Fuel delivery device

A technology of oil transportation and fuel oil, applied in the direction of power plant, transportation and packaging, charging system, etc., can solve the problems of high manufacturing cost and special structure, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

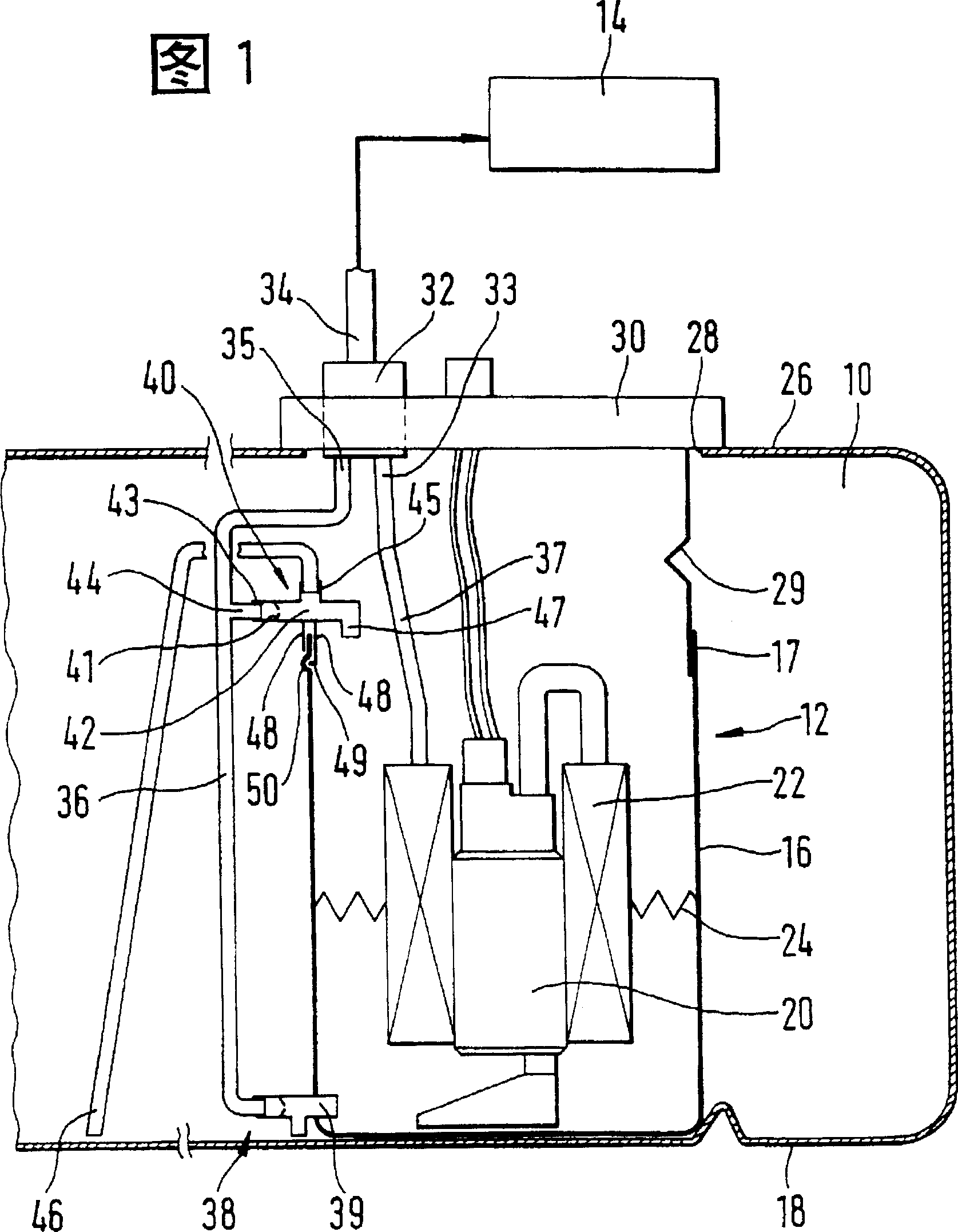

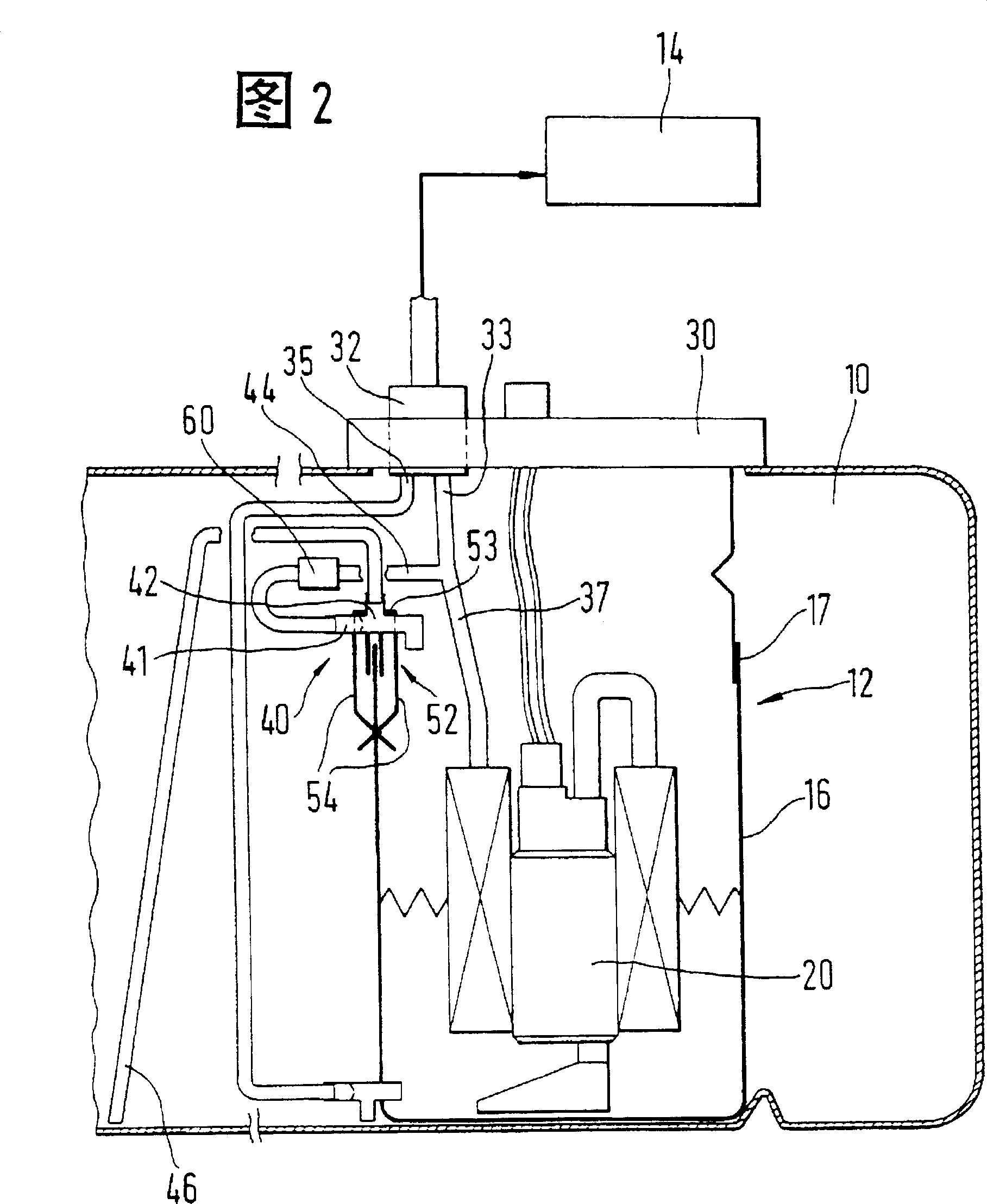

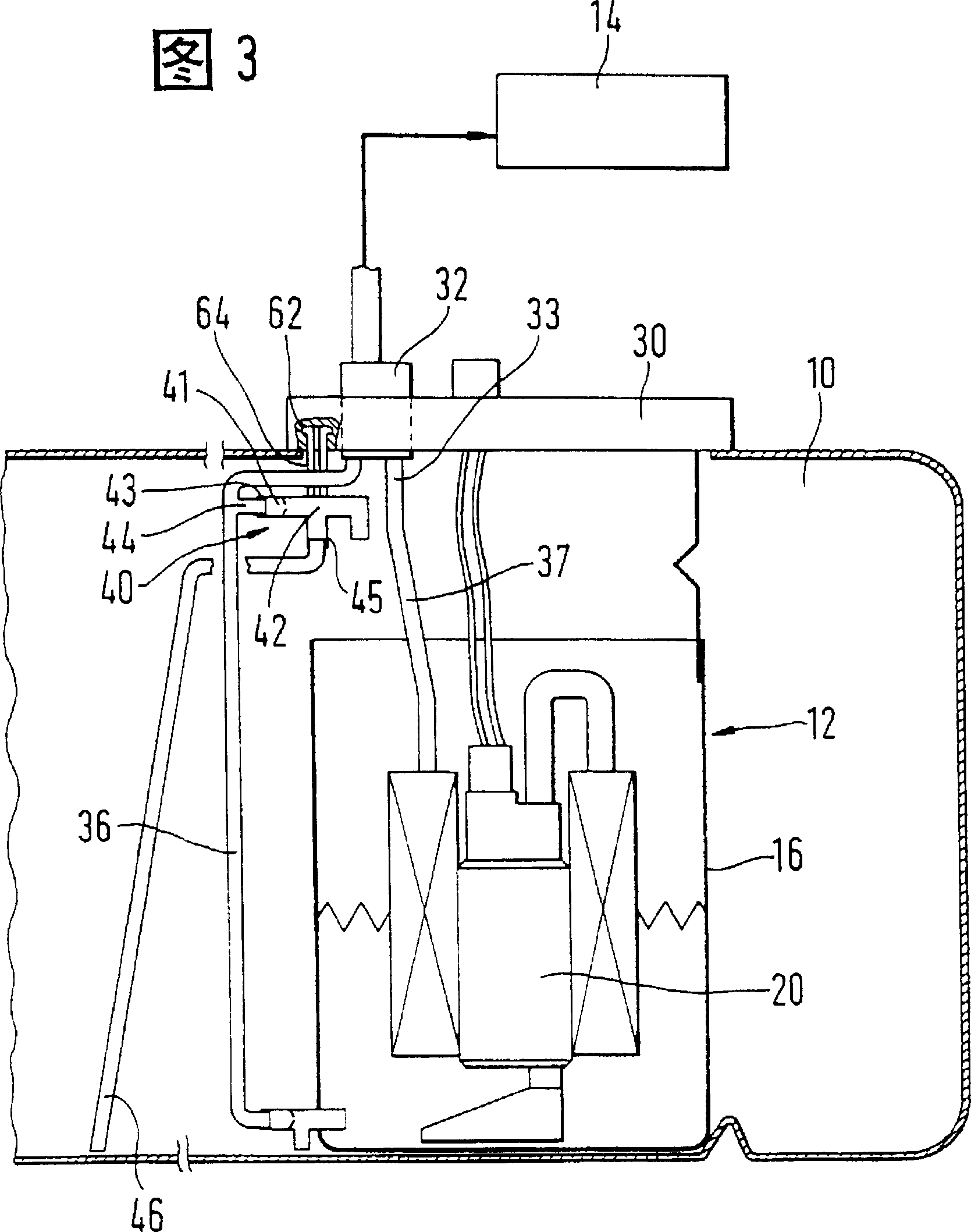

[0014] FIGS. 1 to 3 partially show a fuel reserve tank 10 of a motor vehicle, in which a delivery device 12 for feeding fuel from the reserve tank 10 to a fuel injection system of an internal combustion engine 14 of the motor vehicle is installed. The oil delivery device 12 has a pot-shaped container 16 which can be placed on the bottom 18 of the reserve oil tank 10 and fastened to the bottom 18 in a manner not shown. The container 16 can be made, for example, of oil-resistant plastic and is open at its upper end. A fuel delivery unit 20 is inserted into the container 16 , from which fuel is sucked in during operation of the unit and delivered to the internal combustion engine 14 . The fuel delivery unit 20 has a pump part and a motor part that drives it, in particular a drive motor. Furthermore, a filter 22 can be installed in the container 16 , by which the fuel delivered by the delivery unit 20 is filtered before it is delivered to the internal combustion engine 14 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com