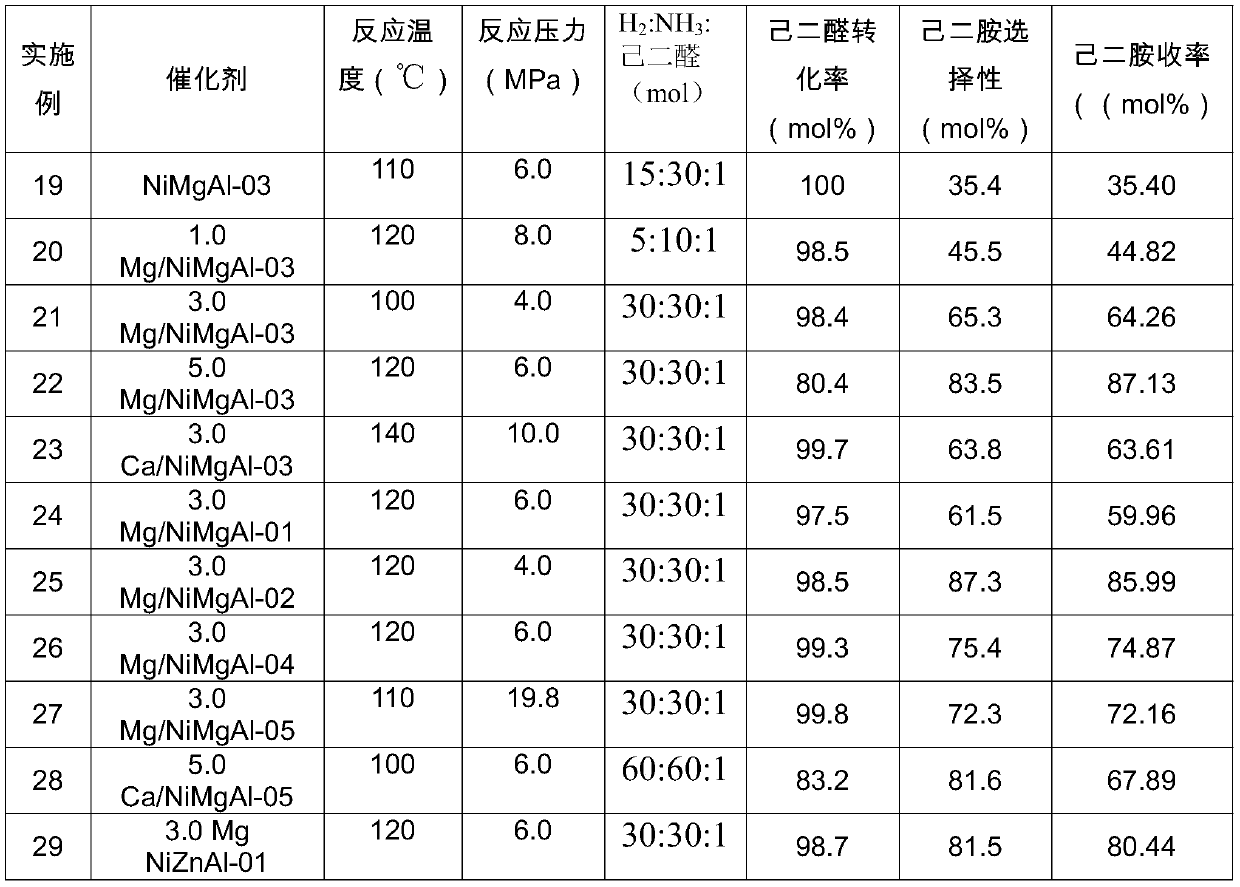

Examples

Embodiment 1

[0049] Embodiment 1 prepares NiMgAl-01 catalyst with hydrotalcite as precursor, (Ni 2+ +Mg 2+ ):Al 3+ The ratio is 3:1, Ni 2+ : Mg 2+ The ratio is 0.1.

[0050] 9.52gNi(NO 3 ) 2 ·6H 2 O, 46.89gAl(NO 3 ) 3 9H 2 O and 83.92gMg(NO 3 ) 2 ·6H 2 O is completely dissolved in 500ml of water to obtain mixed solution I; weigh 26.5gNa 2 CO 3 and 70g of NaOH were completely dissolved in 1L of water to obtain the mixed solution II; the two mixed solutions were slowly added dropwise to 200mL of water at the same time, vigorously stirred at a speed of 600r / min, and the pH was maintained at 10. After the addition was completed, the obtained colloidal suspension Transfer to an oven, age at 65°C for 72h, wash with distilled water until neutral, and dry to obtain Ni-based hydrotalcite, and further roast the obtained Ni-based hydrotalcite precursor at 500°C for 4h to obtain highly dispersed Ni base catalyst.

Embodiment 2

[0051] Embodiment 2 prepares NiMgAl-02 catalyst with hydrotalcite as precursor, (Ni 2+ +Mg 2+ ):Al 3+ The ratio is 3:1, Ni 2+ : Mg 2+ The ratio is 1.0.

[0052] 52.34gNi(NO 3 ) 2 ·6H 2 O, 46.89gAl(NO 3 ) 3 9H 2 O and 46.15gMg(NO 3 ) 2 ·6H 2 O is completely dissolved in 500ml of water to obtain mixed solution I; weigh 26.5gNa 2 CO 3 and 70g of NaOH were completely dissolved in 1L of water to obtain the mixed solution II; the two mixed solutions were slowly added dropwise to 200mL of water at the same time, vigorously stirred at a speed of 600r / min, and the pH was maintained at 10. After the addition was completed, the obtained colloidal suspension Transfer to an oven, age at 65°C for 72h, wash with distilled water until neutral, and dry to obtain Ni-based hydrotalcite, and further roast the obtained Ni-based hydrotalcite precursor at 500°C for 4h to obtain highly dispersed Ni base catalyst.

Embodiment 3

[0053] Embodiment 3 prepares NiMgAl-03 catalyst with hydrotalcite as precursor, (Ni 2+ +Mg 2+ ):Al 3+ The ratio is 3:1, Ni 2+ : Mg 2+ The ratio is 3.0

[0054] 78.52gNi(NO 3 ) 2 ·6H 2 O, 46.89gAl(NO 3 ) 3 9H 2 O and 23.07gMg(NO 3 ) 2 ·6H 2 O is completely dissolved in 500ml of water to obtain mixed solution I; weigh 26.5gNa 2 CO 3 and 70g of NaOH were completely dissolved in 1L of water to obtain the mixed solution II; the two mixed solutions were slowly added dropwise to 200mL of water at the same time, vigorously stirred at a speed of 600r / min, and the pH was maintained at 10. After the addition was completed, the obtained colloidal suspension Transfer to an oven, age at 65°C for 72h, wash with distilled water until neutral, and dry to obtain Ni-based hydrotalcite, and further roast the obtained Ni-based hydrotalcite precursor at 500°C for 4h to obtain highly dispersed Ni base catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com