Rotary spraying-flushing device lifted by water power

A hydraulic and ball-spraying technology, which is applied to spraying devices, spraying devices with movable outlets, cleaning hollow objects, etc., can solve the problems of incomplete cleaning of the inner wall of beverage bottles, limited water column height, and insufficient strength, etc., to achieve cleaning efficiency Excellent, compact structure, comprehensive flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

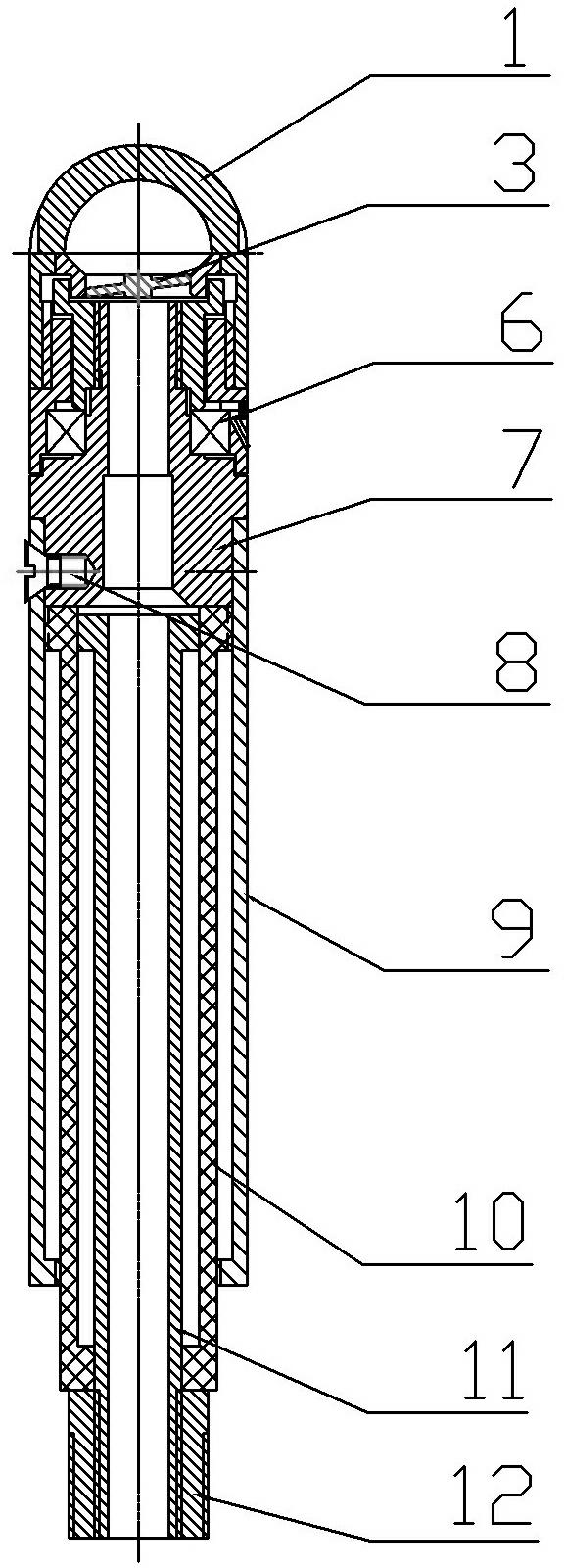

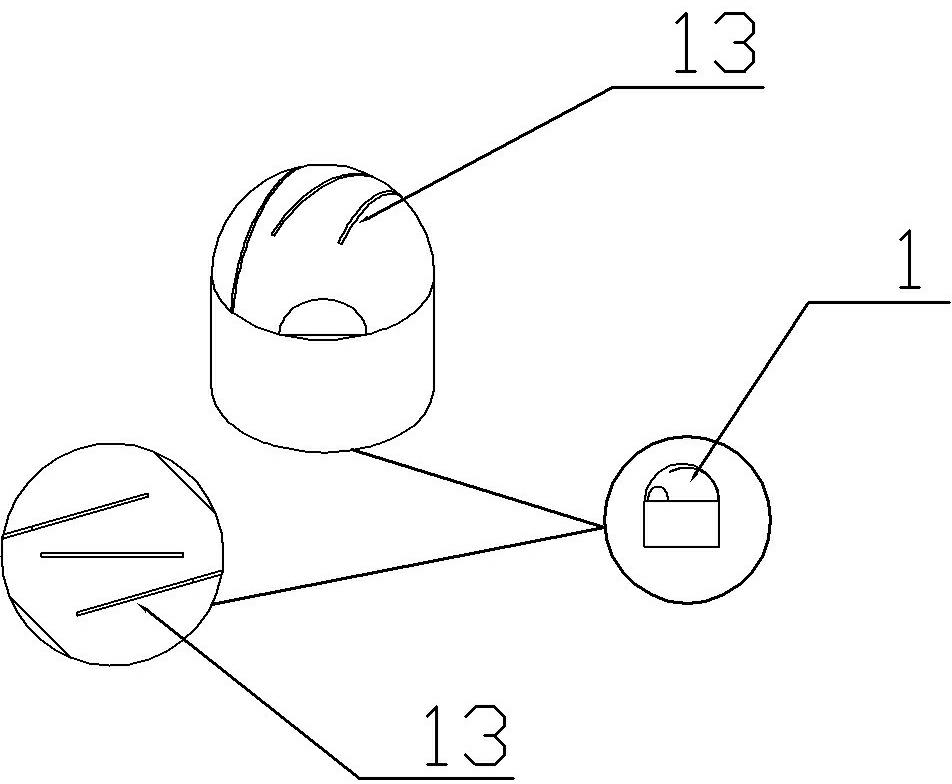

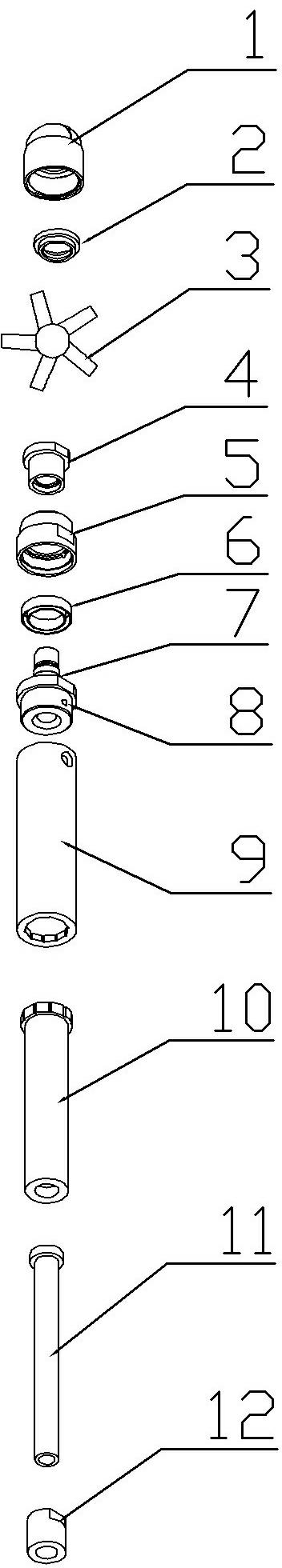

[0019] The structure of the hydraulic lifting rotary spraying device is as follows:

[0020] Such as figure 1 , 2 As shown, in the rotary spraying device, an inner slide 11 is connected with an external water pipe through a pipe joint 12 to transmit water for spraying, and a middle slide 10 is sleeved on the inner slide 11 and can be moved along the It slides up and down, a connecting seat 7 is fixedly set in the outer sliding cylinder 9 by screws 8, and its interior is hollow for water to flow through, a deep groove ball bearing 6 is set and fixed on the connecting seat 7, and the spray ball joint 5 is installed on the The outer side of the deep groove ball bearing 6 can freely rotate in the forward or reverse direction. The inside of the fixed joint is hollow, one end of which extends into the spray ball joint 5, and the other end is inserted into the rotating spray ball 1 and can guide the water introduced in the sliding cylinder to Spray from the rotating spray ball 1, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com