Spraying self-propelled multi-branch slim-hole completing tool and operation method

A multi-branch, self-propelled technology, applied in wellbore/well components, liquid/gas jet drilling, drilling equipment and methods, etc., can solve the problem of long operating time of radial drilling technology and uncontrollable fractures of fracturing technology , acidification technology to deal with problems such as small radius, to achieve the effect of simple and reliable construction operation, simple structure, safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

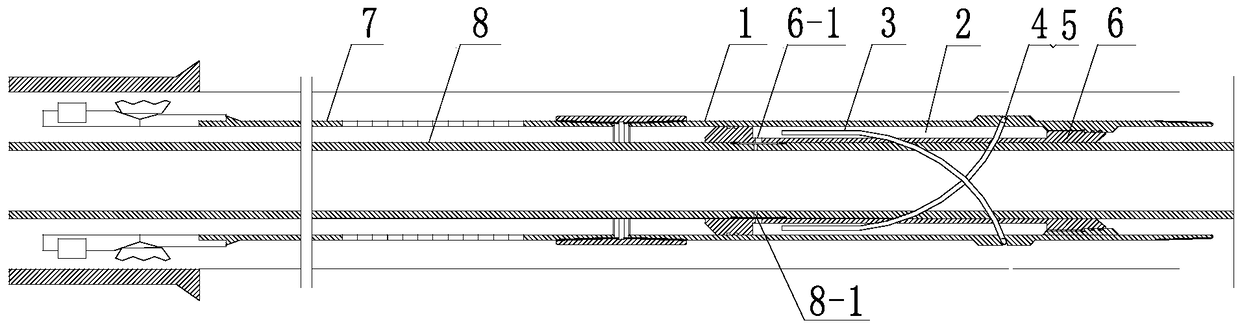

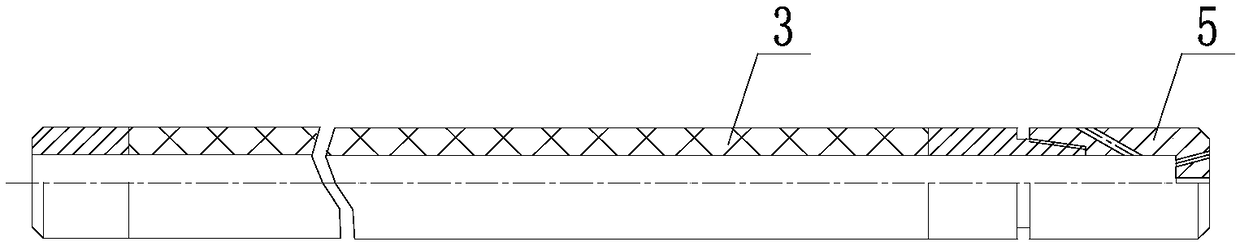

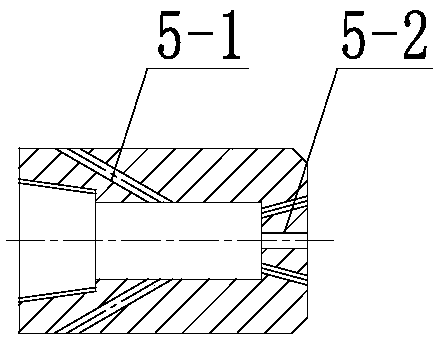

[0018] see Figure 1 ~ Figure 3 , a jet self-advancing multi-branch slim hole completion tool, comprising a jet sub-joint 1 connected to the lower end of the completion string, inside the jet sub-joint 1 is provided a liner 6 sealingly connected with it, the liner 6 Inside the injection sub-joint 1, the two are connected by threads, and an annular space 2 sealed up and down is formed between the liner 6 and the injection sub-joint 1, and the liner 6 is provided with The pressure transmission hole 6-1 communicating with the annular space 2 is provided with a plurality of branch thin pipelines 3 evenly distributed along the circumferential direction in the annular space 2, and the inlets of the branch thin pipelines 3 are arranged in the ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com