Cut-in direct-rotation mixed jet self-propelled nozzle

A self-propelled, jet technology, applied in the direction of drilling with liquid/gas jets, etc., can solve the problems such as the inability of the nozzle to move forward, the uneven bottom of the hole, etc., to enhance the shear and tensile damage effect, prevent energy loss, The effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

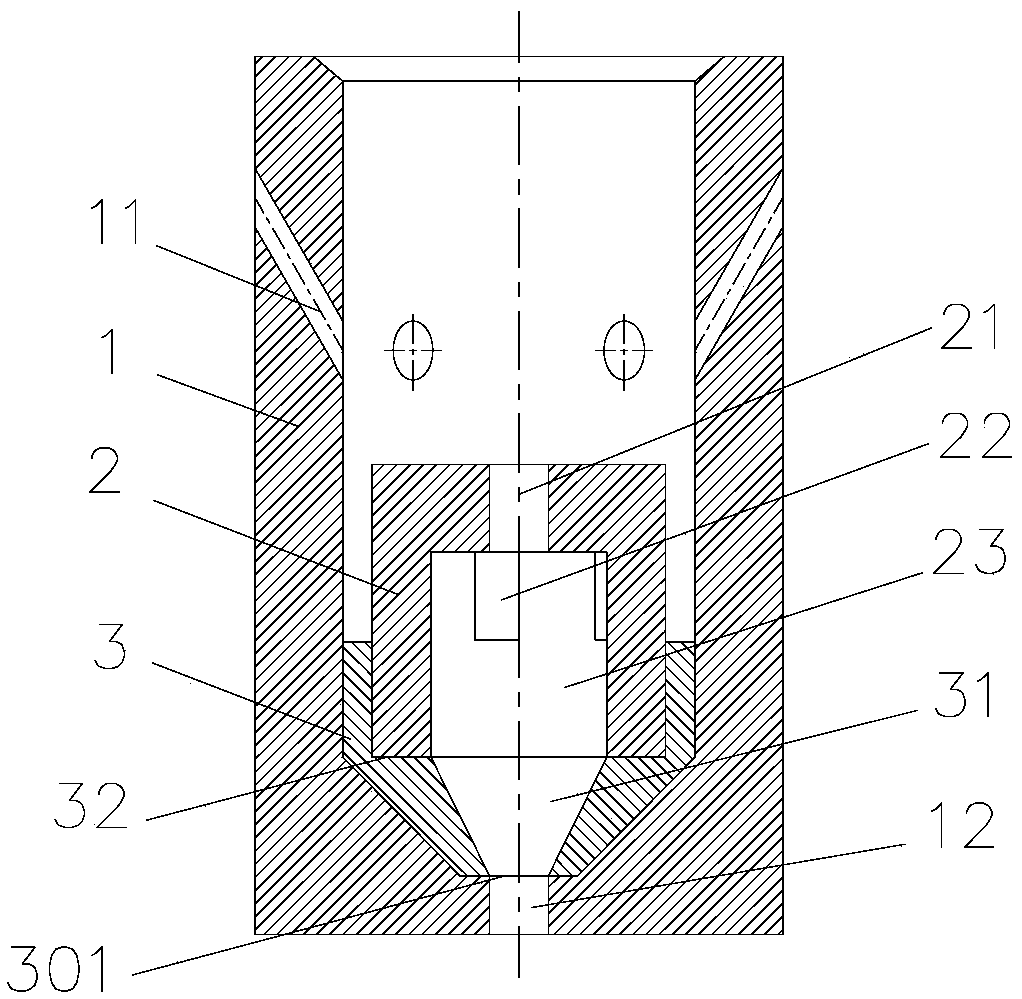

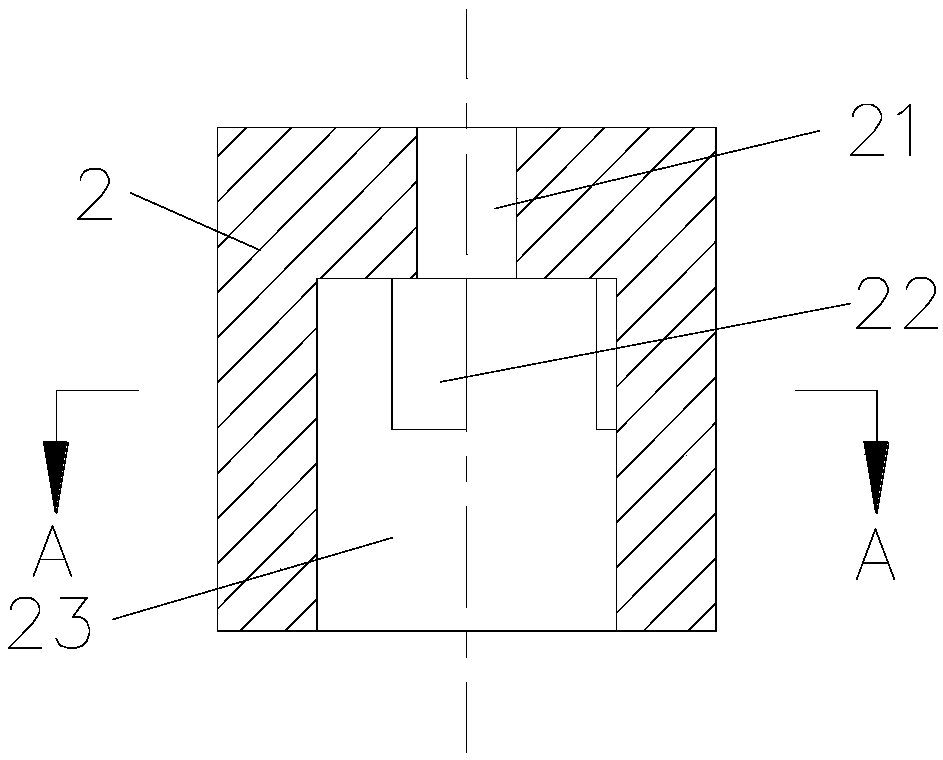

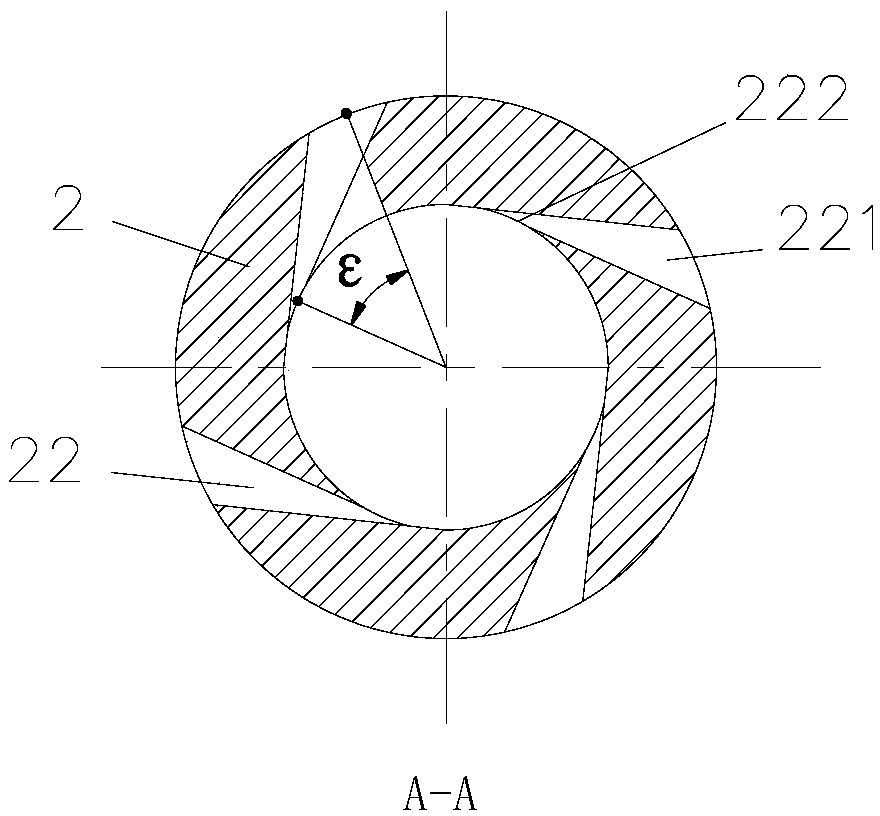

[0047] An embodiment of the present invention provides a cut-in direct-rotating mixed-jet self-advancing nozzle. see Figure 1-4 , the nozzle is composed of a mixed fluid 2, a mixed fluid seat 3, and a nozzle housing 1. The mixing body 2 is provided with a central hole 21 , a mixing chamber 23 and four cut-in grooves 22 . The central hole 21 is used to form a straight jet flow in the mixed flow chamber 23 , and the cut-in groove 22 forms a swirling jet flow in the mixed flow chamber 23 . The nozzle also includes a mixed fluid seat 3, on which a receiving groove 32 and a fluid channel 31 are arranged. The nozzle also includes a nozzle housing 1, and the nozzle housing 1 is provided with a rear nozzle 11 and a front nozzle 12. The mixed fluid 2, the mixed fluid seat 3, and the nozzle housing 1 are fixedly connected by means of interference fit.

[0048] In this example, the shape of the cutout 221 and the cutout 222 of the groove 22 is rectangular, and the shape and size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com