Side connection type high-pressure escape boat

A technology of high pressure and escape cabin, which is applied in the field of saturation diving safety lifesaving equipment, can solve the problems of reducing the overall strength of the lifeboat, increasing the resistance of the lifeboat, and affecting the escape efficiency, so as to avoid excessive resistance of the hull, improve survivability, and improve escape efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

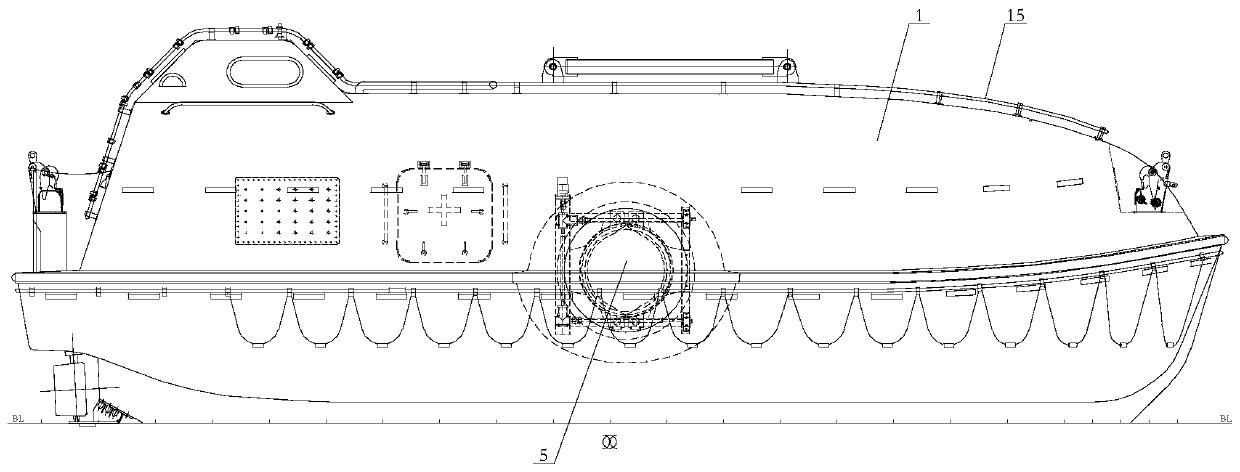

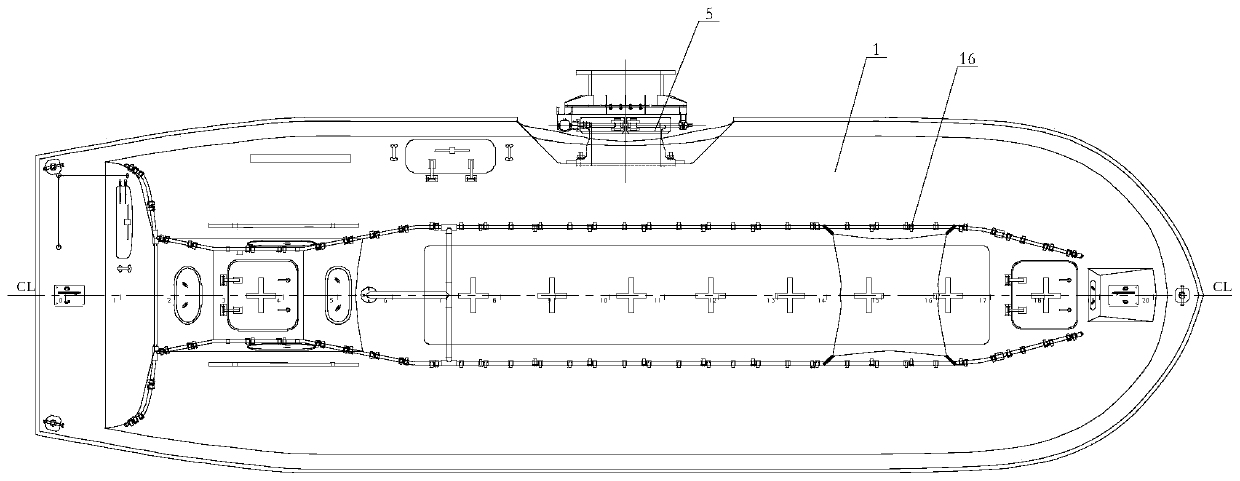

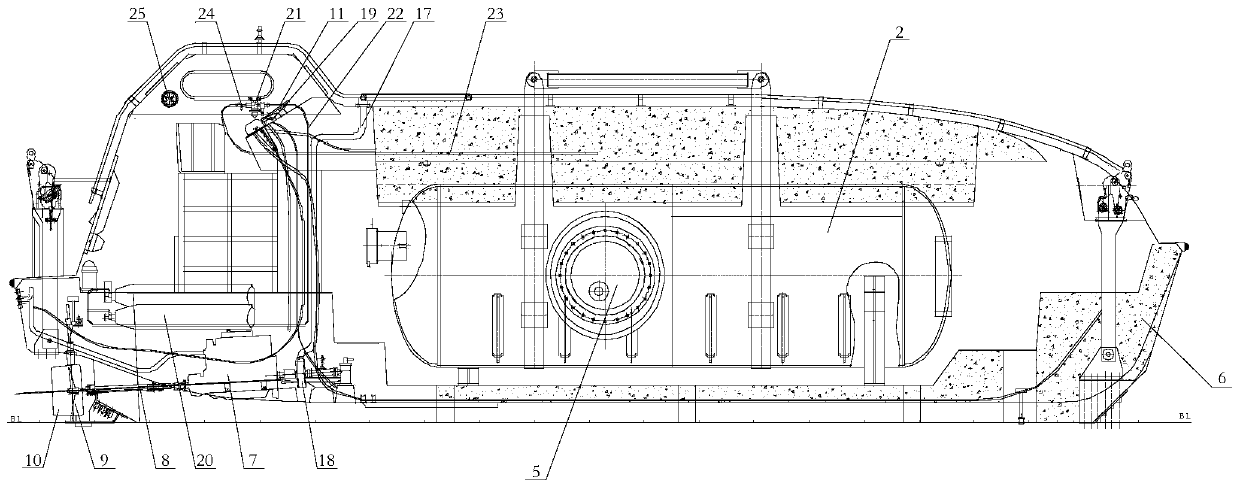

[0029] combine Figure 1 to Figure 6 As shown, the specific implementation of a side-mounted high-pressure escape boat provided by the present invention will be described.

[0030] A side-connected high-pressure escape boat, which is used in the emergency evacuation of divers during the decompression process. It integrates the side-connected escape cabin into the escape boat. The escape cabin has self-propelled capability, and the hull 1 is made of fire-resistant glass fiber reinforced plastic. Manufactured and equipped with other fire safety measures to facilitate the safe and rapid evacuation of divers who are decompressing.

[0031] The specific structure of the side-connected high-pressure escape boat is that a side-connected high-pressure escape cabin is installed in the hull 1 of the escape boat. The bow in the length direction is the front, the stern is the rear, and the length direction of the hull is the direction between the bow and the stern. The side-connected hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com