Aeroengine combustor rotational sliding arc plasma combustion-supporting actuator

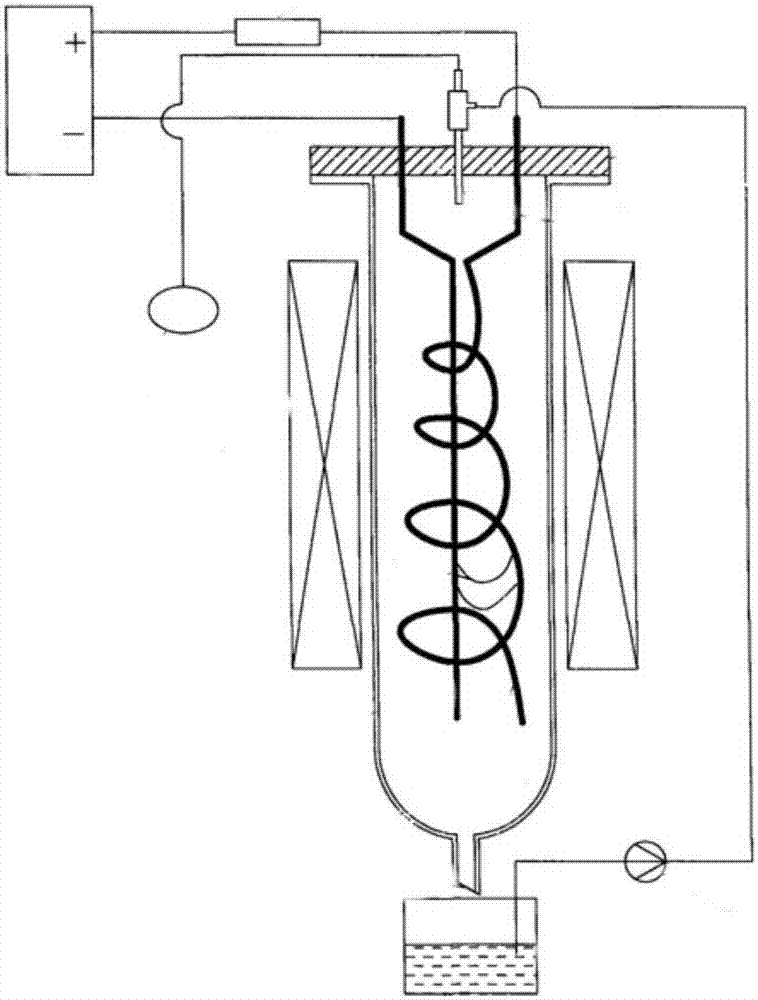

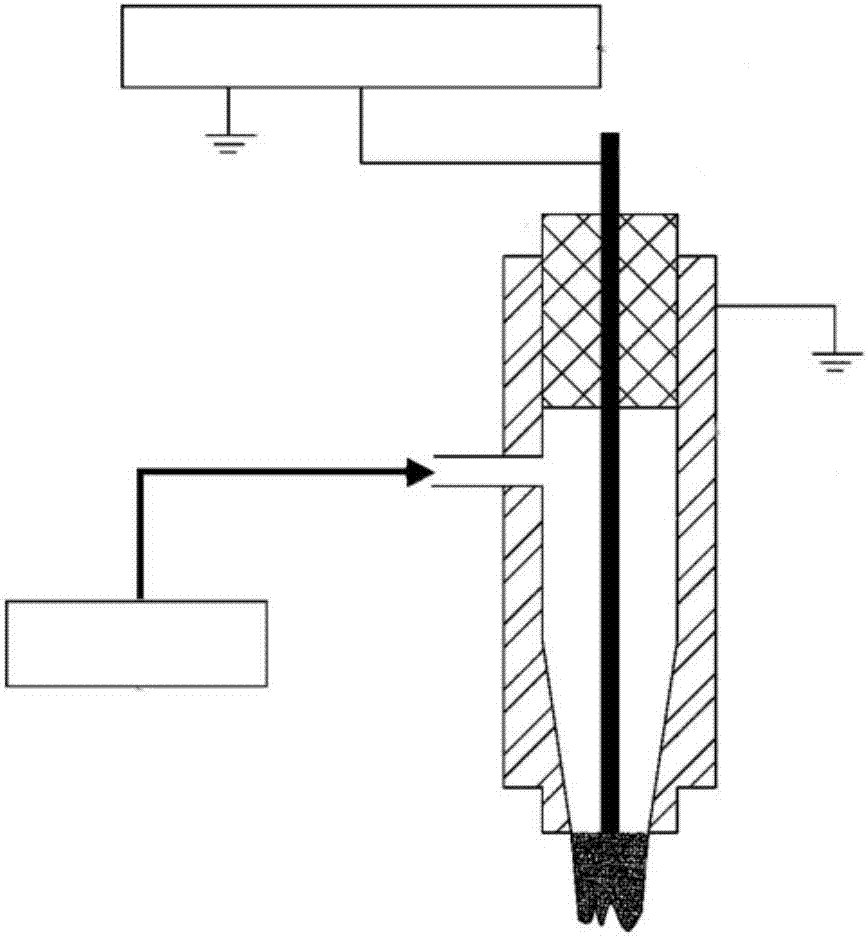

A technology of aero-engine and plasma, which is applied in the direction of plasma, machine/engine, mechanical equipment, etc. It can solve the problems of complex structure, inability to adapt to the harsh working environment of the aero-engine combustion chamber, and large size, so as to improve combustion efficiency, Simplified geometry and dynamics, small size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

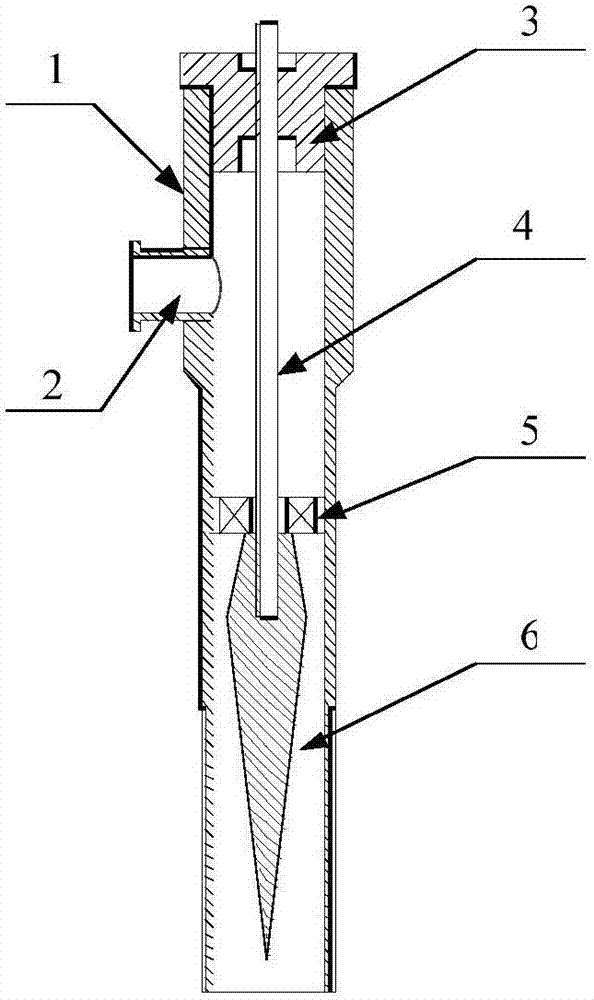

[0035] This embodiment is a rotary sliding arc plasma combustion-supporting exciter for an aero-engine combustor, including an anode casing 1, an air intake nozzle 2, an electrode installation isolation seat 3, a cathode electrode rod 4, a swirler 5 and a cathode cone electrode 6. Wherein, the cyclone 5 is located in the middle section of the inner hole of the anode casing 1 . The cathode cone electrode 6 is located below the round-hole axial flow cyclone; the lower end of the cathode electrode rod 4 passes through the central hole of the round-hole axial flow cyclone 5 and is inserted into the cathode cone In the central blind hole on the upper end face of the body electrode; the upper end of the cathode electrode rod is put into the center hole of the electrode installation isolation seat 3, and the upper end of the cathode electrode rod extends out of the upper surface of the electrode installation isolation seat. The electrode installation isolation seat 3 is fixedly inst...

Embodiment 2

[0044] This embodiment is a rotary sliding arc plasma combustion-supporting exciter for an aero-engine combustor, including an anode casing 1, an air intake nozzle 2, an electrode installation isolation seat 3, a cathode electrode rod 4, a swirler 5 and a cathode cone electrode 6.

[0045] This embodiment is a rotary sliding arc plasma combustion-supporting exciter for an aero-engine combustor, including an anode casing 1, an air intake nozzle 2, an electrode installation isolation seat 3, a cathode electrode rod 4, a swirler 5 and a cathode cone electrode 6. Wherein, the cyclone 5 is located in the middle section of the inner hole of the anode casing 1 . The cathode cone electrode 6 is located below the vane-type axial flow swirler; the lower end of the cathode electrode rod 4 passes through the central hole of the swirler 5 and is inserted into the center of the upper end surface of the cathode cone electrode. In the blind hole; the upper end of the cathode electrode rod i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com