Hydraulic jet grouting drill bit

A drill bit and hydraulic technology, applied in the field of petroleum exploration, can solve the problems of restricting the drilling efficiency and drilling depth of branch pipes, it is difficult to have a hollow structure with large power output, and it does not have the function of rotary drilling, etc., so as to improve drilling efficiency , Improve the drilling depth and the effect of flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention will be further described:

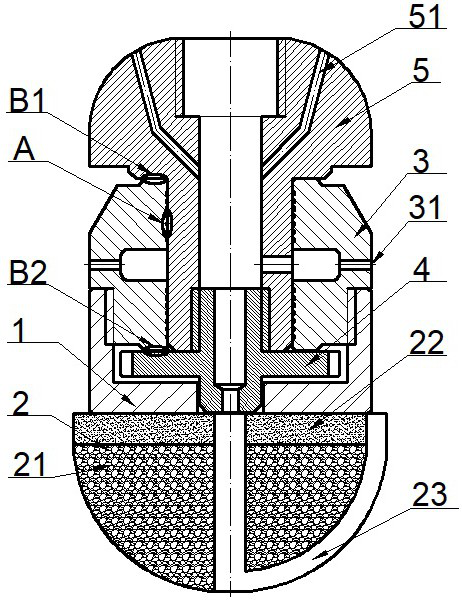

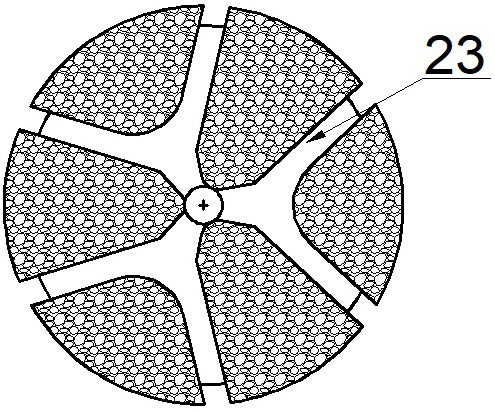

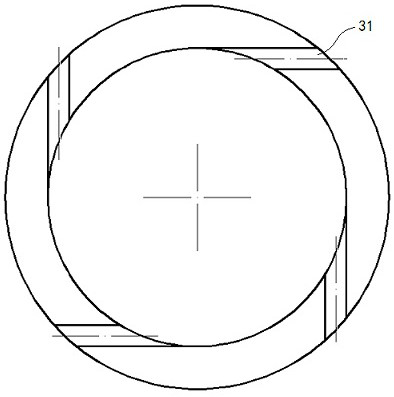

[0036] Figure 1 to Figure 5 It shows the first embodiment of a hydrodynamic rotary jet drill bit of the present invention. figure 1 , Figure 4 and Figure 5 It is a schematic diagram of the structure of the hydrojet drill bit in this embodiment; figure 2 It is a structural schematic diagram of cutting block in this embodiment; image 3 It is a schematic diagram of the arrangement of eccentric nozzles on the rotating body in this embodiment.

[0037] Such as figure 1 As shown, the hydrojet drill bit in this embodiment includes a drill steel body 1, a top wire 4 and a mandrel 5. One end of the drill steel body 1 is provided with a cutting tire block 2, and the other end is connected with the rotating body 3. The core One end of the shaft 5 passes through the hollow part of the rotating body 3 and is connected with the top wire 4. The top wire 4 is arranged in the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com