SCR flue gas denitration composite catalyst and preparation method thereof

A composite catalyst, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of easy pulverization of catalysts, poor wear resistance, etc. The effect of increased surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

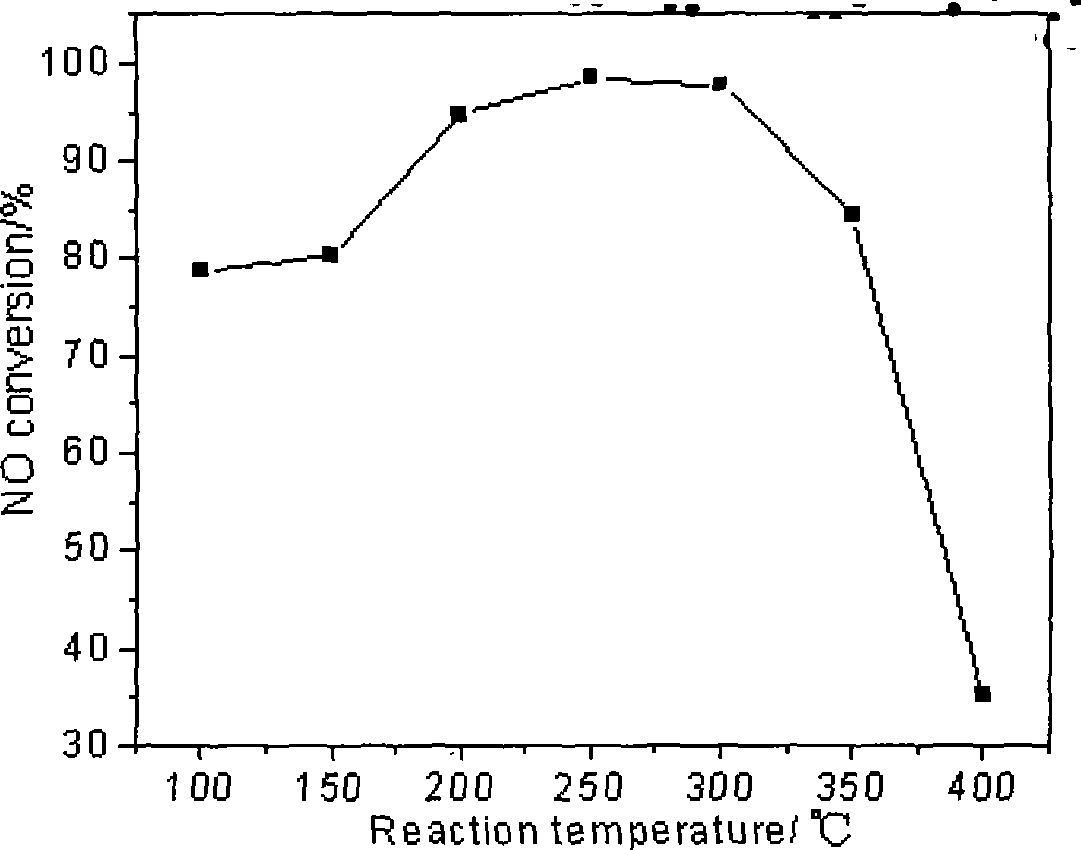

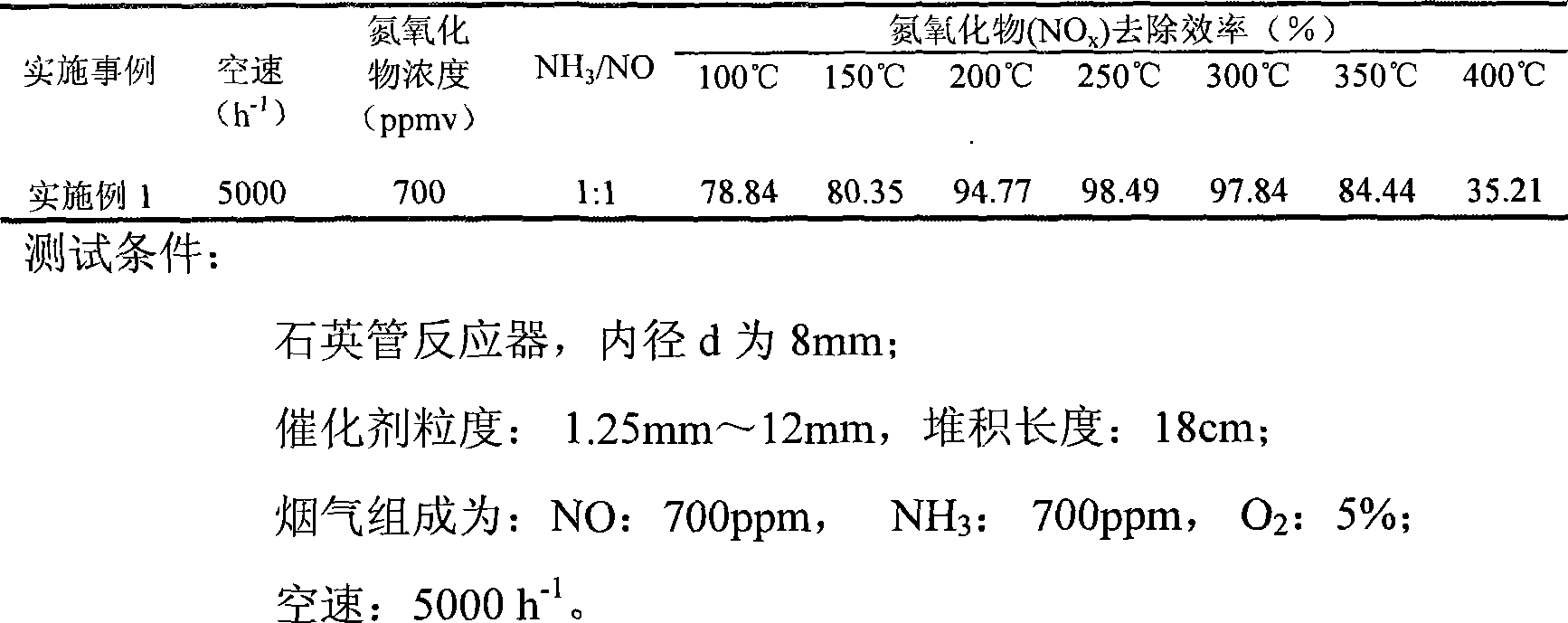

Examples

Embodiment 1

[0020] (1) TiO 2 -ZrO 2 -Al 2 o 3 -CeO 2 Composite sol preparation

[0021] First prepare liquid A with 17ml of butyl titanate and 25ml of absolute ethanol, then add 12ml of glacial acetic acid, 5ml of water, and 30ml of absolute ethanol in sequence to prepare liquid B, then add A dropwise into B, and stir for 20 minutes. Then add zirconium oxychloride and cerium nitrate and stir for 40 minutes according to the molar ratio of titanium, zirconium and cerium elements in a ratio of 3:1:2 to obtain a mixed sol of titanium, zirconium and cerium; dissolve 20g of pseudoboehmite powder in 285ml of Add about 10 g of 68% concentrated nitric acid dropwise to the deionized water while stirring, and then heat to 80° C., so that the pH value of the prepared sol is 0.5 and the relative density is 1.15. Finally, the aluminum sol was added into the titanium-zirconium-cerium mixed sol according to the molar ratio of the titanium-aluminum element being 3:1, and mixed and stirred for 40 minu...

Embodiment 2

[0026] (1) TiO 2 -ZrO 2 -Al 2 o 3 -CeO 2 Composite sol preparation

