Rare-earth heteropolyacid salt-doped iron-based catalyst and application of catalyst in flue gas denitration

A technology of iron-based catalysts and heteropoly acid salts, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high cost and operating temperature, environmental and human toxicity, active component vanadium Toxic and other problems, to achieve the effect of strong anti-sulfur poisoning ability, low investment and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of Rare Earth Heteropolyacid Salt Doped Iron-Based Catalyst

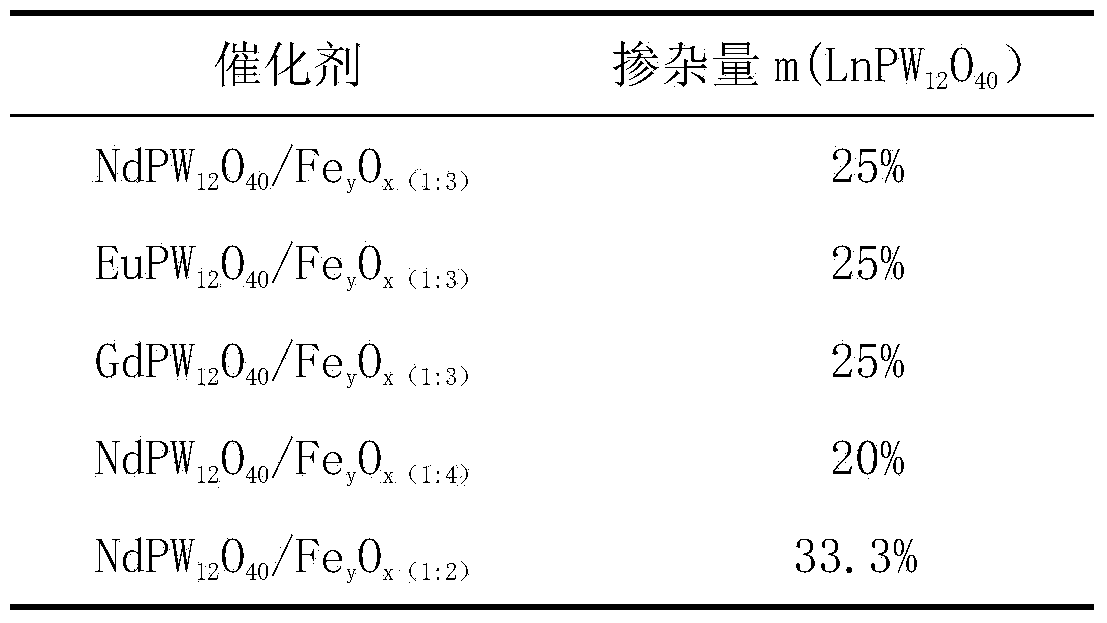

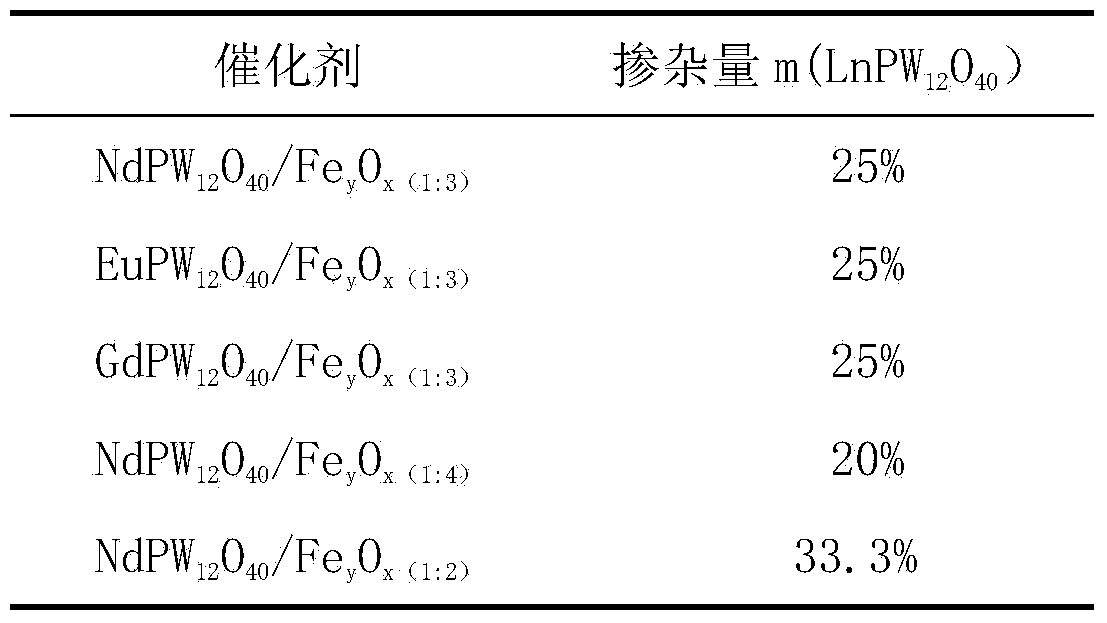

[0023] Rare earth heteropolyacid salt-doped iron-based catalyst, composed of rare earth heteropolyacid salt and iron oxide mechanically mixed, the mass ratio of rare earth heteropolyacid salt to iron oxide is 1:2, 1:3 or 1:4, including 5 kinds described in table 1. Its preparation method is as follows:

