Denitrifying honeycomb heat accumulator and preparation method thereof

A regenerator and honeycomb technology, which is applied in the field of denitrification honeycomb regenerators, can solve the problems that other methods are in the experimental research stage or pilot test stage, etc., and achieves significant emission reduction effect, improved wear resistance and corrosion resistance, and saves energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

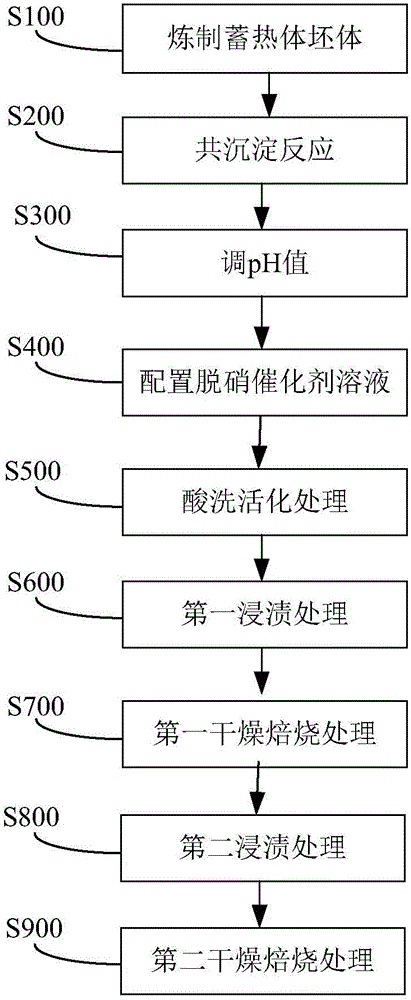

Method used

Image

Examples

Embodiment 1

[0090] Utilize the method for the embodiment of the present invention to prepare the nitric acid honeycomb heat accumulator, specifically as follows:

[0091] (1) Refining of heat storage body body

[0092] Mix 28g of burnt gemstone, 30.4g of cordierite, 7.2g of kaolin, 14.4g of quartz, 2.59g of carbide slag powder, 0.5g of methylcellulose and 0.91g of glycerin, and add an appropriate amount of deionized water for kneading and refining to obtain mud Material spare.

[0093] The mud block is aged, the temperature of the aging environment is 30°C, and the aging time is 48 hours. After vacuum refining and vacuum extrusion, it is made into a honeycomb body blank of the required specification.

[0094] Then, the honeycomb body blank is sent to a dryer for shaping and drying, and fired at 1200°C to obtain a heat storage body blank.

[0095] (2)TiO 2 -Al 2 o 3 Preparation of composite oxides

[0096] Take 12.13g of titanyl sulfate and 5.06g of aluminum chloride, dissolve them i...

Embodiment 2

[0110] (1) Refining of heat storage body body

[0111] Mix 21g of burnt gemstone, 28g of cordierite, 7.7g of kaolin, 13.3g of quartz, 5g of carbide slag powder, 1g of methyl cellulose and 2g of glycerin, and add an appropriate amount of deionized water for kneading and refining to obtain mud for later use.

[0112] The mud block is aged, the temperature of the aging environment is 25°C, and the aging time is 48 hours. After vacuum refining and vacuum extrusion, it is made into a honeycomb body blank of the required specification.

[0113] Then, the honeycomb body blank is sent to a dryer for shaping and drying, and fired at 1200°C to obtain a heat storage body blank.

[0114] (2)TiO 2 -Al 2 o 3 Preparation of composite oxides

[0115] Take 10.74g of titanyl sulfate and 8.96g of aluminum chloride, dissolve them in an appropriate amount of deionized water, and stir them evenly to prepare titanium source and aluminum source solutions respectively, and the concentration ratio ...

Embodiment 3

[0129] (1) Refining of heat storage body body

[0130] Mix 17.4g of burnt gemstone, 30g of cordierite, 4.2g of kaolin, 8.4g of quartz, 8.16g of calcium carbide slag powder, 3.79g of methylcellulose and 3.05g of glycerin, and add an appropriate amount of deionized water for kneading and refining to obtain mud Material spare.

[0131] The mud block is aged, the temperature of the aging environment is 30°C, and the aging time is 48 hours. After vacuum refining and vacuum extrusion, it is made into a honeycomb body blank of the required specification.

[0132] Then, the honeycomb body blank is sent to a dryer for shaping, drying, and firing at 1200°C to obtain a finished product.

[0133] (2)TiO 2 -Al 2 o 3 Preparation of composite oxides

[0134] Take 10.99g of titanyl sulfate and 18.32g of aluminum chloride, dissolve them in an appropriate amount of deionized water, and stir them evenly to prepare titanium source and aluminum source solutions respectively, and the concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com