Electric drive jet engine

A jet engine and electric drive technology, applied in the field of aero-engines, can solve the problem of not being able to start by itself, and achieve the effects of increasing the lifespan, reducing the difficulty of production and increasing the voyage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

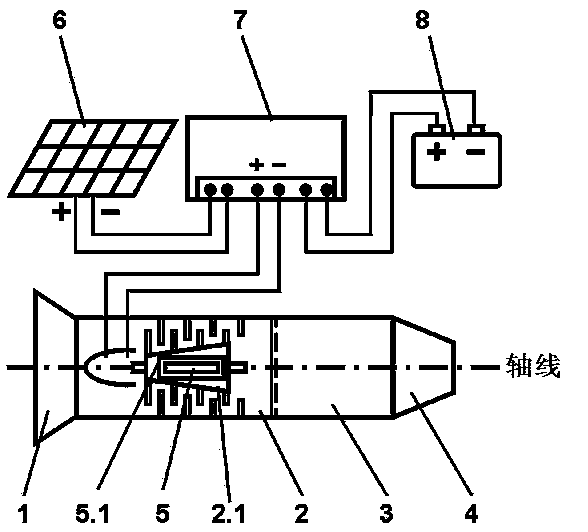

[0019] The following is attached with the manual figure 1 The present invention is further described.

[0020] Such as figure 1 , the electrically driven jet engine comprises an air inlet (1), a compressor (2), a combustion chamber (3), a propulsion nozzle (4), and a power supply system. An electric motor (5) is installed in the compressor (2), and the motor rotor (5.1) is coaxial with the compressor rotor (2.1). The power supply system is used to provide electric energy to the motor (5), and the motor (5) is used to completely drive the compressor (2). The so-called full drive means that the compressor (2) only needs the motor (5) as the only The power source does not need a turbine or other power source to drive. The air inlet (1) is used to inhale air, the compressor (2) is used to compress air, the combustion chamber (3) is used to mix and burn air and fuel, and the propulsion nozzle (4) is used to It is used to eject high-temperature gas and generate reaction force. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com