Preparation method of polyaniline nanometer fiber

A technology of nanofibers and polyaniline, applied in the field of preparation of polyaniline nanofibers, can solve the problems of limited electrode area, low synthesis output, expensive, etc., and achieve the effect of simple and easy operation, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

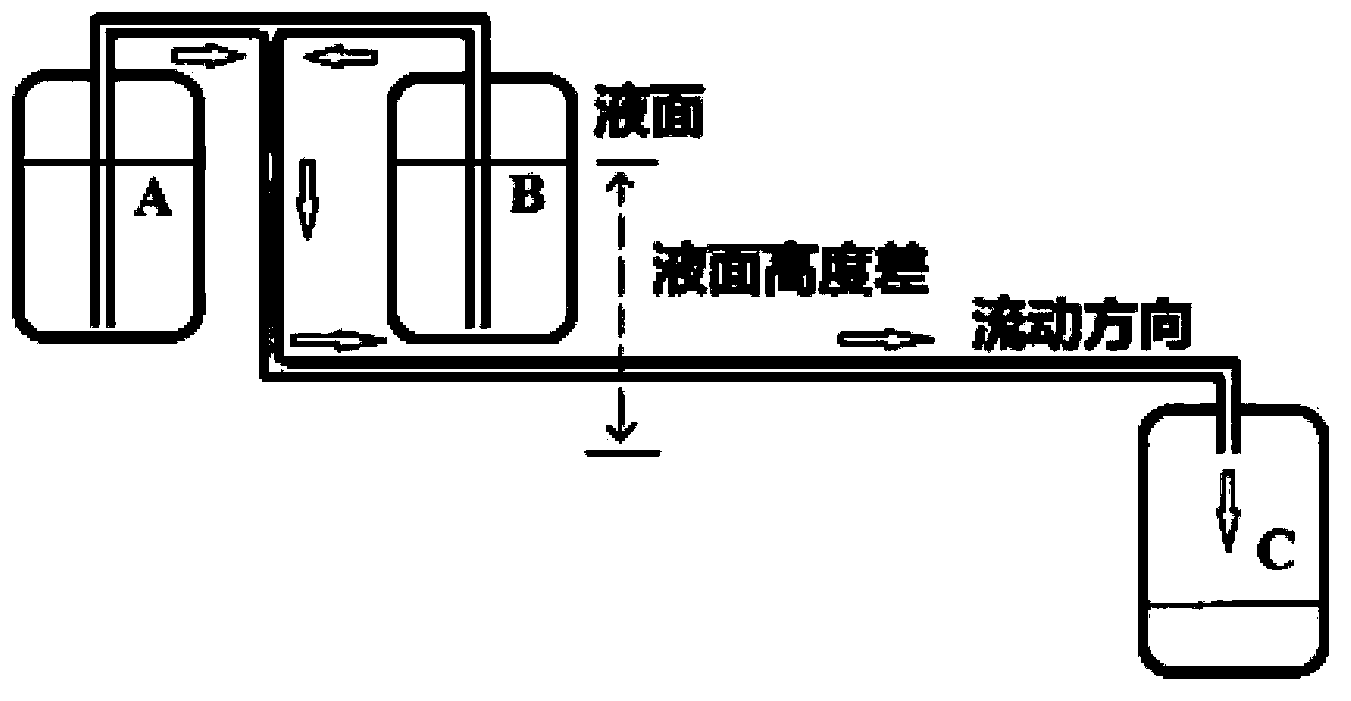

[0027] Accurately weigh 0.2794g of aniline and 0.1712g of ammonium persulfate, and add them into two flasks containing 100ml of 1mol / L hydrochloric acid solution respectively. After fully dissolving, it was introduced into a reaction tube with an inner diameter of 1.25mm and a length of 100cm, and the reaction product was collected in a beaker filled with 5% acetone aqueous solution. Adjust the height difference between the liquid level in the flask and the end of the reaction tube (see figure 1 ), control the flow rate at 20ml / h. After the flow was completed, the beaker was left to stand at room temperature for 2 h. After repeated washing, high-speed centrifugation and drying of the reaction product, polyaniline nanofibers with a diameter of 45 ± 5 nm and a length of 700 ± 50 nm (see figure 2 ).

Embodiment 2

[0029] Accurately weigh 0.0931g of aniline and 0.0338g of potassium persulfate, and add them into two flasks containing 100ml of 1mol / L camphorsulfonic acid solution respectively. After fully dissolving, introduce it into a reaction tube with an inner diameter of 0.7mm and a length of 400cm, and collect the reaction product in a beaker filled with a mixed solution of 20% acetone and ethanol (the volume ratio of acetone and ethanol is 1:0.1). Adjust the height difference between the liquid level in the beaker and the end of the reaction tube to control the flow rate at 5ml / h. After the flow was completed, the beaker was left to stand at room temperature for 6 h. After repeated washing, high-speed centrifugation and drying of the reaction product, polyaniline nanofibers with a diameter of 35 ± 10 nm and a length of 1 μm ± 200 nm (see image 3 ).

Embodiment 3

[0031] Accurately weigh 1.8624g of aniline and 10.812g of ferric chloride, and add them into two flasks containing 100ml of 0.5mol / L hydrochloric acid solution respectively. After fully dissolving, introduce it into a reaction tube with an inner diameter of 2 mm and a length of 50 cm, and collect the reaction product in a beaker filled with 50% acetone and ethanol aqueous solution (the ratio of acetone and ethanol is 1:0.01). Adjust the height difference between the liquid level in the flask and the end of the reaction tube, and set the flow rate at 100ml / h. After the flow was completed, the beaker was allowed to stand at room temperature for 8 h. After repeated washing, high-speed centrifugation and drying of the reaction product, polyaniline nanofibers with a diameter of 50 ± 10 nm and a length of 300 ± 100 nm (see Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com