[0024] (1) Keggin structure rare earth phosphotungstate (LnPW 12 o 40 , Ln=Nd, Nd, Eu):

[0025] (1) Accurately weigh 8.964g (3.0mmol) of phosphotungstic acid, add 30ml 1+1 ethanol to dissolve it;

[0026] (2) Add excessive 10% rare earth nitrates under vigorous stirring at 75° C., and continue to react for 45 minutes; Salt);

[0027] (3) After the above reaction is completed, distill at normal pressure (remove ethanol and water, distill to 1 / 4 of the original volume), cool and crystallize naturally, filter, dry the filter cake at 120°C for 2h, and then roast at 300°C for 3h, namely...

Embodiment 2

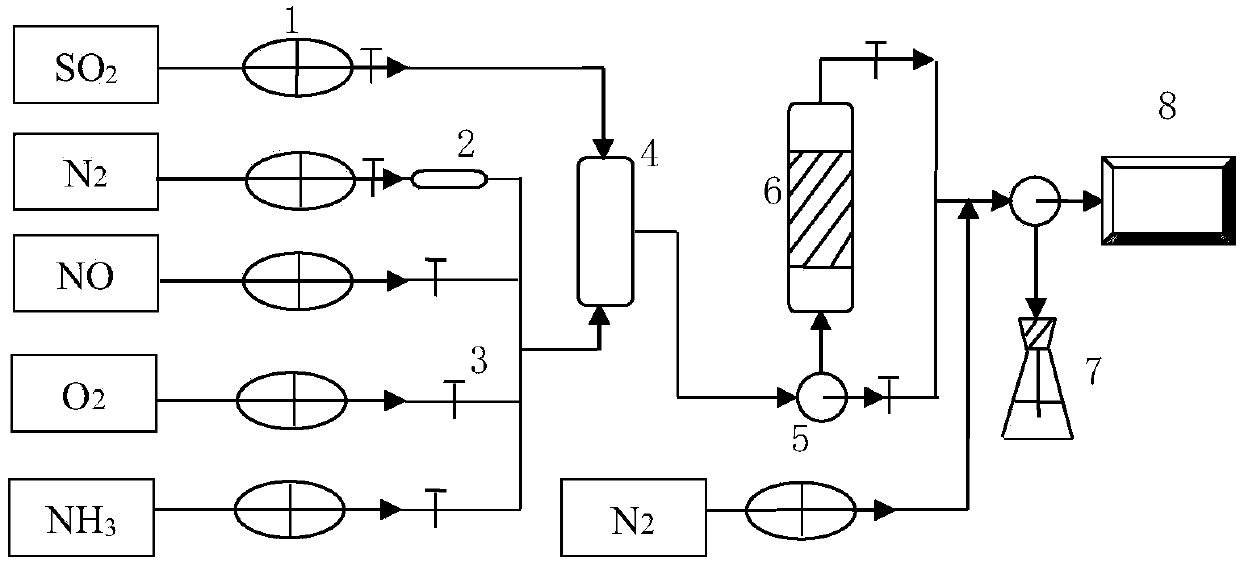

[0030] Embodiment 2 Phosphotungstic acid rare earth gadolinium salt doped iron-based catalyst (NdPW 12 o 40 / Fe y o x(1:3) ) denitrification activity test

[0031] Catalytic activity was evaluated by figure 1 The device shown is complete. A fixed-bed reactor was used, and the catalyst was loaded into a quartz reaction tube with an inner diameter of 8 mm. Both ends were fixed with quartz wool, and placed in a tubular electric furnace to control the reaction temperature. The flue gas composition is simulated with cylinder gas, where NO x (NO+NO 2 ) concentration is 1050ppm, NH 3 The concentration is 1150ppm, O 2 The volume fraction is divided into 6%, and nitrogen is used as the balance gas. The total flow rate is 100ml / min, and the space velocity is 15000h -1 , each gas flow is controlled and regulated by a mass flow meter. NO and NO in the outlet gas 2 Content by TH-9905 type NO / NO 2 Analyzer determination. The reaction test temperature is in the range of 150-400...

Embodiment 3

[0033] Embodiment 3 Phosphotungstic acid rare earth europium salt doped iron-based catalyst (EuPW 12 o 40 / Fe y o x(1:3) ) denitrification activity test

[0034] Catalytic activity was evaluated by figure 1 The device shown is complete. NO in simulated flue gas x (NO+NO 2 ) concentration is 1050ppm, NH 3 The concentration is 1150ppm, O 2 The volume fraction is divided into 6%, and nitrogen is used as the balance gas. The total flow rate is 100ml / min, and the space velocity is 15000h -1 , The reaction test temperature is 150 ~ 400 ℃. The conversion rate of nitrogen oxides was 44.7%, 69.9%, 99.6%, 100%, 100% and 85.6% respectively when the bed temperature was 150°C, 200°C, 250°C, 300°C, 350°C and 400°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com