External combustion propelling engine

A technology of engines and propulsion nozzles, which is applied in the direction of machines/engines, jet propulsion devices, etc., and can solve the problems of difficulty and high cost of engine manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

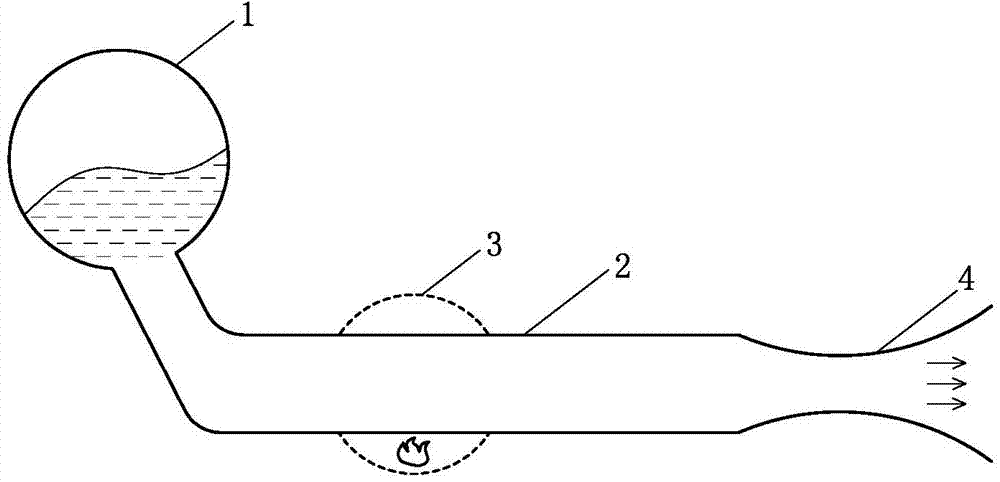

Embodiment 1

[0069] Such as figure 1 The external combustion propulsion engine shown includes a liquid working medium pressurized storage tank 1, a working medium heating fluid channel 2, a combustion chamber 3 and a propulsion nozzle 4, and the pressure bearing capacity of the liquid working medium pressurized storage tank 1 is greater than 2 MPa , the combustion chamber 3 is arranged for heat transfer to the working medium heating fluid passage 2, the working medium heating fluid passage 2 communicates with the propulsion nozzle 4, and the propulsion nozzle 4 outputs power externally, and the liquid working fluid The medium pressure storage tank 1 is in artesian communication with the working fluid heating fluid channel 2 .

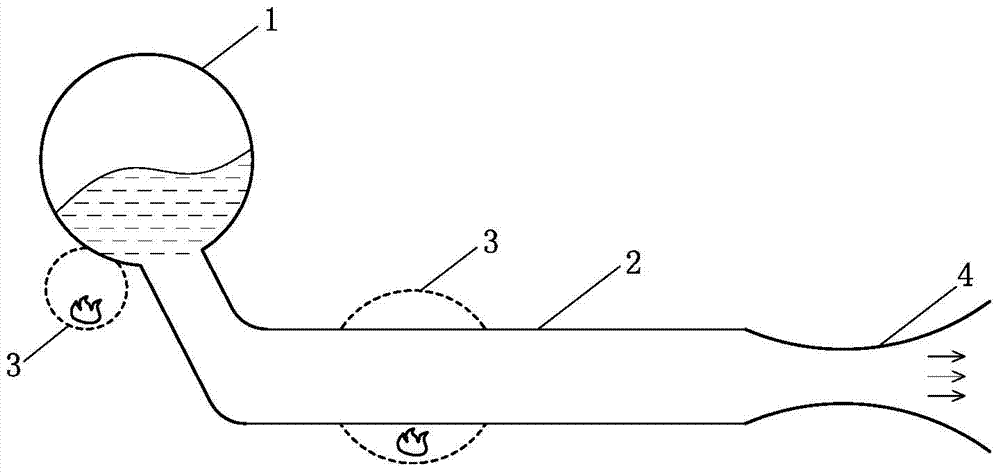

Embodiment 2

[0071] Such as figure 2 The difference between the external combustion propulsion engine shown in Embodiment 1 is that: the liquid working medium pressurized storage tank 1 is in artesian communication with the working medium heating fluid passage 2, and the combustion chamber 3 is connected to the liquid working medium The pressure storage tank 1 conducts heat.

[0072] As a changeable embodiment, it is also possible to make the liquid working medium pressurized storage tank 1 communicate with the working medium heating fluid passage 2, and the combustion chamber 3 transmits the pressure to the liquid working medium pressurized storage tank 1. hot.

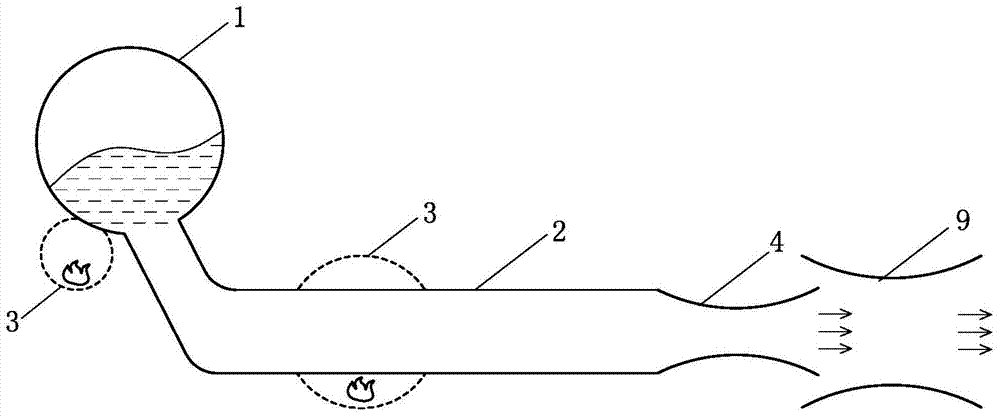

Embodiment 3

[0074] Such as image 3The external combustion propulsion engine shown, on the basis of Embodiment 2, further includes a jet pump 9 , and the working medium outlet of the propulsion nozzle 4 communicates with the motive fluid inlet of the jet pump 9 .

[0075] As a changeable implementation manner, the jet pump 9 can be set selectively on the basis of Embodiment 1 and the implementation manner obtained by transformation based on Embodiment 2 with reference to this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure endurance | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com