Method for mixing a liquid in a sealed container with a fine-particle solid, container of this type, ejector jet and use of a jet of this type

A technique for injectors, liquids, for mixing liquids in closed containers with fine-grained solids, such containers, injector nozzles and fields of application of such nozzles, capable of solving problems that are not fully satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

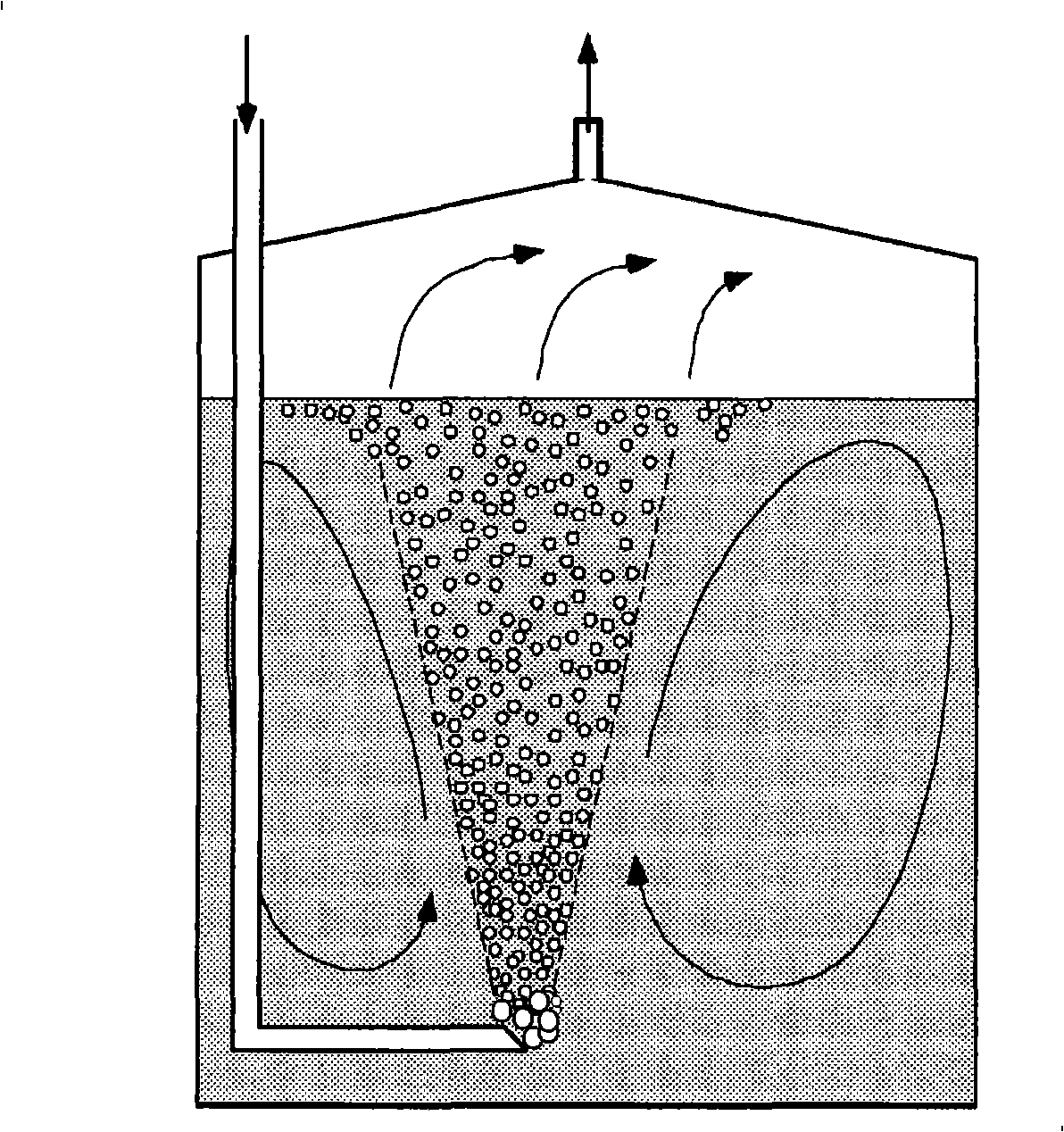

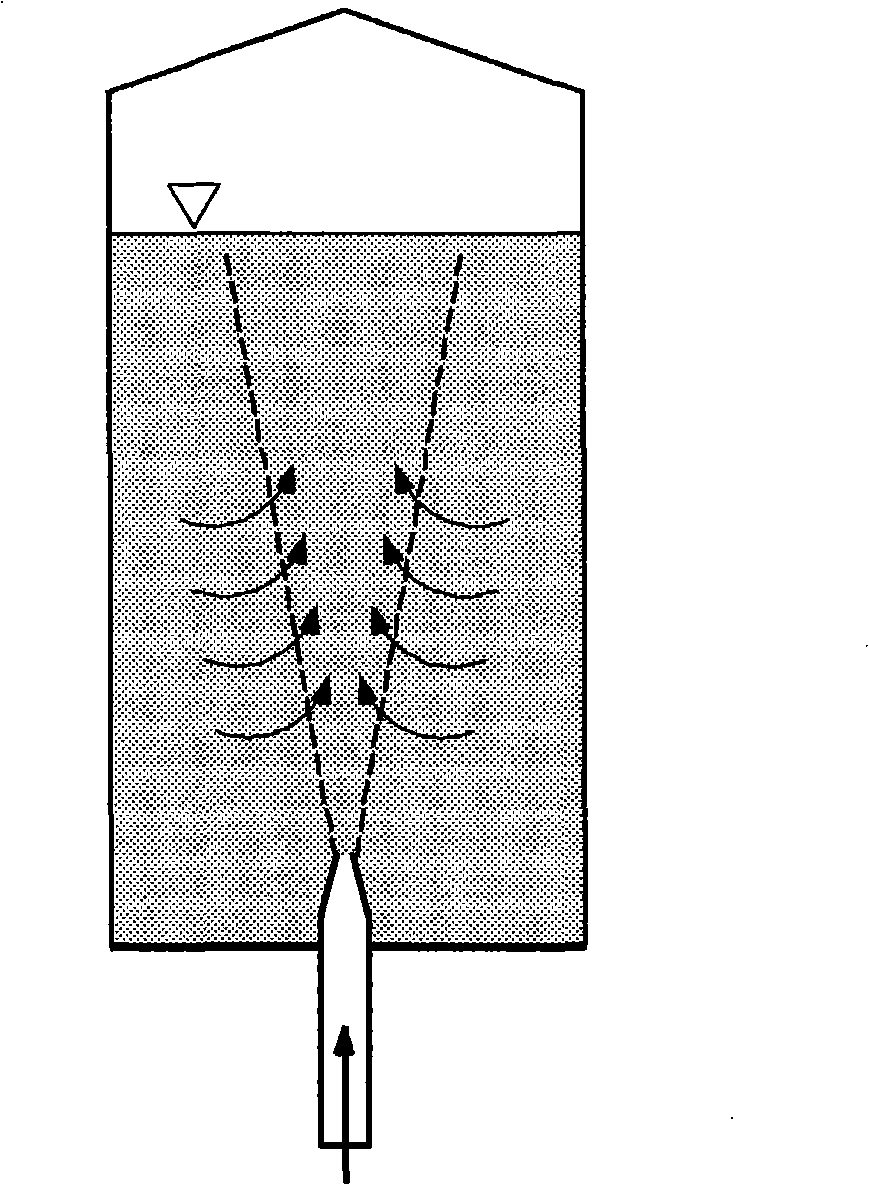

[0071] 1. A method of mixing a liquid or a mixture of liquid and fine-grained solids present in a substantially closed container, with the proviso that the liquid or mixture fills only a part of the internal volume of the container that the fluid phase can occupy, and the rest of the