Supersonic non-uniform incoming flow maximum thrust nozzle and its wall surface determination method

A technology that determines the maximum thrust and method, and is applied to jet propulsion devices, machines/engines, etc. to achieve the effect of increasing thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

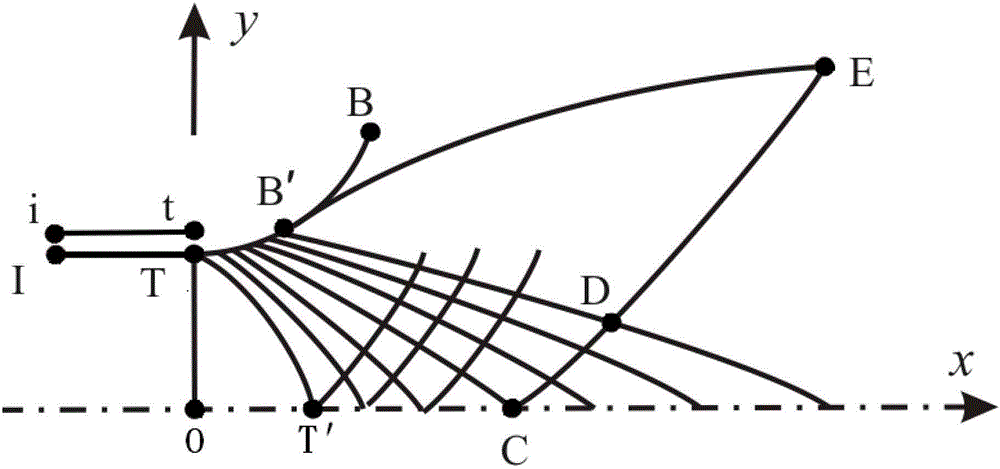

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0038] According to an embodiment of the present invention, the wall surface of the supersonic non-uniform incoming flow maximum thrust nozzle is determined by the following determination method.

[0039] combine figure 1 with figure 2 As shown, first, go to step S1: determine the initial boundary of the supersonic non-uniform incoming flow maximum thrust nozzle according to the non-uniform incoming flow parameters. Specifically, the non-uniform incoming flow parameters at the nozzle inlet are determined by numerical simulation or experimental measurement, where the incoming flow parameters include flow angle, velocity, temperature and pressure. These four parameters can be expressed by the function of coordinate y in turn: θ=θ(y), V=V(y), T=T(y)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com