[0027] First prepare liquid A with 17ml of butyl titanate and 17ml of absolute ethanol, then add 12ml of glacial acetic acid, 5ml of water, and 38ml of absolute ethanol in sequence to prepare liquid B, then add A dropwise into B, and stir for 25 minutes. Then add zirconium oxychloride and cerium nitrate and stir for 30 minutes according to the molar ratio of titanium, zirconium and cerium elements of 1:0.5:0.5 to obtain a mixed sol of titanium, zirconium and cerium; dissolve 20g of pseudoboehmite powder in 285ml of Add about 10 g of 68% concentrated nitric acid dropwise to the deionized water while stirring, and then heat to 70° C., so that the pH value of the prepared sol is 1.1 and the relative density is 1.16. Finally, the aluminum sol was added into the titanium-zirconium-cerium mixed sol according to the molar ratio of the titanium-aluminum element being 2:1, and mixed and stirred for 30 minutes to ...

Embodiment 3

[0031] (1) TiO 2 -ZrO 2 -Al 2 o 3 -CeO 2 Composite sol preparation

[0032] First prepare liquid A with 17ml of butyl titanate and 34ml of absolute ethanol, then add 12ml of glacial acetic acid, 5ml of water, and 25ml of absolute ethanol in sequence to prepare liquid B, then add A dropwise into B, and stir for 25 minutes. Then add zirconium oxychloride and cerium nitrate and stir for 50 minutes according to the molar ratio of titanium, zirconium and cerium elements in a ratio of 1:1:2 to obtain a mixed sol of titanium, zirconium and cerium; dissolve 20g of pseudoboehmite powder in 285ml of Add about 8.9 g of concentrated nitric acid with a concentration of 68% dropwise to the deionized water while stirring, and then heat to 80° C., so that the pH value of the prepared sol is 1.5 and the relative density is 1.17. Finally, the aluminum sol was added into the titanium-zirconium-cerium mixed sol according to the molar ratio of the titanium-aluminum element being 1:2, and mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com