container The occupiable internal volume is filled by a gas phase, the method comprising supplying substantially the same liquid or substantially the same mixture into the container in the form of a powered jet of a suction device arranged in the liquid or in the mixture of the container, wherein the suction device is provided by means of The powered jet draws gas from the gas phase present in the container and releases the sucked gas together with the powered jet into the liquid or mixture present in the container.

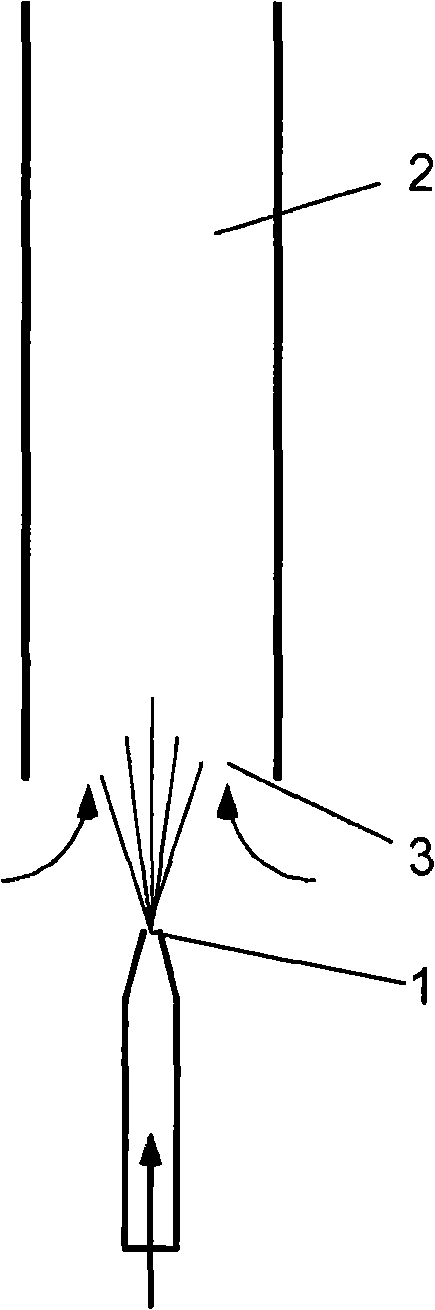

[0072] 2. The method according to embodiment 1, wherein the suction device comprises at least one injector having a powered nozzle and a suction chamber connected to the gas phase (vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com