Material distributor

A dispenser and material technology, which is applied to other washing machines, washing devices, laundry room devices, etc., can solve the problems of cumbersome manual operation and inaccurate dosage, and achieve the effects of high feeding accuracy, reduced workload, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

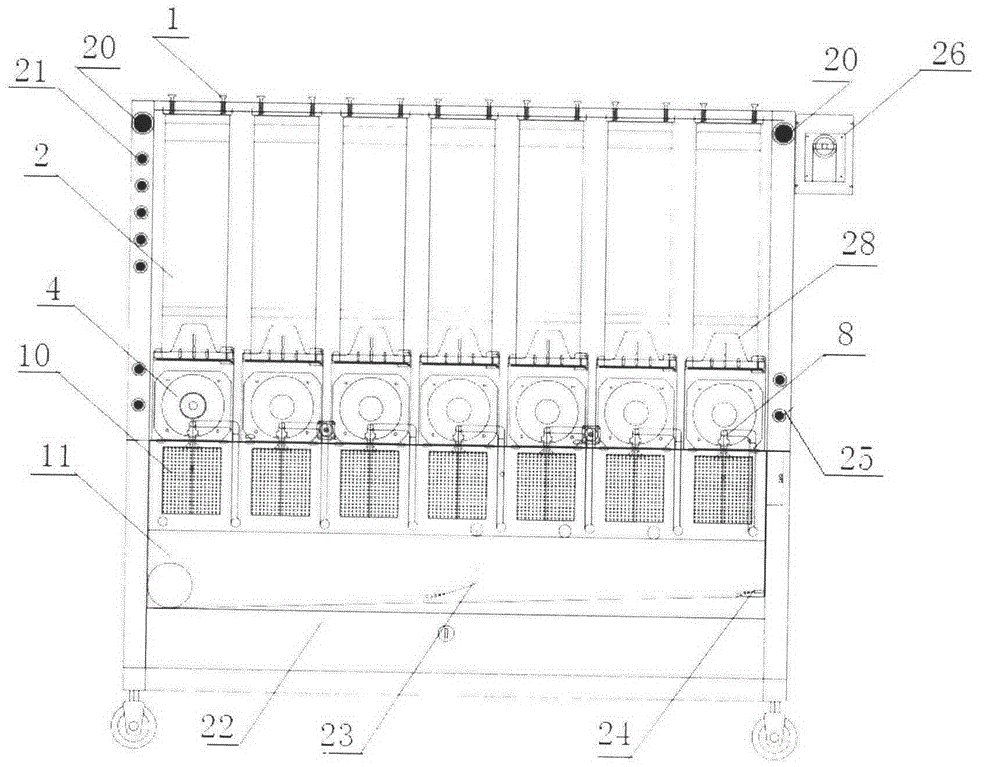

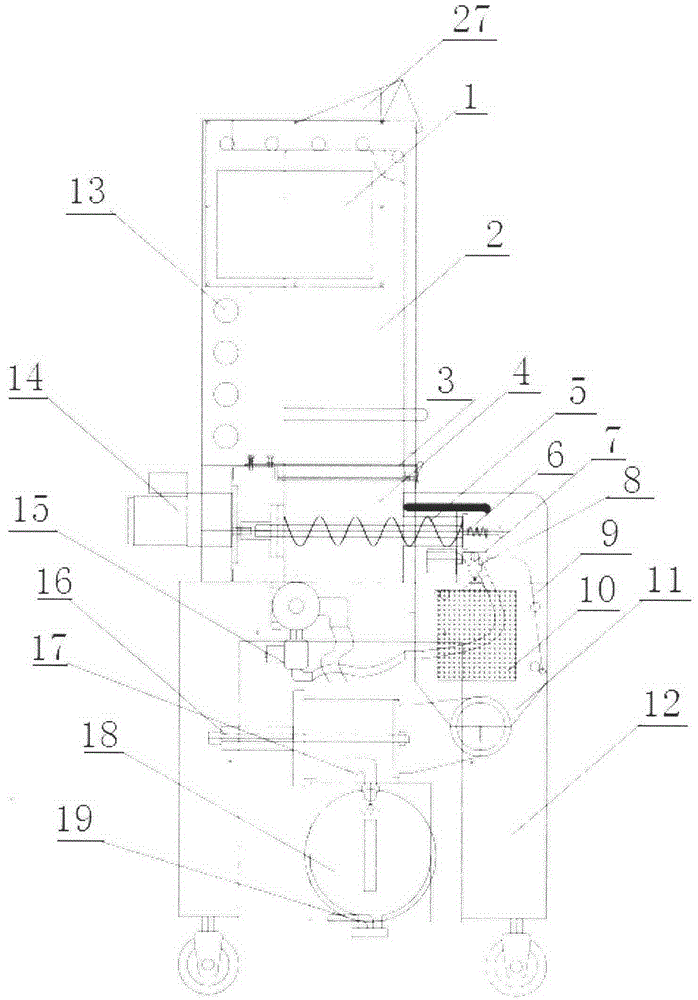

[0017] Reference Figure 1-Figure 2 The material dispenser of this embodiment is connected to the washing machine through a pipeline. It includes a fixing frame 12, a material barrel 2, an electric box control mechanism, a feeding device, a punching device, and a pump 18 all fixed on the fixing frame 12. The feeding device, the punching device, and the pump 18 are respectively connected to the electric box control mechanism. The material barrel 2 is arranged above the feeding device and connected to the feeding device. A punching device connected to the feeding device is provided below the feeding device. The punching device is arranged obliquely, and the outlet end of the punching device is set at a low place. The pump is set under the punching device. The bottom of the pump is connected to the washing machine through a pipe. A liquid peristaltic pump 26 is provided on the side of the fixing frame 12. Inhale liquid materials.

[0018] The material bucket 2 is set above the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com