Self-advancing and retreating type jet flow drill bit and drilling method

An advance and retreat, drill bit technology, which is used in drilling with liquid/gas jets, production of fluids, earth-moving drilling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

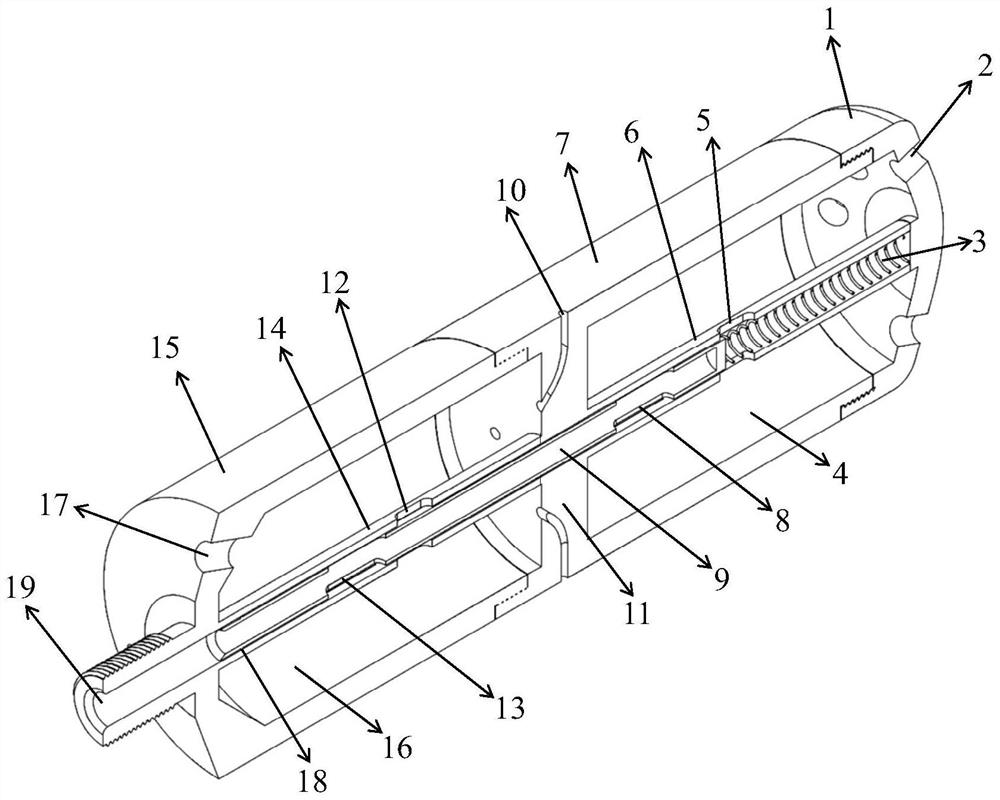

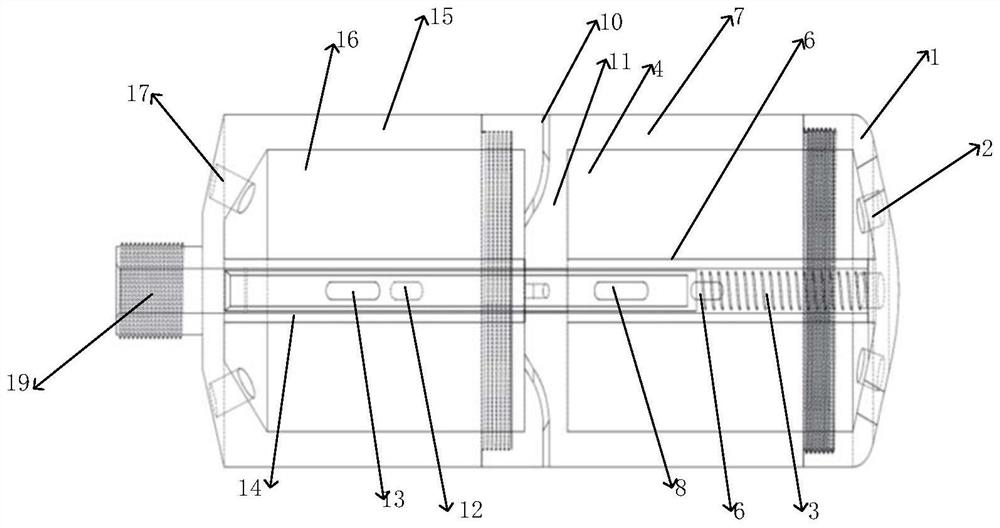

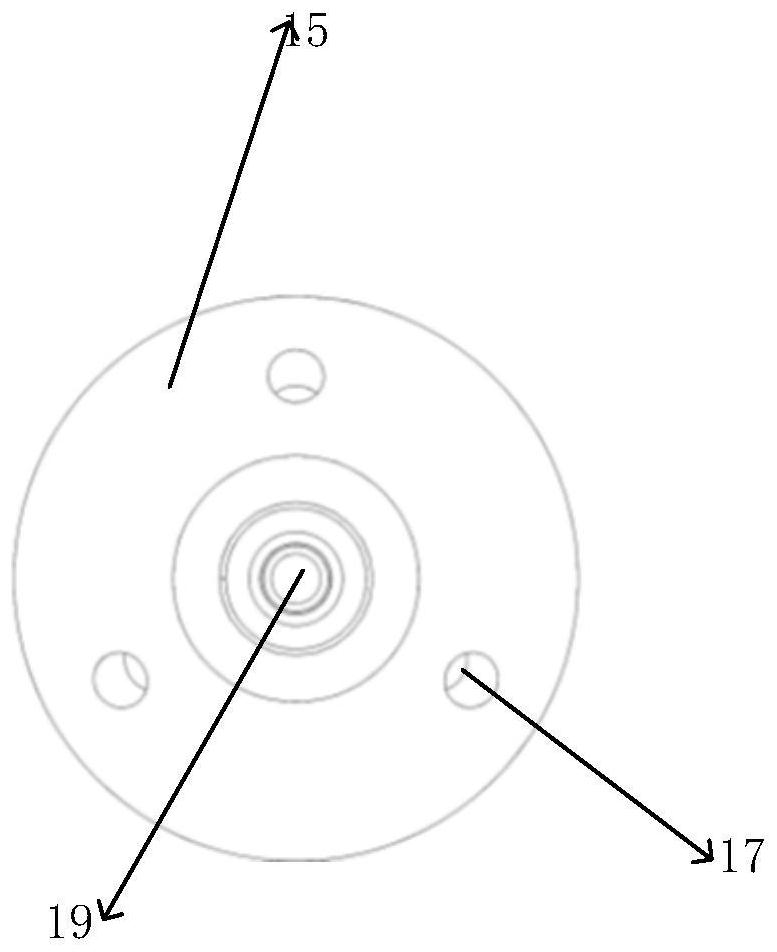

[0044] The present invention will be further described below in conjunction with accompanying drawing:

[0045] refer to Figure 1 to Figure 7 , a self-advancing and retreating jet drill bit is provided in this embodiment, which mainly includes a drill bit housing, and an independently arranged propulsion pressure-bearing chamber 16 and a coal-breaking pressure-bearing chamber 4 are formed inside the drill bit housing. A liquid inlet pipeline, the drill bit housing is provided with a drill bit liquid inlet 19 communicating with the liquid inlet pipeline, and the liquid inlet pipeline has a propulsion pressure chamber liquid inlet 12 communicating with the propulsion pressure chamber 14 and The coal-breaking pressure-bearing chamber liquid inlet 5 communicating with the coal-breaking pressure-bearing chamber 4; the propulsion nozzle 17 communicating with the propulsion pressure-bearing chamber 16 is also installed on the drill bit housing, and the coal-breaking bearing The coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com