Rarefied-burning automobile exhaust gas catalyzing and purifying method and apparatus

A technology for automobile exhaust and catalytic purification, which is applied in the direction of exhaust devices, chemical instruments and methods, and mufflers, etc. It can solve the problems of excessive hydrocarbon concentration in exhaust gas, insufficient reduction efficiency of nitrogen oxides, and narrow active temperature range. , to achieve the effect of broadening the reduction activity temperature range, broadening the activity temperature range, and improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

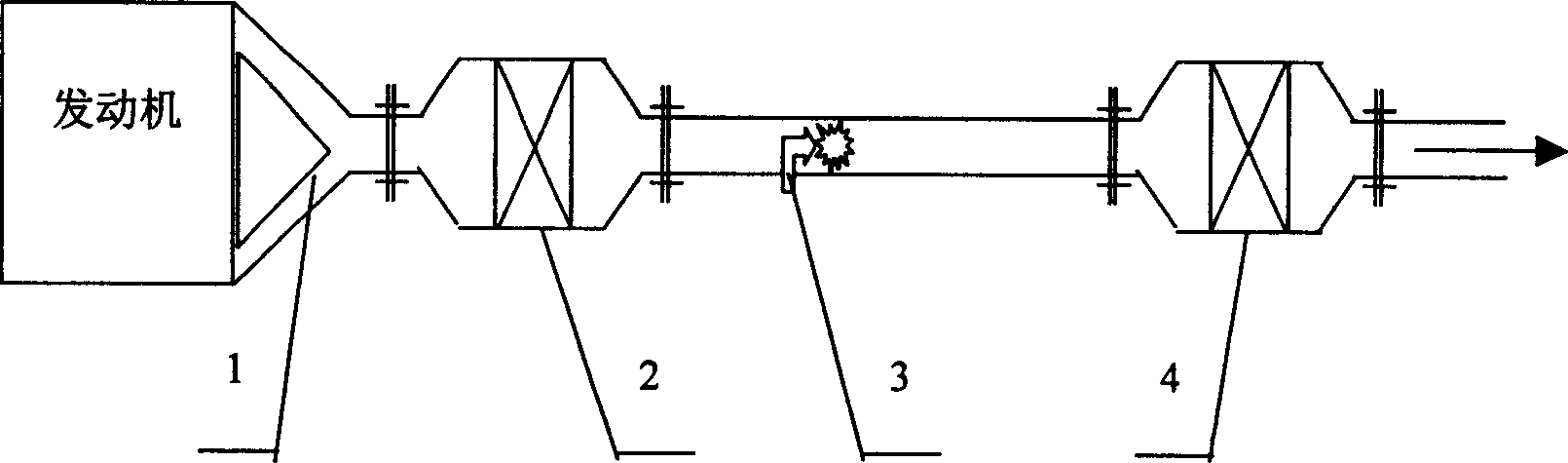

Image

Examples

Embodiment 1

[0020] Simulate lean-burn vehicle exhaust by 1100ppmNO, 600ppmC 3 h 6 , 3000ppmCO, 5%O 2 , 10%H 2 O and 80ppmSO 2 , and the rest are N 2 composition. Ag / Al prepared by sol-gel method in both catalytic reaction beds 2 o 3 (Ag content of 5%) as a catalyst. Methanol (CH 3 OH), after mixing with the outlet gas of the first reaction bed, the concentration of methanol is 2500ppm. When the airspeed is 42,000h -1 , when the temperature of the first catalytic reaction bed is 450-550°C, and the temperature of the second catalytic reaction bed is 300-400°C. The NOx purification efficiency is 75%-85%, the hydrocarbon purification efficiency is 89%-98%, and the carbon monoxide purification efficiency is 88%-99%.

Embodiment 2

[0022] Simulate lean-burn vehicle exhaust by 1100ppmNO, 1100ppmC 3 h 6 , 3000ppmCO, 5%O 2 , 10%H2 O and 80ppmSO 2 , and the rest are N 2 composition. Ga 2 o 3 / Al 2 o 3 as a catalyst (Ga 2 o 3 The content is 27%), the Co / Al prepared by the impregnation method in the second catalytic reaction bed 2 o 3 (Co content is 2%) as a catalyst. Methanol (CH 3 OH), after mixing with the outlet gas of the first reaction bed, the concentration of methanol is 2500ppm. When the airspeed is 100,000h -1 , when the temperature of the first catalytic reaction bed is 470-570°C, and the temperature of the second catalytic reaction bed is 320-420°C. The NOx purification efficiency is 60%-69%, the hydrocarbon purification efficiency is 80%-89%, and the carbon monoxide purification efficiency is 83%-94%.

Embodiment 3

[0024] Simulate lean-burn vehicle exhaust by 1000ppmNO, 1000ppmC 3 h 6 , 3000ppmCO, 8%O 2 , 10%H 2 O and 80ppmSO 2 , and the rest are N 2 Composition, Ga 2 o 3 / Al 2 o 3 (Ga 2 o 3 The content is 27%) as catalyst, the Ag / Al prepared by sol-gel method in the second catalytic reaction bed 2 o 3 (Ag content of 5%) as a catalyst. Between the first and the second catalytic reaction bed, inject ethanol (C 2 h 5 OH), after mixing with the first reaction bed outlet gas, the ethanol concentration is 2000ppm. When the airspeed is 60,000h -1 , when the reaction temperature of the first catalytic reaction bed is 470-570°C, and the reaction temperature of the second catalytic reaction bed is 350-450°C. The NOx purification efficiency is 74%-87%, the hydrocarbon purification efficiency is 83%-95%, and the carbon monoxide purification efficiency is 87%-96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com