Accurate feed putting device based on stepping motors for poultry breeding

A stepping motor and precise feeding technology, which is applied in the field of precision feeding devices for poultry breeding, can solve the problems of inaccuracy, inaccurate feeding, and lower meat-to-feed ratio, and achieve the effect of high feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

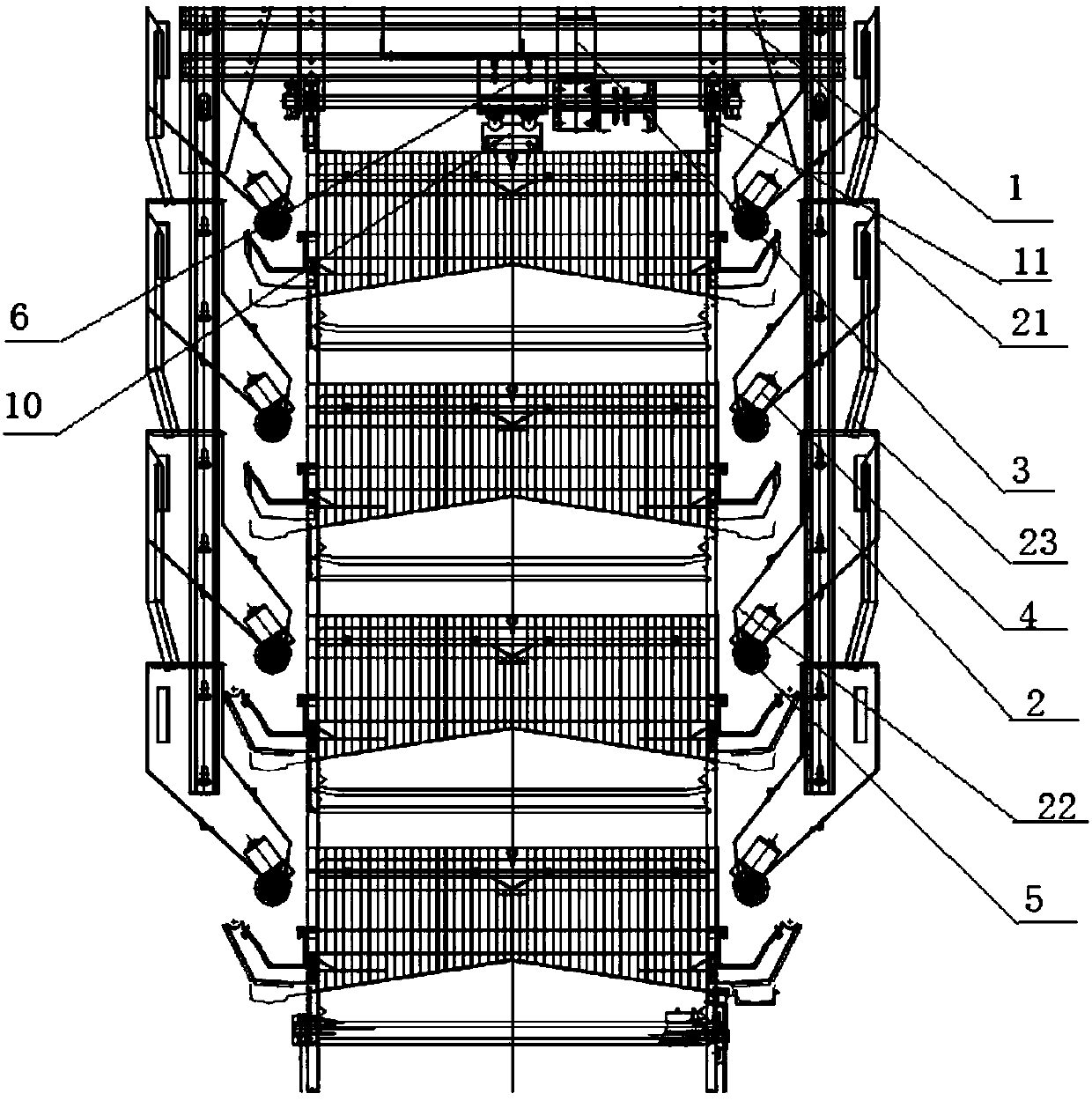

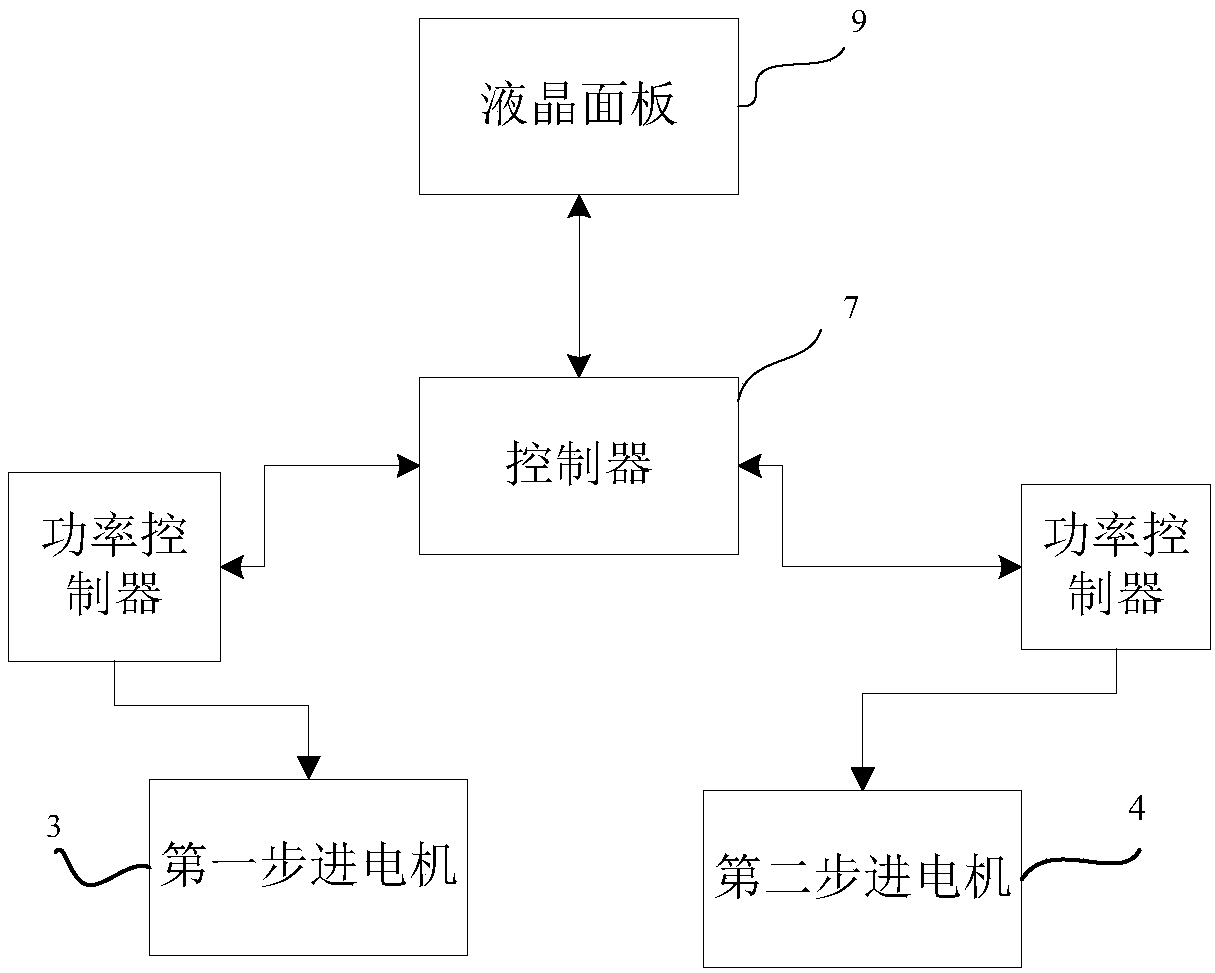

[0029] Such as Figure 1-5 As shown, a precision feeding device for poultry breeding based on a stepping motor includes a self-driven driving bracket 1 arranged on a poultry breeding pen, and two sides of the driving bracket 1 are provided with 4 layers to feed poultry troughs. The hopper 2 for internal feeding; the driving bracket 1 is driven by the first stepping motor 3 arranged on the driving bracket 1, and the outlet position of each hopper 2 is provided with a feed metering output controlled by the second stepping motor 4 mechanism.

