Kelp-shaped Mn-Fe double-metal oxide loaded CeO2 catalyst, preparation method thereof and application of catalyst

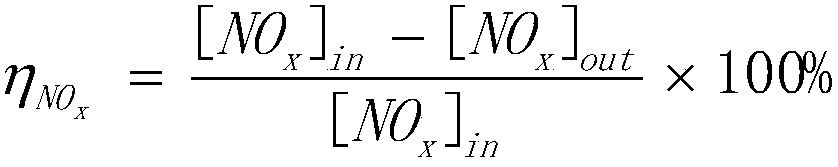

A bimetallic oxide and catalyst technology, applied in the field of flue gas denitration, can solve the problems of low selectivity of supported denitration catalysts, difficult fixing of active components, narrow catalyst activity window, etc., and achieves excellent anti-SO2 performance, strong bonding, The effect of wide active temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

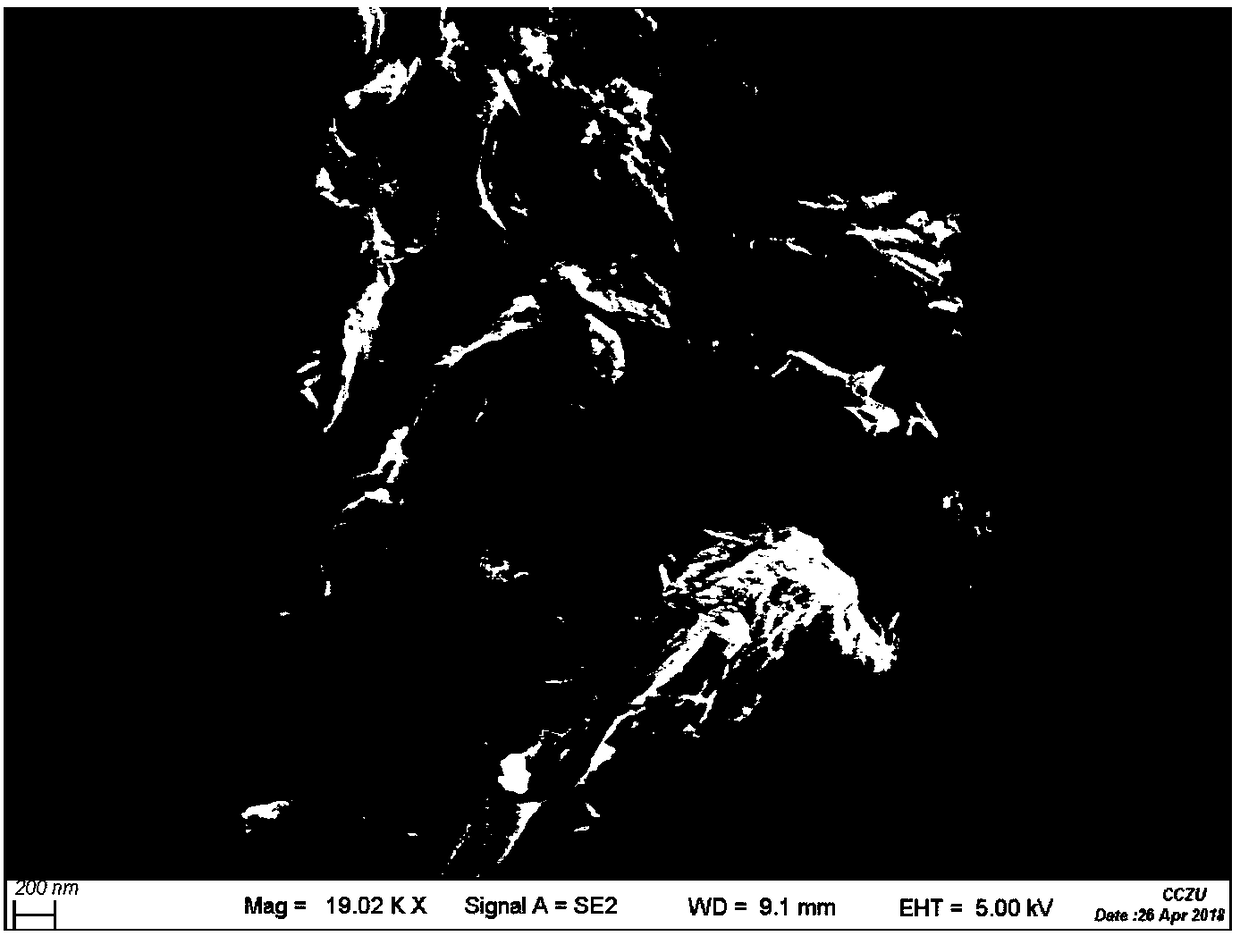

Image

Examples

Embodiment 1

[0029] (1) 1.5g manganese acetate and 2.5g ferric sulfate were dissolved in deionized water respectively, and ultrasonically dispersed to obtain manganese acetate solution and ferric sulfate solution;

[0030] (2) Mix the manganese acetate solution obtained in step (1) with the ferric sulfate solution, and add 1.6 g of urea to magnetically stir for 0.5 h at room temperature to obtain a mixed solution;

[0031] (3) Add ammonia solution dropwise to the mixed solution prepared in step (2) while stirring, adjust to pH=10, and continue stirring for 3 h.

[0032] (4) The mixed solution obtained in step (3) was transferred to a polytetrafluoroethylene hydrothermal kettle with a volume capacity of 100 ml and reacted at 90° C. for 6 h. suction filtration, washing and drying to obtain the pleated kelp-shaped Mn-Fe composite oxide catalyst precursor.

[0033] (5) Get the catalyst in step (4), dissolve it in 200ml deionized water, add 1.9g of Ce(NO 3 ) 3 ·6H 2 O, also adjust the pH to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com