Unison feed device of industrial horizontal-cylinder unison-feed sewing machine

A feeding device and industrial technology, applied in the direction of sewing machine components, sewing machine needle seat, cloth feeding mechanism, etc., can solve the problems of not being able to meet high requirements, poor processing, and poor return sewing effect, so as to improve the return sewing effect, high Processing requirements, the effect of high feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

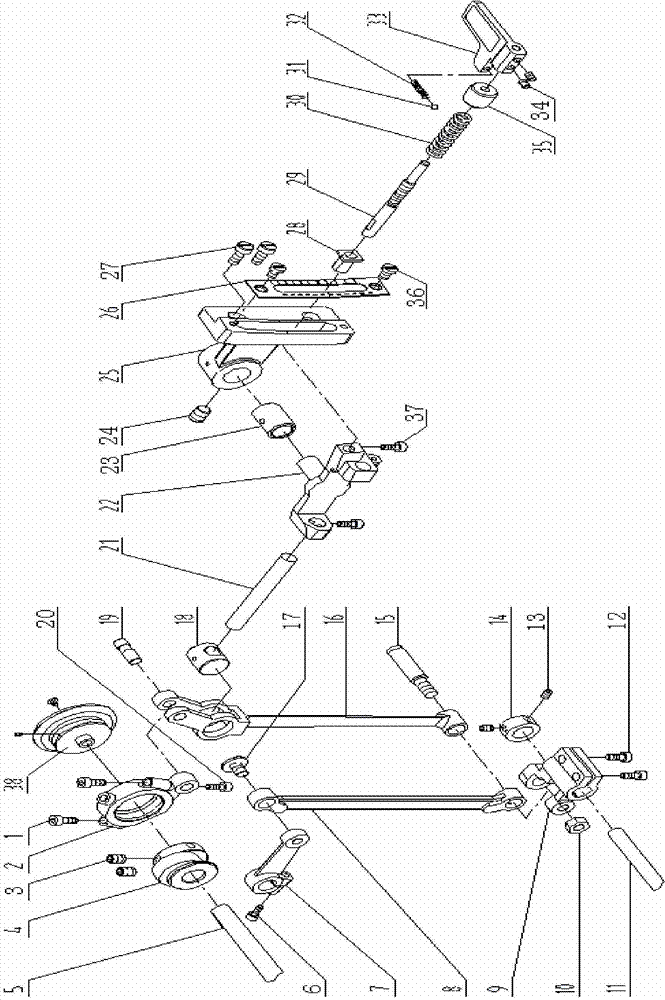

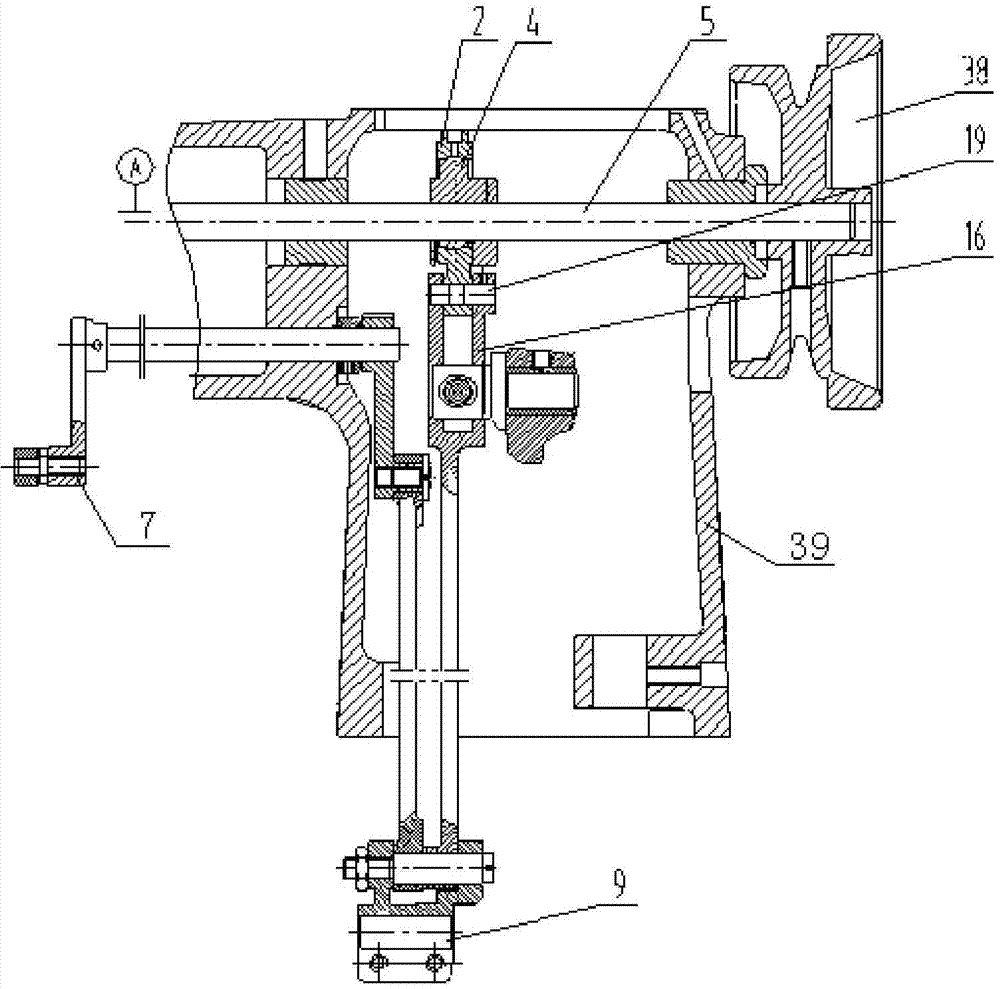

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0017] Such as figure 1 , figure 2 As shown, a specific embodiment of the present invention is provided. In the figure, it includes a casing 39, a belt pulley 38 connected to the power mechanism, a transmission mechanism, a feeding rocker group and a stitch adjustment device, and the belt pulley 38 is installed on the casing 39 side, the upper shaft 5 is connected with its transmission, the upper shaft 5 is equipped with a feeding eccentric cam 4 through a screw 3, and the feeding eccentric cam 4 is connected with a driving connecting rod 2, which is equipped with a fastening screw 1 and a driving connecting rod 2 Connect with the fork of the fork-shaped connecting rod 16 through the screw 20 and the crank pin 19;

[0018] A sliding sleeve 18 is installed at the plug of the fork-shaped connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com