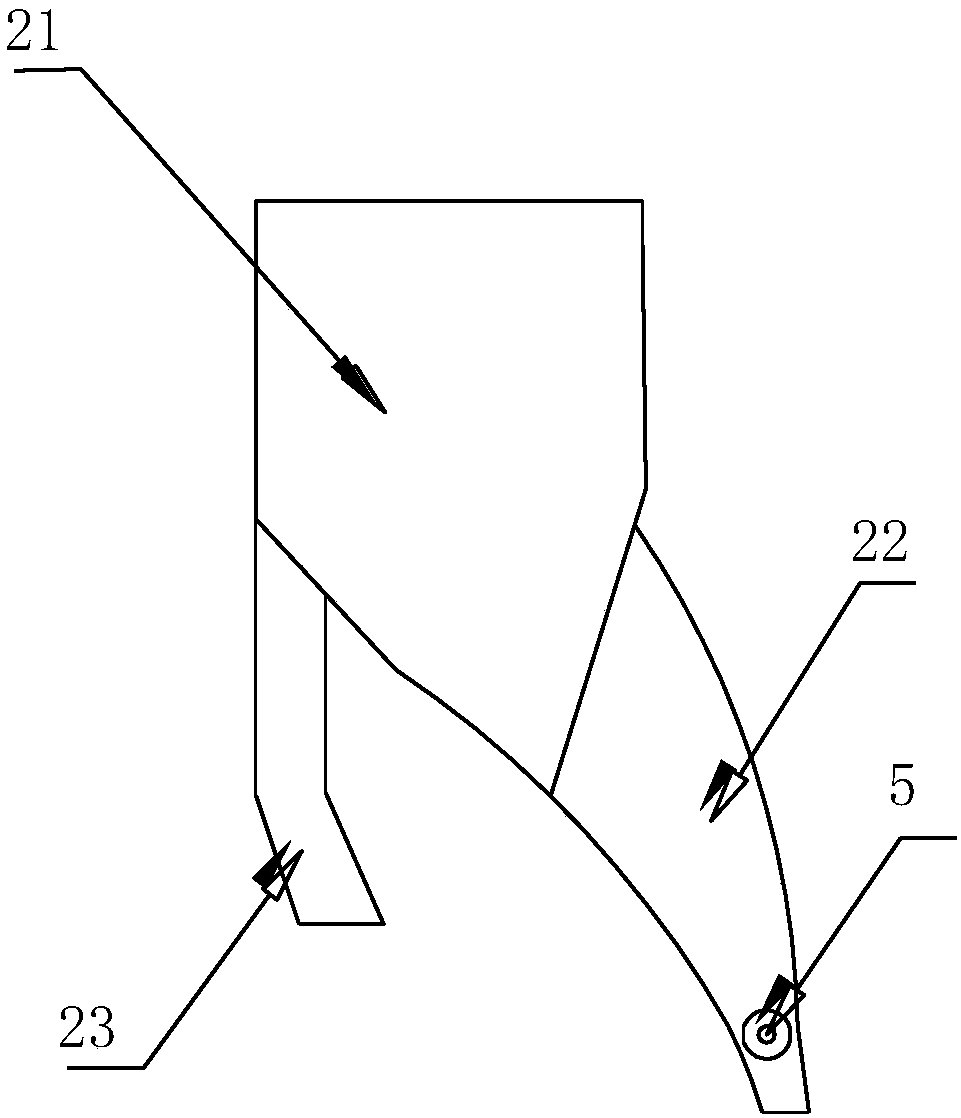

[0030] It should be noted that, in practical applications, the number of layers of the hopper 2 can be set freely, and it only needs to be consistent with the number of layers of the poultry breeding pen. The shape design of the hopper 2 is specifically as follows: comprising a hopper 21 and a hopper mouth 22, the outlet of the hopper 2 is arranged on the hopper mouth 22, and the hopper 2 above the lowermost hopper 2 is provided with a sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com